Preparation method of fresh collagen casing

A collagen, fresh-type technology, applied in sausage casings, fibrous casings, slaughtering, etc., can solve the problems of hard chewing, bad taste of casings, broken casings, etc., to achieve good taste and improved light transmittance of casings , the effect of thin casing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

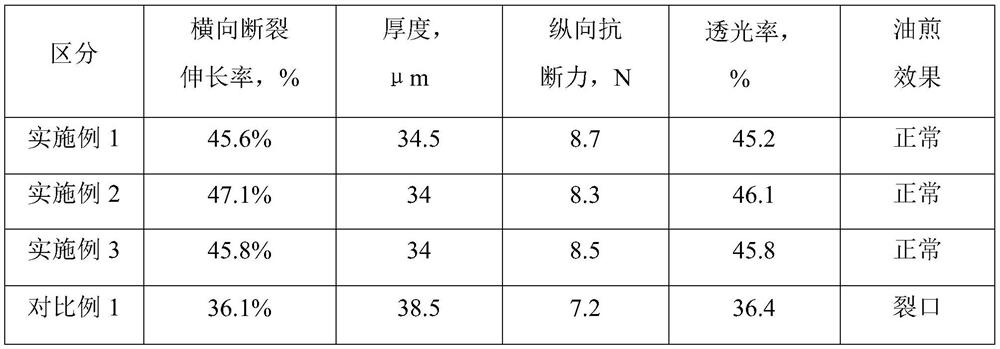

Examples

Embodiment 1

[0026] A preparation method for fresh type collagen casings, comprising the following steps:

[0027] (1) Use 1-year-old steer hides with a medium thickness of 6mm for the head;

[0028] (2) The leather is marinated at 20°C for 40 days;

[0029] (3) Ash-washing, acidifying, and defibrating the pickled leather to obtain collagen fibers;

[0030] (4) Add nanocellulose to the collagen fibers (the amount of nanocellulose is calculated according to the prepared collagen group, accounting for 3%) to obtain the collagen group, then filter and comb, and blow the casing to obtain the raw material. The moisture content of fresh collagen sausage casing is controlled at 91%.

Embodiment 2

[0032] A preparation method for fresh type collagen casings, comprising the following steps:

[0033] (1) Use 2-year-old steer hides with a medium thickness of 8mm for the head;

[0034] (2) The leather is marinated at 10°C for 90 days;

[0035] (3) Ash-washing, acidifying, and defibrating the pickled leather to obtain collagen fibers;

[0036] (4) Add nanocellulose to the collagen fibers (the amount of nanocellulose is calculated according to the prepared collagen group, accounting for 5%) to obtain the collagen group, then filter and comb, and blow the casing to obtain the raw material. The moisture content of fresh collagen sausage casing is controlled at 91%.

Embodiment 3

[0038] A preparation method for fresh type collagen casings, comprising the following steps:

[0039] (1) Use 1-year-old steer hides with a medium thickness of 7mm for the head;

[0040] (2) The leather is marinated at 15°C for 55 days;

[0041] (3) Ash-washing, acidifying, and defibrating the pickled leather to obtain collagen fibers;

[0042] (4) Add nanocellulose to the collagen fibers (the amount of nanocellulose is calculated according to the prepared collagen group, accounting for 4%) to obtain the collagen group, then filter and comb, and blow the sausage casing to obtain the raw material. The moisture content of the fresh collagen sausage casing is controlled at 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com