Cotton topping residual body disinfecting and recycling machine

A recycling machine and residue technology, which is applied in the field of cotton topping residue disinfection recycling machine, can solve the problems of abnormal growth of cotton, low recycling rate of cotton top residue, uneven top height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

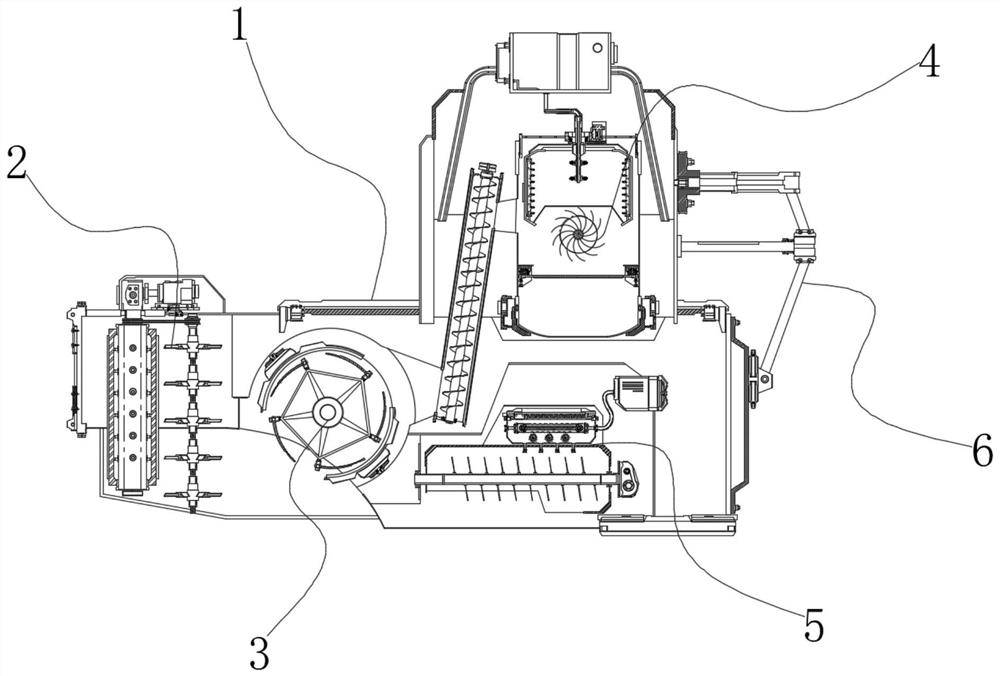

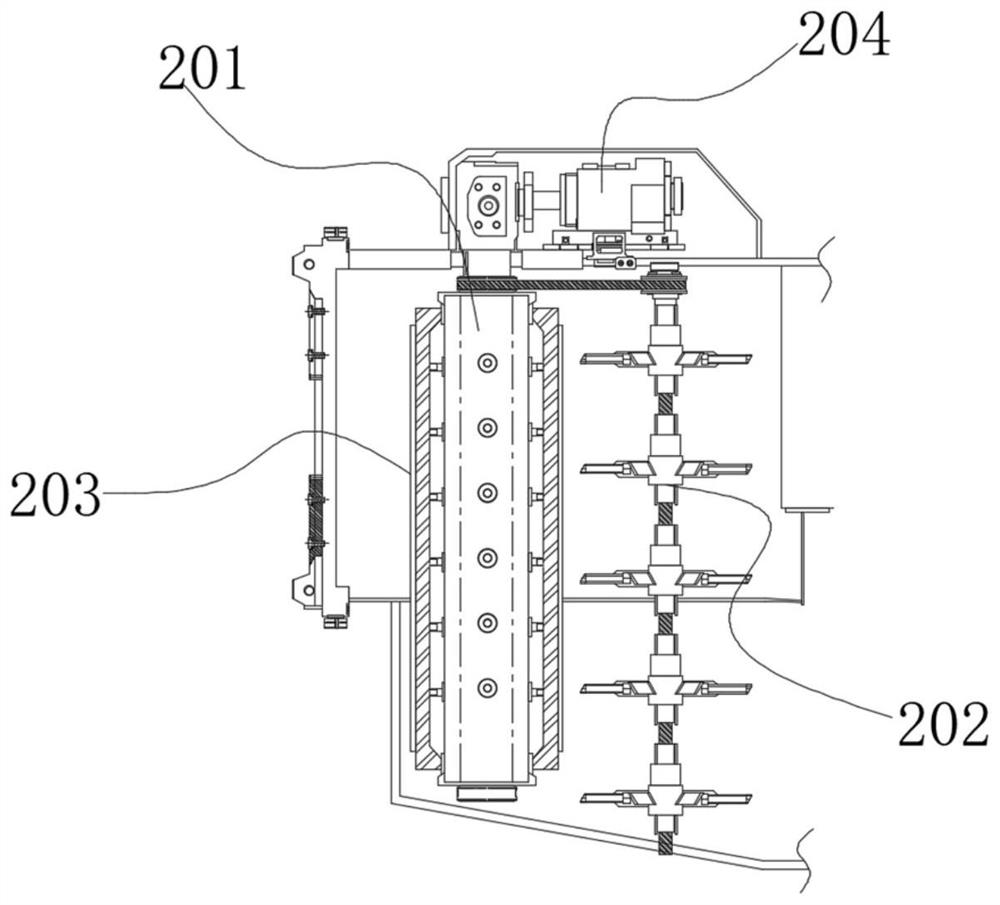

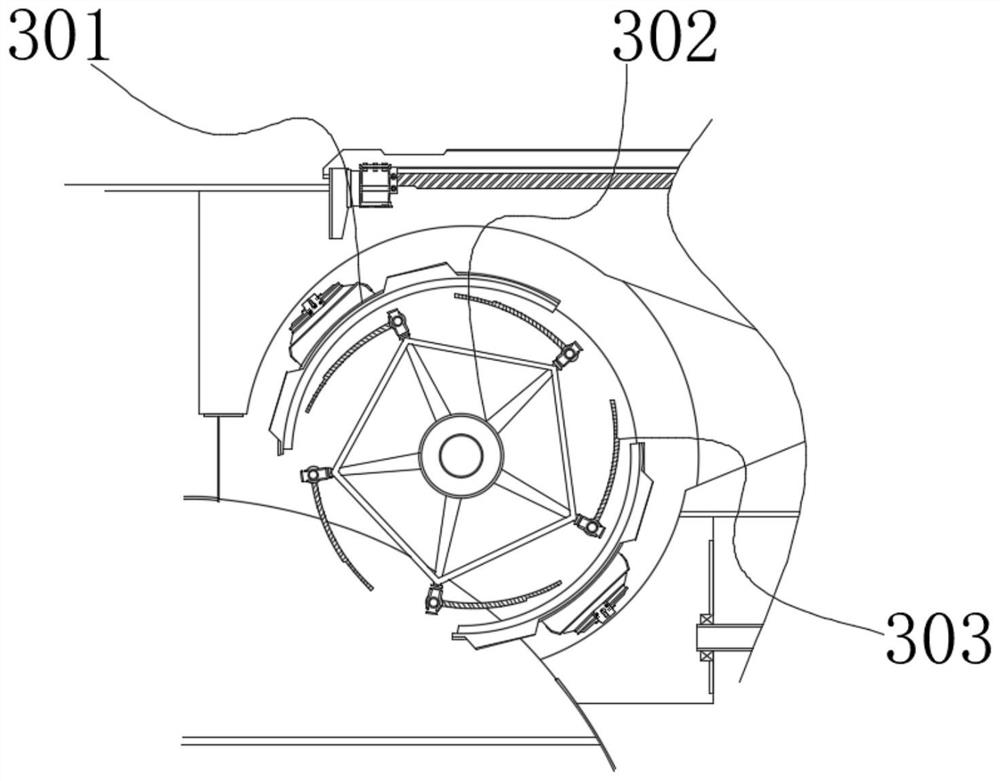

[0029] refer to figure 1 , the present invention provides a technical solution: a cotton topping residue disinfection recovery machine, which includes a main working body 1, a connecting bracket 6, a primary beam splitting assembly 2, a topping device 3, a residue disinfection recovery assembly 4 and a plant The billet end disinfection assembly 5, wherein, the end surface of one side of the main working body 1 and its lower side are provided with a topping feeding port for feeding the planted cotton branches, and the other side of the main working body 1 is fixed laterally with Connect the bracket 6, and fix it with the peripheral drive vehicle (not shown in the figure) through the connected bracket 6, so that the main working body 1 is flush with the height of the vertical distance from the ground of the planted cotton branch length, and is in contact with the top of the cotton , the inside of the main working body 1 is vertically provided with a preliminary beam splitting as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com