A magnetic generation anti-dismantlement component and a magnetic generation anti-dismantlement self-destruction device

A technology of anti-disassembly and components, which is applied in the electronic field, can solve the problems that the disassembly of the vehicle-mounted unit cannot be detected, whether the vehicle-mounted unit cannot detect whether it has been disassembled, and the chip is powered off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

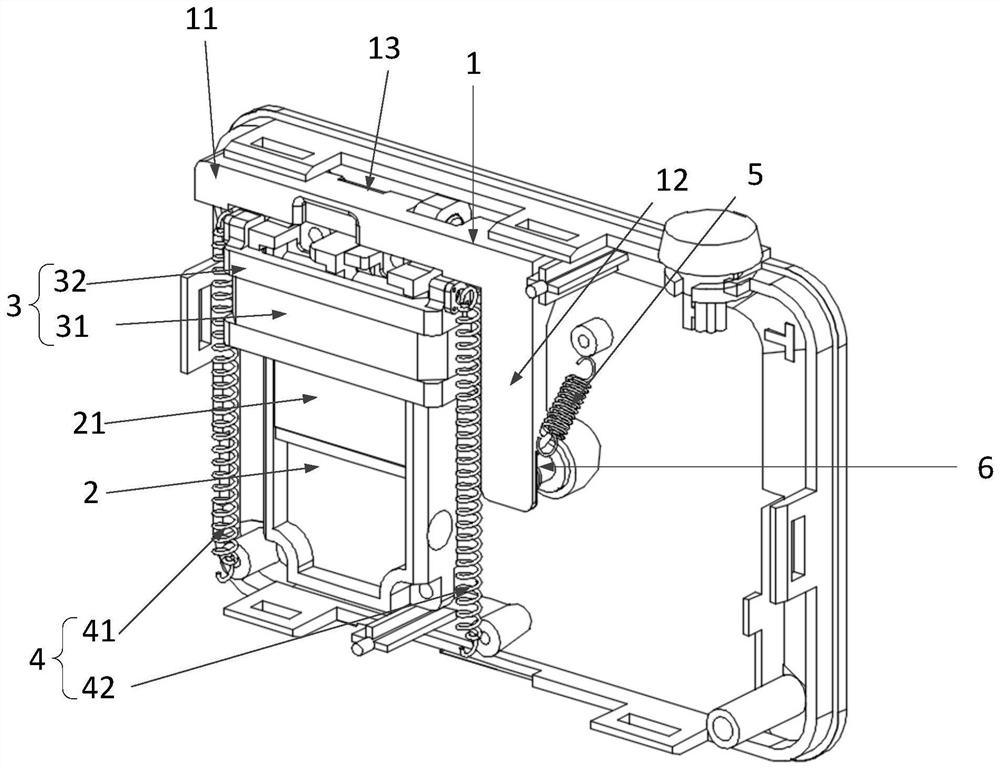

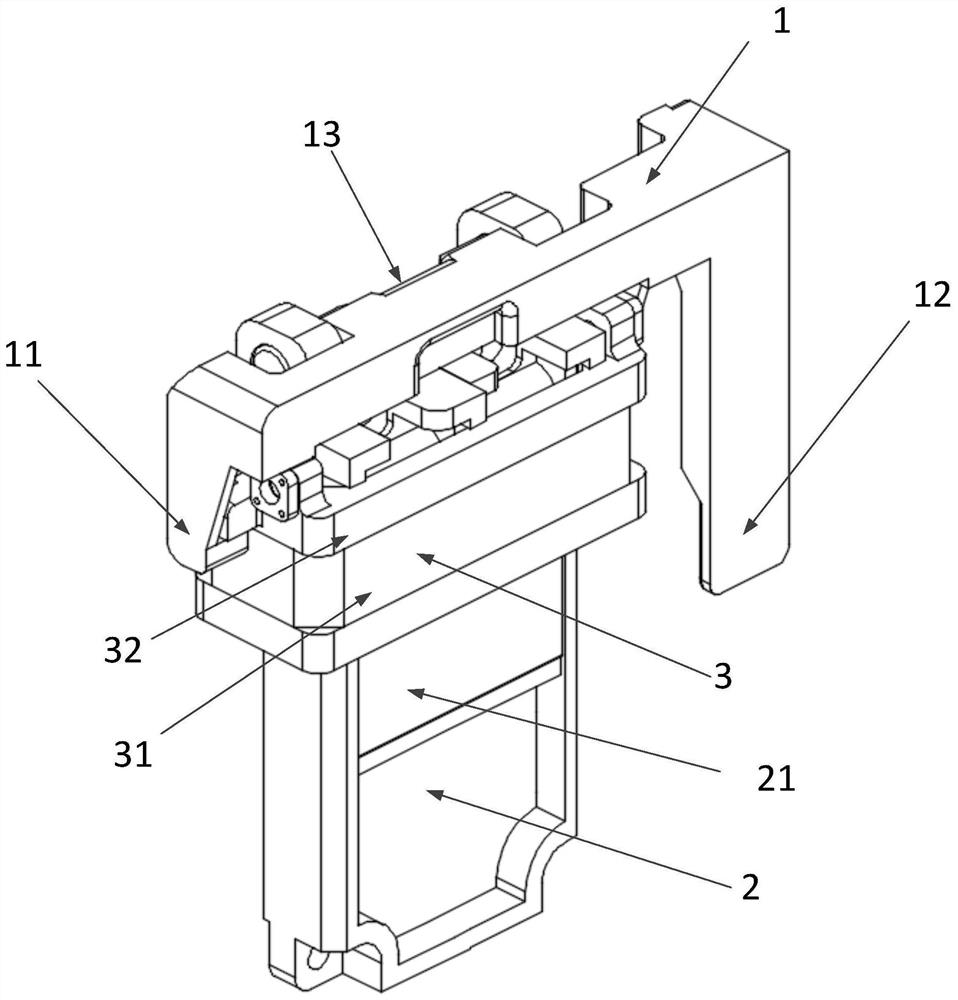

[0025] This embodiment provides a magnetic generator anti-dismantle assembly, which can be installed inside the equipment waiting to be installed on the vehicle-mounted unit (OBU), and is used for anti-dismantlement of electronic equipment. figure 1 It is a three-dimensional view of the magnetic generator anti-dismantlement assembly assembled into the equipment to be installed, figure 2 It is a three-dimensional view of a part of the magnetic generator tamper assembly ( figure 2 The first elastic part 4, the second elastic part 5 and the tamper bar 6) are not shown. Such as figure 1 As shown, the anti-tamper assembly of the magnetic generator includes: a rotating part 1 , a magnetic core part 2 , a coil part 3 , a first elastic part 4 , a second elastic part 5 and an anti-tamper rod 6 .

[0026] The rotating part 1 includes a hook plate 11, a pressing plate 12 and a rotating shaft 13, and the rotating shaft 13 is fixed on the magnetic core part 2 or the equipment to be ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com