Workpiece surface ultrasonic phased array automatic detection device

An automatic detection device, ultrasonic phased array technology, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. Bonding, easy damage of the inner lining and other problems, to achieve the effect of simple and convenient detection process, fast and accurate detection, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

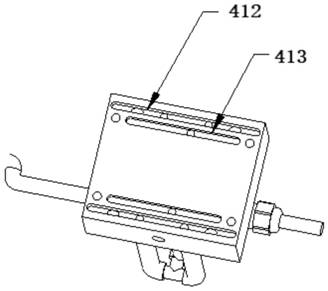

[0057] Such as figure 1 as shown, figure 1 It is a structural diagram of an ultrasonic phased array automatic detection device for pipeline lining. figure 2 It is a structure diagram of a pipe lining ultrasonic phased array automatic detection device for detecting pipelines.

[0058] The workpiece surface ultrasonic phased array automatic detection device includes a crawler 1, a scanning guide rail 2, an ultrasonic phased array instrument, and a motion controller;

[0059] The crawler 1 is arranged on the workpiece to be detected, and enables the crawler to move on the workpiece to be detected. One end of the crawler is arranged on a scanning guide rail, and an ultrasonic phased array instrument is arranged on the scanning guide rail. The scanning guide rail is arranged on the surface of the workpiece to be measured, so that the ultrasonic phased array instrument can realize coupling contact with the surface of the workpiece to be measured through a coupling agent, and coll...

Embodiment 2

[0095] The workpiece surface ultrasonic phased array automatic detection device provided in this embodiment can be used for the detection of debonding of the pipeline lining, and can also be used for the detection of debonding of other workpiece surfaces. This embodiment uses the pipeline as an example to illustrate the working process of the device , the work process described works as follows:

[0096] First, the ultrasonic phased array automatic detection device for debonding of the pipeline lining is adsorbed on the surface of the steel pipe, and the automatic detection pipeline crawler is adjusted so that the magnetic wheel and the workpiece are adsorbed stably; The detection device is used to detect the collection of information on the debonding state of the steel pipe lining. The device is adsorbed on the surface of the steel pipe. By adjusting the pipeline crawler, the magnetic wheel and the workpiece are adsorbed, so that the device is stably installed on the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com