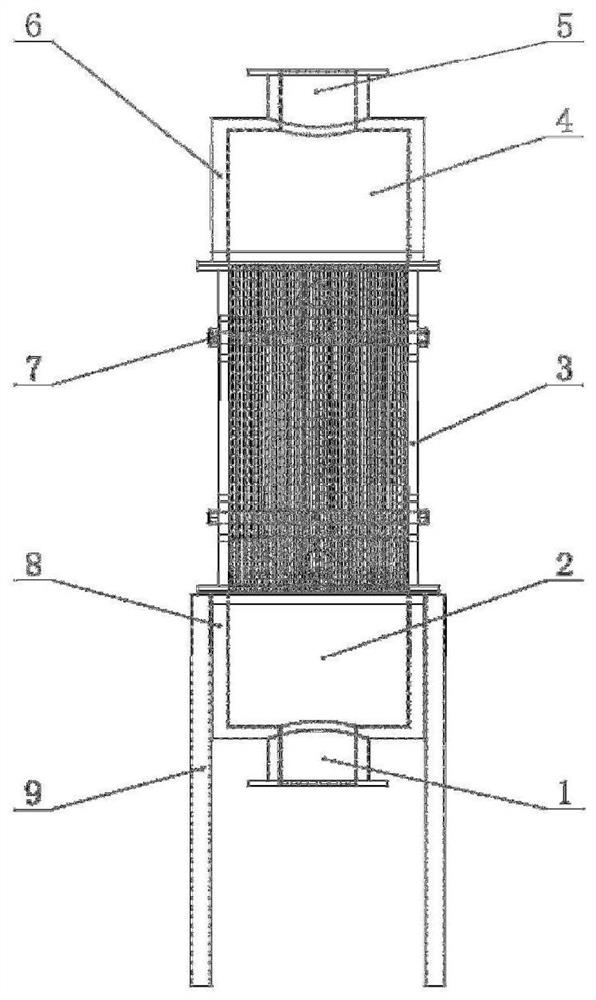

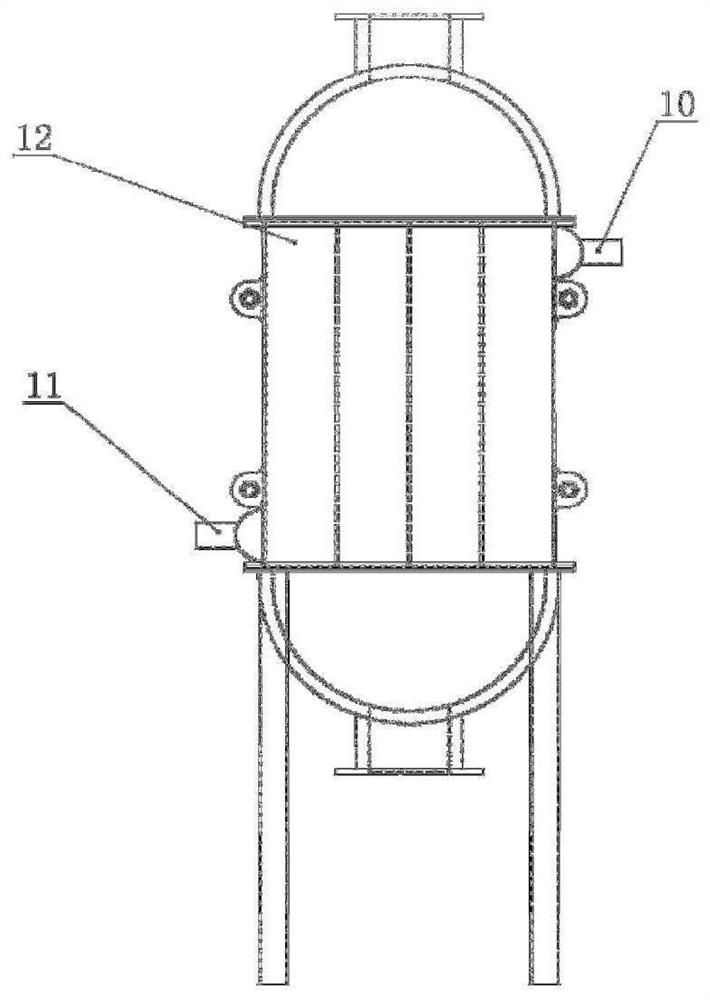

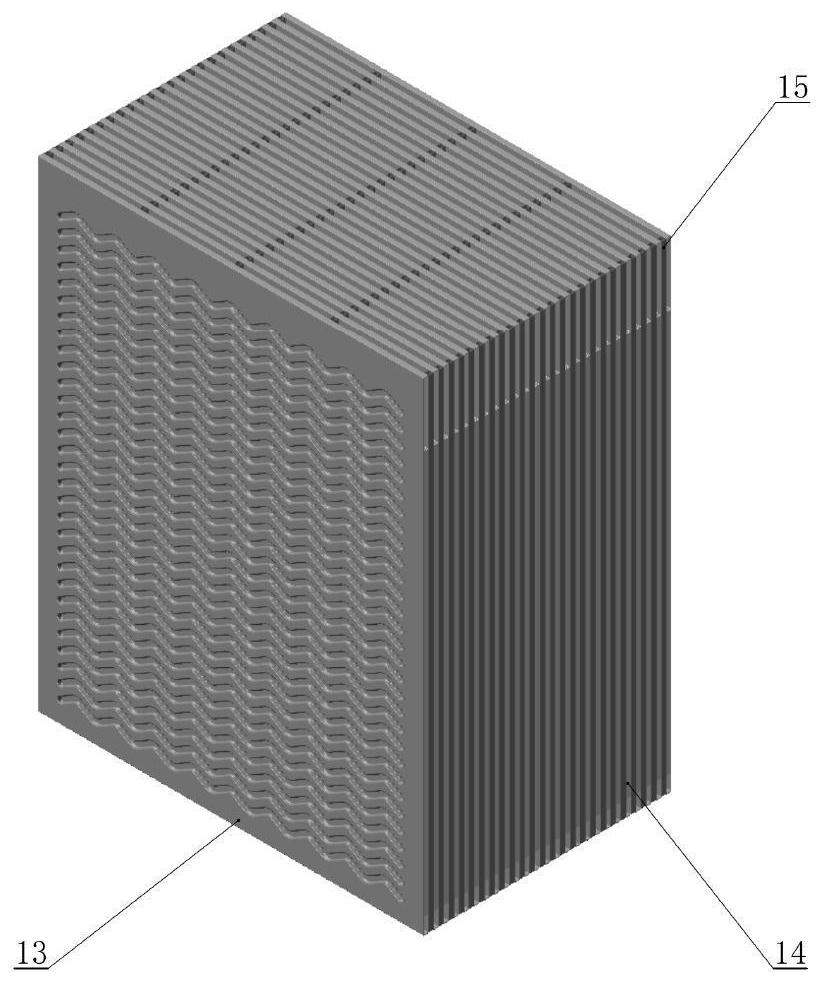

High-temperature gas-liquid plate heat exchanger resistant to sudden temperature change

A technology for sudden temperature changes and high-temperature gas, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc. Welding plate is easy to break and other problems, to achieve the effect of increasing the actual heat exchange area, improving energy utilization rate, and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The heat-carrying flue gas at 70-100°C is passed into the upper head 4 from the gas inlet 5 at a speed of 1.0-10.0m / s, and enters the heat-exchanging fin module 12 from the bend of the heat-exchanging plate 13, with a speed of 0.1-1.0m / s. m / s The liquid entering the heat exchange fin module 12 flows in opposite directions for heat exchange, and the heat exchanged liquid is discharged from the liquid outlet 10 for heat supply, and the heat exchange efficiency is over 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com