Array type silencer for main exhaust fan with large air volume and strong mixed noises

A technology of mixed noise and main exhaust fan, which is applied to the components of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., can solve the problems of unsatisfactory noise reduction, high regeneration noise, loud noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

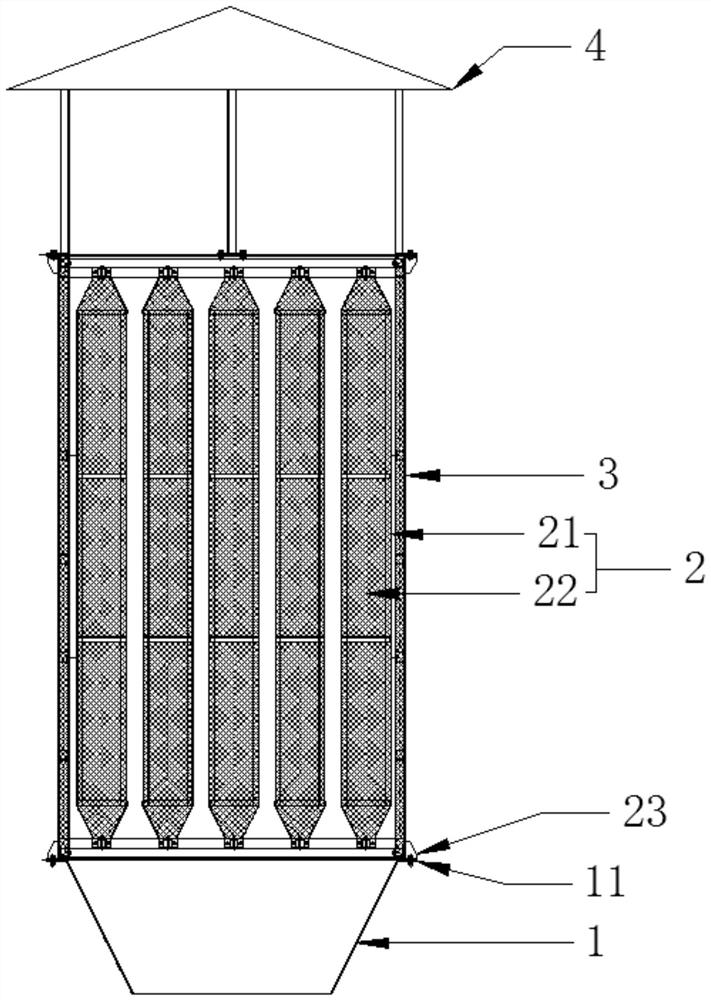

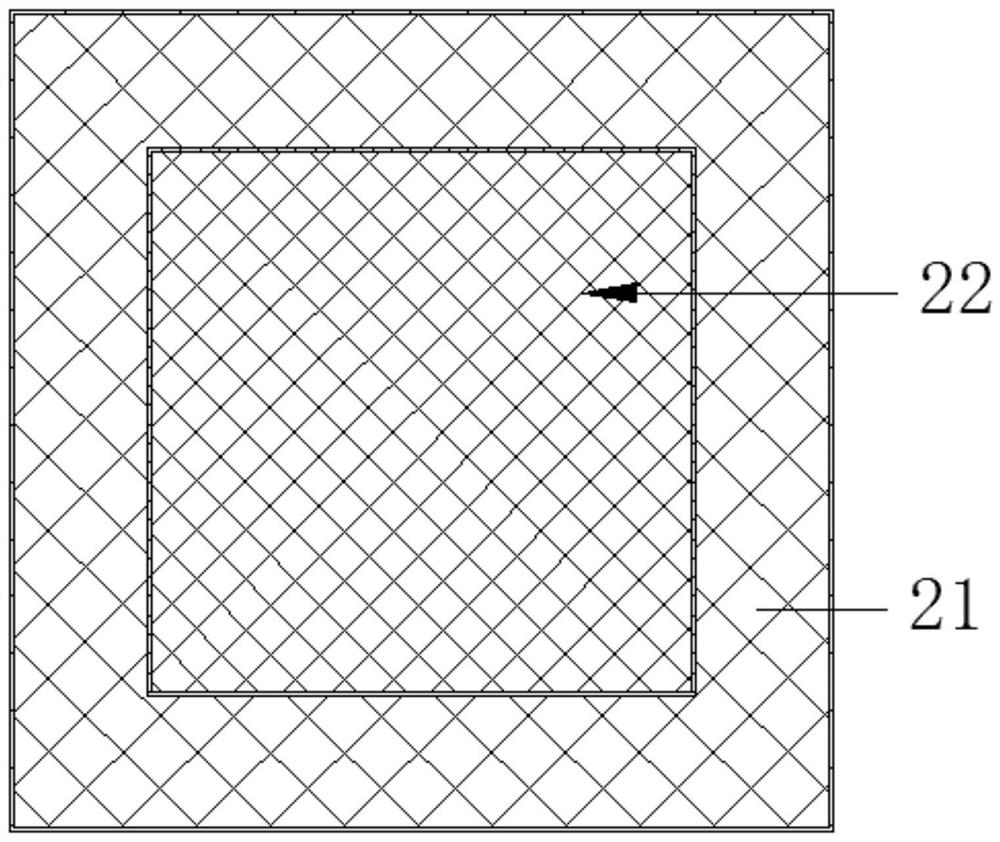

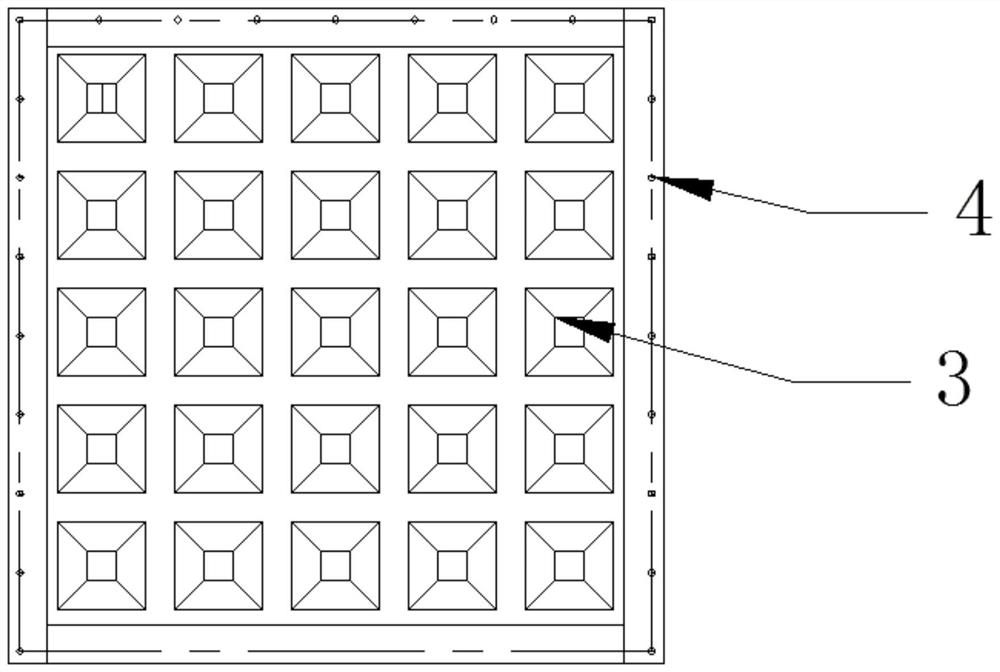

[0021] An array muffler for main exhaust fans with large air volume and strong mixed noise, such as figure 1 , 2 As shown in and 3, it includes variable-diameter air duct 1, matrix muffler unit 2, muffler shell 4 and rainproof cap 5; the matrix muffler unit 2 includes guides at both ends of muffler unit 2 and The flow head 3, the noise-absorbing unit 2 is composed of a sound-absorbing board and a sound-absorbing cotton 22.

[0022] The diversion head 3 is conical, and the thickness of the diversion head 3 is 2 mm.

[0023] The muffler shell 4 has a thickness of 4 mm, and supports are arranged inside, and the thickness of the supports is not less than 2 mm, and the distance between the supports is 600 mm.

[0024] The sound-absorbing cotton 22 adopts 48k glass wool.

[0025] The outer layer of the sound-absorbing board adopts a perforated board ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com