Power supply and distribution method for long-distance small-diameter tunnel secondary lining construction

A small-diameter, long-distance technology, applied in electrical components, earthwork drilling, circuit devices, etc., can solve problems such as the inability to meet the power supply requirements of the secondary lining construction of long-distance small-diameter tunnels, and achieve long-distance power supply voltage drop and The effect of small tunnel space limitation, guarantee of normal operation and normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

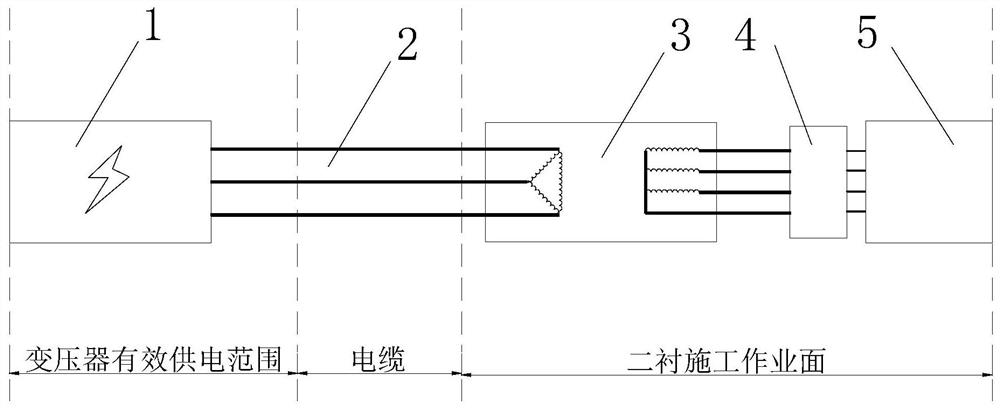

[0023] Such as figure 1 As shown, it is a schematic diagram of the composition of the power supply and distribution system of the present invention. The power supply system is mainly composed of a mains transformer 1, a main cable 2, a rail-type automatic boosting and stabilizing device 3, a low-voltage distribution trolley 4 and a second lining construction Electrical equipment.

[0024] The entire power supply and distribution process consists of two stages. The first stage is the normal power supply range of the mains transformer 1. The electric energy passes through the main cable 2 through the first-level distribution box outside the cave to the low-voltage distribution trolley 4, and then through the low-voltage distribution The secondary distribution box and the tertiary distribution box on the trolley 4 to the electrical equipment 5 for the construction of the second lining; the second stage is beyond the normal power supply range of the mains transformer 1, and the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com