Low-rare-earth high-strength wrought magnesium alloy containing neodymium and yttrium and preparation method of low-rare-earth high-strength wrought magnesium alloy

A deformed magnesium alloy, high-strength technology, applied in the field of magnesium alloys, can solve the problems of poor yield strength and poor strength of deformed magnesium alloys, and achieve the effects of increasing strength, hindering growth, and facilitating popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

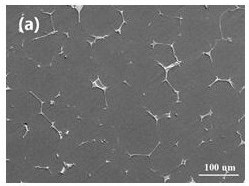

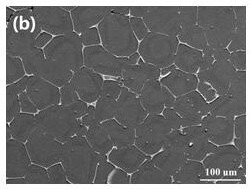

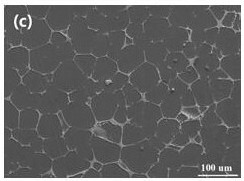

Image

Examples

Embodiment 1

[0023] Example 1: The low rare earth magnesium alloy containing neodymium and yttrium in this example includes (percentage by weight): Zn 5.67wt.%, Zr 0.47wt.%, Nd 0.45wt.%, Y 0.72wt. %, unavoidable impurities <0.10wt.%; the balance is Mg.

[0024] Its preparation method comprises the following steps:

[0025] a) Alloy melting and casting:

[0026] Casting by semi-continuous method, first put pure magnesium in a stainless steel crucible and preheat it to 200 ° C with the furnace, keep it for 1 hour; then pass in protective gas, in SF 6 +CO 2 Under the protection of gas, the induction furnace is heated up and melted; after the pure magnesium is melted, the temperature of the melt is raised to 720°C, and the preheated and dried Mg-Y and Mg-Nd master alloys are added to the magnesium melt. When adding, the intermediate alloy block should quickly enter below the liquid surface, and stir evenly after melting; when the temperature rises to 690°C, add pure zinc particles according...

Embodiment 2

[0031] Embodiment 2: The low rare earth magnesium alloy containing neodymium and yttrium in this embodiment includes the following components by weight percentage: Zn5.70wt.%, Zr 0.64 wt.%, Nd 0.48 wt.%, Y 0.73 wt.%, unavoidable Impurities <0.10wt.%; the balance is Mg.

[0032] Its alloy smelting and casting-machining-homogenization-hot extrusion-aging treatment methods are the same as in Example 1.

Embodiment 3

[0033] Embodiment 3: The low rare earth magnesium alloy containing neodymium and yttrium in this embodiment includes the following components by weight percentage: Zn6.40wt.%, Zr 0.59 wt.%, Nd 0.46 wt.%, Y 1.00 wt.%, unavoidable Impurities <0.10wt.%; the balance is Mg.

[0034] The method of alloy smelting and casting-machining-homogenization-hot extrusion-aging treatment is the same as that of Example 1, except that the extrusion ratio is 10:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com