Recovery method of aroma components in reconstituted tobacco condensed water, eluent formed by method, and application of eluent

A recovery method and technology for reconstituting tobacco leaves, applied in the directions of essential oils/spice, fat production, etc., can solve the problems of high cost and difficulty in recovering the aroma components of condensed water, improve purity, reduce sample loading and processing capacity, and process energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

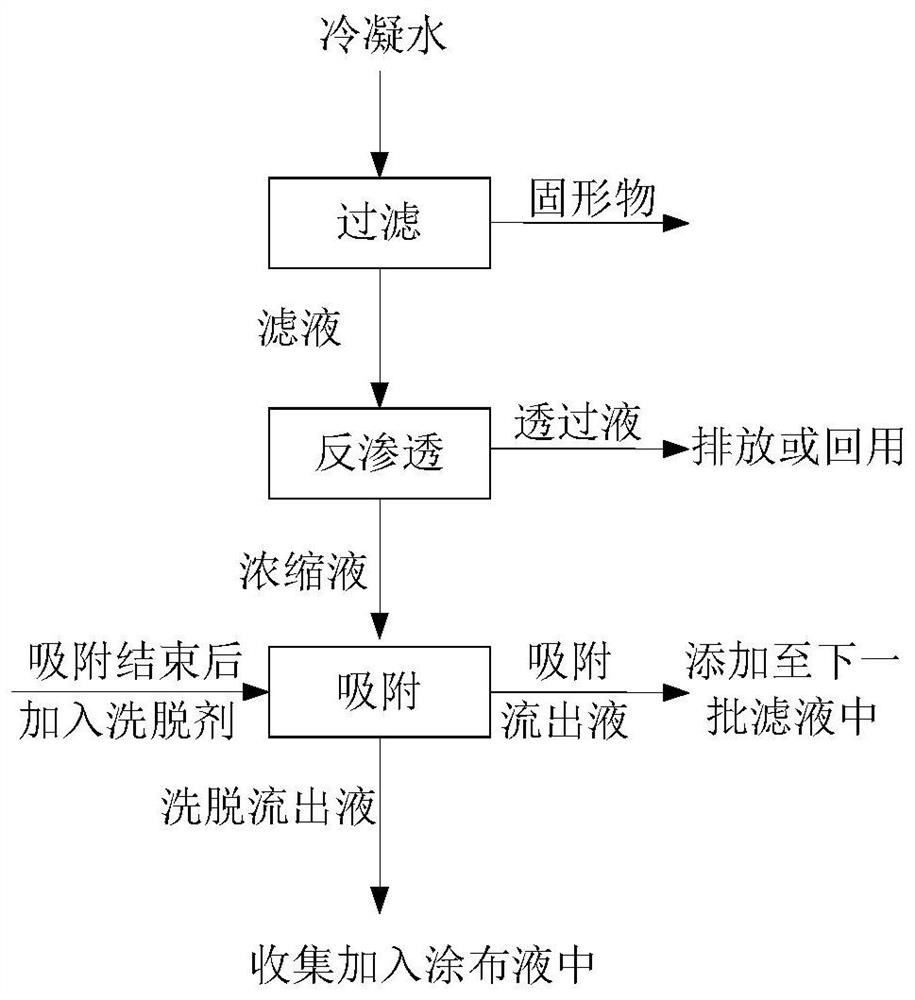

[0039] The method adopted in the embodiment of this application is as figure 1 As shown, the specific operation is as follows:

[0040] 1) Filtration treatment of reconstituted tobacco condensed water: the reconstituted tobacco condensed water is filtered with a plate and frame filter, and the filtrate enters reverse osmosis treatment; the mesh number of the filter screen of the plate and frame filter is 200-300 mesh;

[0041] 2) Concentration of reverse osmosis: use plate type reverse osmosis membrane equipment to initially concentrate the condensed water, the operating pressure is 1.0MPa, the concentration ratio is about 8.5 times, the permeate is directly discharged or reused in production, and the reverse osmosis concentrate is fixed in a macroporous resin bed for adsorption;

[0042] 3) Fixed bed adsorption: The concentrated liquid passes through the XAD-4 non-polar macroporous resin fixed bed of Rohm Hass Company at a flow rate of 5BV / h, and the effluent is collected an...

Embodiment 2

[0049] The method adopted in the embodiment of this application is as figure 1 As shown, the specific operation is as follows:

[0050] 1) Filtration treatment of reconstituted tobacco condensed water: the reconstituted tobacco condensed water is filtered with a plate and frame filter, and the filtrate enters reverse osmosis treatment; the mesh number of the filter screen of the plate and frame filter is 200-300 mesh;

[0051] 2) Concentration of reverse osmosis: use plate type reverse osmosis membrane equipment to preliminarily concentrate the condensed water, the operating pressure is 1.5MPa, the concentration ratio is about 5.2 times, the permeate is directly discharged or reused in production, and the reverse osmosis concentrate is fixed in a macroporous resin bed for adsorption;

[0052] 3) Fixed bed adsorption: The concentrated liquid passes through the fixed bed of HZ-814 weakly polar macroporous resin of Huazhen Technology Co., Ltd. at a flow rate of 3BV / h. The efflue...

Embodiment 3

[0059] The method adopted in the embodiment of this application is as figure 1 As shown, the specific operation is as follows:

[0060] 1) Filtration treatment of reconstituted tobacco condensed water: the reconstituted tobacco condensed water is filtered with a plate and frame filter, and the filtrate enters reverse osmosis treatment; the mesh number of the filter screen of the plate and frame filter is 200-300 mesh;

[0061] 2) Concentration of reverse osmosis: use plate-type reverse osmosis membrane equipment to preliminarily concentrate the condensed water, the operating pressure is 2.0MPa, the concentration ratio is about 8.2 times, the permeate is directly discharged or reused in production, and the reverse osmosis concentrate is fixed in a macroporous resin bed for adsorption;

[0062] 3) Fixed bed adsorption: The concentrated liquid passes through the HP-20 non-polar macroporous resin fixed bed of Mitsubishi Chemical Company at a flow rate of 4BV / h. After the effluent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com