Preparation method of ultralow-smoke algal polysaccharide material

A seaweed polysaccharide, ultra-low technology, applied in the field of preparation of ultra-low-smoke seaweed polysaccharide materials, can solve the problems of low silver loading rate, silver pressure, etc., and achieve the effect of simple process and strong antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

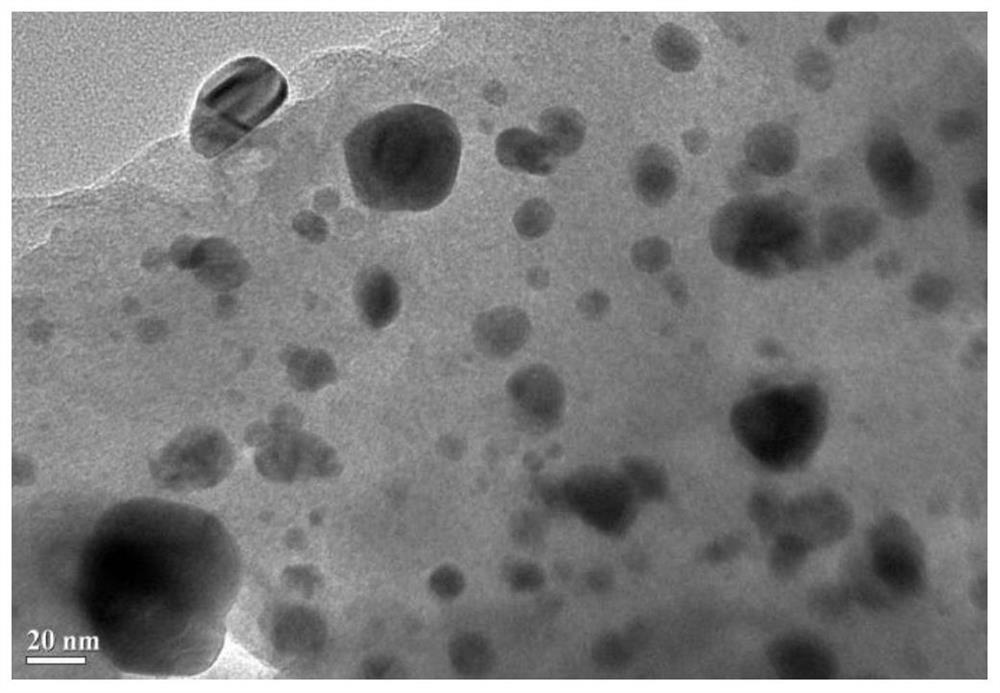

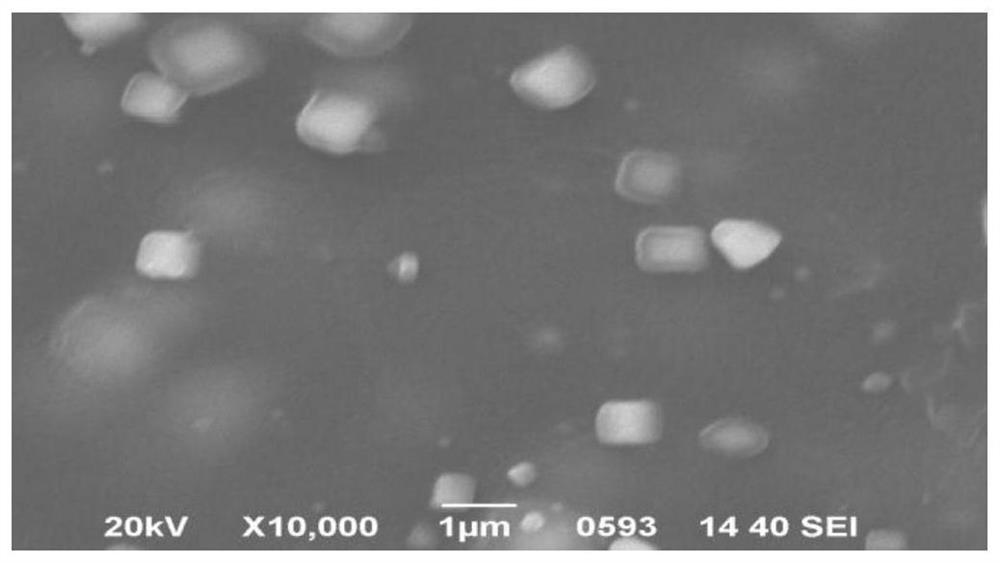

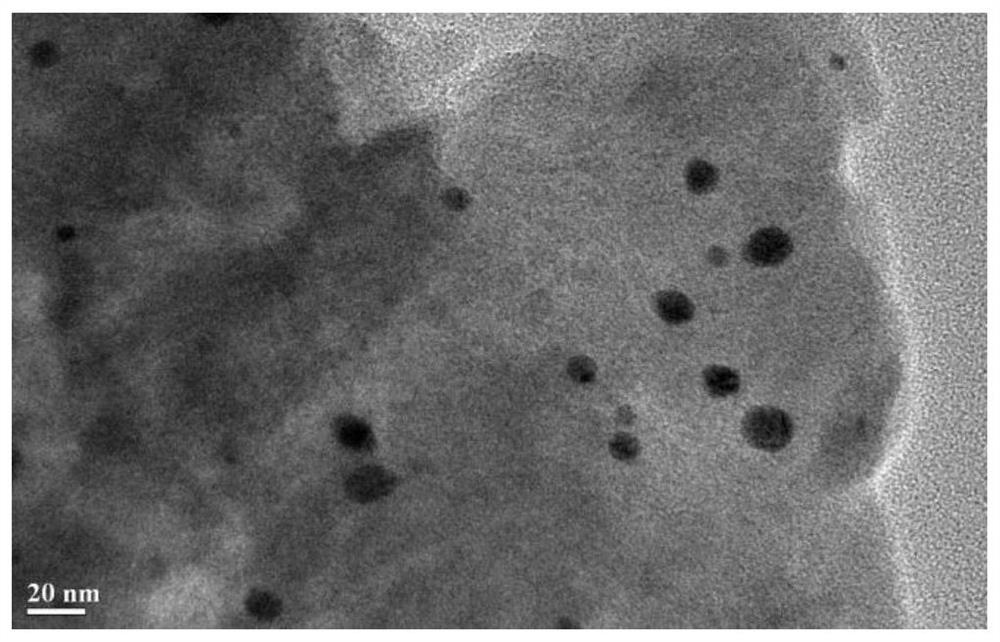

Image

Examples

Embodiment 1

[0039] (1) Sodium chloride, polyvinylpyrrolidone K90 with an average molecular weight ≥ 120,000, sodium alginate, and deionized water were formulated into solution A at a mass ratio of 1:0.2:20:450; specifically: first deionized Heat the water to 40°C, under the action of ultrasonic waves, dissolve polyvinylpyrrolidone K90, chloride and sodium alginate in sequence, and keep the reaction for 50 minutes to get it;

[0040] (2) Weigh silver nitrate equimolar with sodium chloride, then silver nitrate, 25% ammonia water, and deionized water are made into solution B according to the mass ratio of 1:5.5:6; Dissolve silver nitrate in water, then add 25% ammonia water dropwise into the silver nitrate solution under stirring conditions, and keep stirring for 4 minutes to obtain the product;

[0041] (3) Add solution B dropwise to solution A under heating and stirring in a water bath at 40°C, stop stirring when the reaction solution turns milky white, and keep it standing at a constant t...

Embodiment 2

[0044] (1) Potassium chloride, polyvinylpyrrolidone K90 with an average molecular weight ≥ 120,000, sodium alginate, and deionized water were formulated into solution A at a mass ratio of 1:0.1:15:400; specifically: first deionized Heat the water to 30°C, under the action of ultrasonic waves, dissolve polyvinylpyrrolidone K90, chloride and sodium alginate in sequence, and keep the reaction for 60 minutes to get it;

[0045] (2) Weigh silver nitrate equimolar with potassium chloride, then silver nitrate, 25% ammonia water, and deionized water are made into solution B according to the mass ratio of 1:5:5; Dissolve silver nitrate in water, then add 25% ammonia water dropwise into the silver nitrate solution under stirring conditions, and keep stirring for 3 minutes to obtain the product;

[0046] (3) Add solution B dropwise to solution A under heating and stirring in a water bath at 40°C, stop stirring when the reaction solution turns milky white, and keep it standing at a consta...

Embodiment 3

[0049] (1) Ammonium chloride, polyvinylpyrrolidone K90 with an average molecular weight ≥ 120,000, sodium alginate, and deionized water were formulated into solution A at a mass ratio of 1:0.3:25:500; specifically, deionized Heat the water to 50°C, under the action of ultrasonic waves, dissolve polyvinylpyrrolidone K90, chloride and sodium alginate in sequence, and keep the reaction for 30 minutes to get the product;

[0050] (2) Weigh silver nitrate equimolar with ammonium chloride, then silver nitrate, 25% ammonia water, and deionized water are made into solution B according to the mass ratio of 1:6:7; Dissolve silver nitrate in water, then add 25% ammonia water dropwise into the silver nitrate solution under stirring conditions, and keep stirring for 5 minutes to obtain the product;

[0051] (3) Add solution B dropwise to solution A under heating and stirring in a water bath at 40°C, stop stirring when the reaction solution turns milky white, and keep it standing at a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com