Formaldehyde production energy-saving device and production process

An energy-saving device and formaldehyde technology, which is applied in the preparation of carbon-based compounds, organic compounds, chemical instruments and methods, etc., can solve the problems that affect the continuous and stable production, inflexible operation adjustment, short operation cycle, etc., and achieve good economy Benefits, short process flow, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

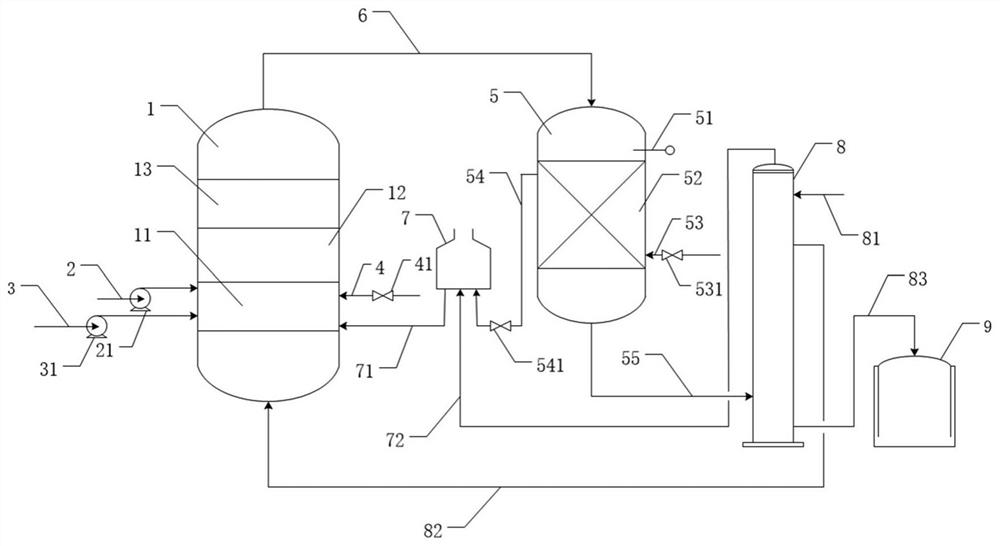

[0050] A formaldehyde production process, the steps are as follows:

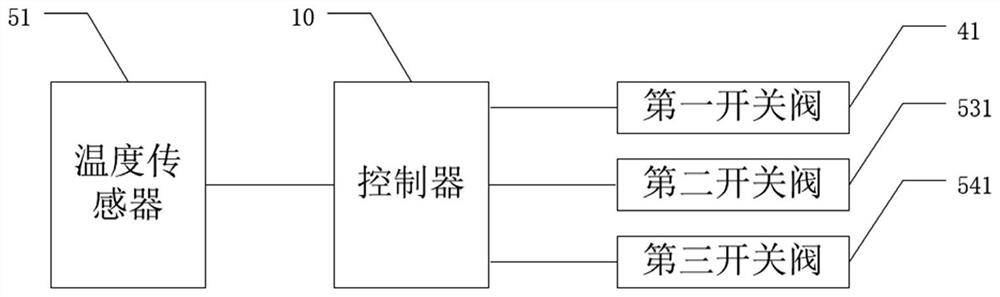

[0051] (1), methanol and air enter into the ternary gas processor 1 under the action of the Roots blower 21 and the vacuum pump 31 respectively, and at the same time, open the first switch valve 41, and water vapor enters the ternary gas processor 1 through the first steam pipeline 4 Mix uniformly inside to obtain a ternary mixed gas.

[0052] (2) The mixed ternary mixed gas enters the oxidizer 5, and under the catalysis of the silver catalyst, the oxidation reaction of methanol is carried out at a high temperature of 590° C. to obtain reaction gas.

[0053](3), the reaction gas is sent to the absorption tower 8, and the reaction gas is washed and absorbed by the absorption liquid, and the obtained formaldehyde solution is finally collected in the collection tank 9, and the tail gas produced is transported to the incinerator 7 for incineration Treatment, the unabsorbed aqueous methanol solution is discharge...

Embodiment 2

[0055] A formaldehyde production process, the steps are as follows:

[0056] (1), methanol and air enter into the ternary gas processor 1 under the action of the Roots blower 21 and the vacuum pump 31 respectively, and at the same time, open the first switch valve 41, and water vapor enters the ternary gas processor 1 through the first steam pipeline 4 Mix uniformly inside to obtain a ternary mixed gas.

[0057] (2) The mixed ternary mixed gas enters the oxidizer 5, and under the catalysis of the silver catalyst, the oxidation reaction of methanol is carried out at a high temperature of 610° C. to obtain reaction gas.

[0058] (3), the reaction gas is sent to the absorption tower 8, and the reaction gas is washed and absorbed by the absorption liquid, and the obtained formaldehyde solution is finally collected in the collection tank 9, and the tail gas produced is transported to the incinerator 7 for incineration Treatment, the unabsorbed aqueous methanol solution is discharg...

Embodiment 3

[0060] A formaldehyde production process, the steps are as follows:

[0061] (1), methanol and air enter into the ternary gas processor 1 under the action of the Roots blower 21 and the vacuum pump 31 respectively, and at the same time, open the first switch valve 41, and water vapor enters the ternary gas processor 1 through the first steam pipeline 4 Mix uniformly inside to obtain a ternary mixed gas.

[0062] (2) The mixed ternary mixed gas enters the oxidizer 5, and under the catalysis of the silver catalyst, the oxidation reaction of methanol is carried out at a high temperature of 600° C. to obtain a reaction gas.

[0063] (3), the reaction gas is sent to the absorption tower 8, and the reaction gas is washed and absorbed by the absorption liquid, and the obtained formaldehyde solution is finally collected in the collection tank 9, and the tail gas produced is transported to the incinerator 7 for incineration Treatment, the unabsorbed aqueous methanol solution is discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com