Intelligent enhanced production system and process of 1, 4-butanediol

A production system, butanediol technology, applied in organic chemistry, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of insufficient reaction in the hydrogenation section, incomplete catalyst reaction, and uniform hydrogen mixing, etc., to achieve improved Work efficiency and work quality, improve mixing quality and mixing efficiency, and ensure the effect of reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

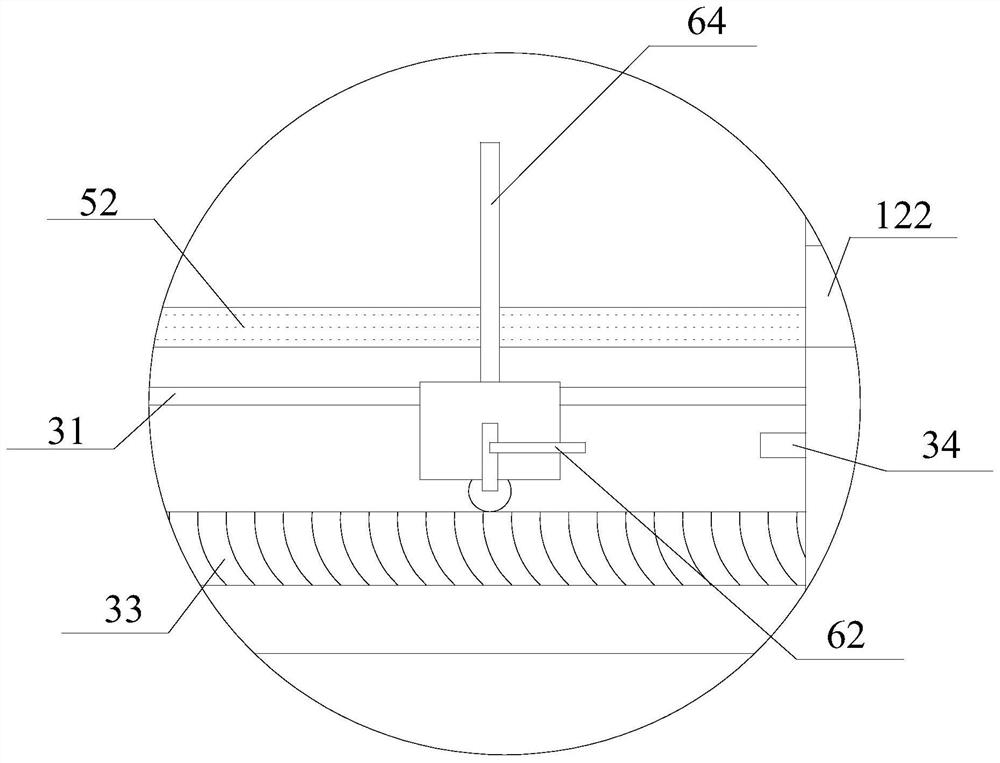

[0050] refer to Image 6 , a preparation process for preparing 1,4 butanediol using an intelligent intensified production system of 1,4 butanediol, comprising the following steps:

[0051] A. Add butadiene to the first reaction device 11 through the raw material feed pipe 111, and use the additive feed pipe 112 to add additives to the first reaction device 11. The additive is an iron-molybdenum catalyst, and the butadiene The ratio with iron molybdenum catalyst is 1:0.2;

[0052] B. During the reaction in step A, oxygen is added to the first reaction device 11 through the raw material feed pipe 111, and the oxygen content of the oxygen is 18%;

[0053] C, 1,4-diacetoxy and 2-butene are generated during the reaction in step B. In this reaction step, a Raney nickel catalyst needs to be added in the second reaction device 12, and the content of the Raney nickel catalyst accounts for is 0.5, the reaction temperature of this process is 20-70°C, and the reaction pressure is 0.1-0....

Embodiment 2

[0059] A kind of preparation technology that utilizes 1,4 butanediol intelligent strengthened production system to prepare 1,4 butanediol, comprises the following steps:

[0060] A. Add butadiene to the first reaction device 11 through the raw material feed pipe 111, and use the additive feed pipe 112 to add additives to the first reaction device 11. The additive is an iron-molybdenum catalyst, and the butadiene The ratio with iron molybdenum catalyst is 1:0.2;

[0061] B. During the reaction in step A, oxygen is added to the first reaction device 11 through the raw material feed pipe 111, and the oxygen content of the oxygen is 18%;

[0062] C, 1,4-diacetoxy and 2-butene are generated during the reaction in step B. In this reaction step, a Raney nickel catalyst needs to be added in the second reaction device 12, and the content of the Raney nickel catalyst accounts for is 0.5, the reaction temperature of this process is 20-70°C, and the reaction pressure is 0.1-0.8MPa;

[0...

Embodiment 3

[0068] A kind of preparation technology that utilizes 1,4 butanediol intelligent strengthened production system to prepare 1,4 butanediol, comprises the following steps:

[0069] A. Add butadiene to the first reaction device 11 through the raw material feed pipe 111, and use the additive feed pipe 112 to add additives to the first reaction device 12. The additive is an iron-molybdenum catalyst, and the butadiene The ratio with iron molybdenum catalyst is 1:0.2;

[0070] B. During the reaction in step A, oxygen is added to the first reaction device 11 through the raw material feed pipe 111, and the oxygen content of the oxygen is 18%;

[0071] C, 1,4-diacetoxy and 2-butene are generated during the reaction in step B. In this reaction step, a Raney nickel catalyst needs to be added in the second reaction device 12, and the content of the Raney nickel catalyst accounts for is 0.5, the reaction temperature of this process is 20-70°C, and the reaction pressure is 0.1-0.8MPa;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com