Cooling reactor having slag salvaging function and used for wastewater acid-base neutralization, and application of cooling reactor

A reactor and functional technology, which is applied in the field of cooling reactors for acid-base neutralization of wastewater, can solve problems such as affecting normal use, reducing the effect of sewage treatment, and clogging the reactor, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

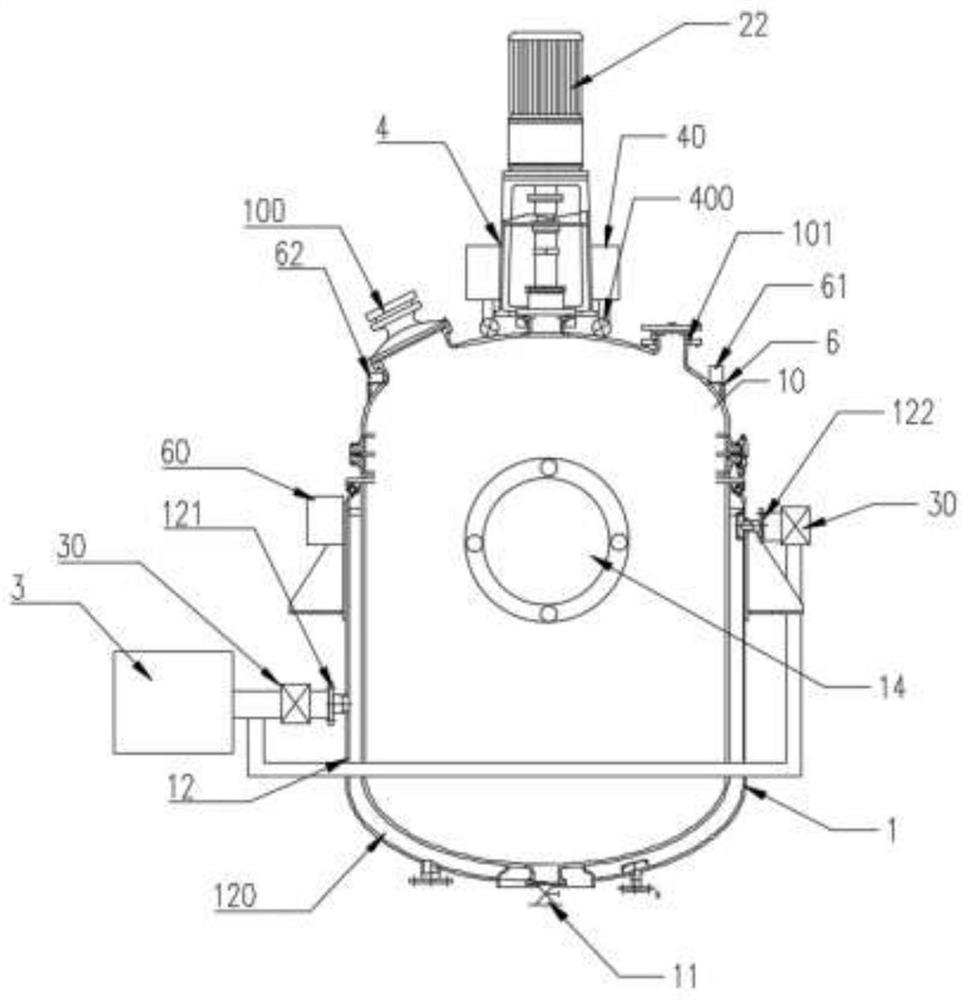

[0038] Example: such as figure 1 , 2 As shown, a cooling reactor for acid-base neutralization of waste water with the function of removing slag, including a tank body with a tank cover 10 connected to the upper end through a flange, a discharge port 11 at the bottom end, and a jacket 12 on the outer wall 1. Stirring and slag removing element 2 vertically installed in the tank body 1, cooling water tank for cooling the tank body 1 3, mist cooling and collecting element 4 for collecting acid and alkali mist in the tank body 1, volume control adding element 5 . An intelligent control element 6 for controlling the normal operation of each electrical component and a power supply for providing electrical energy to each electrical component;

[0039] A cooling cavity 120 is formed between the jacket 12 and the outer wall of the tank body 1, and the side wall of the jacket 12 is provided with a cooling water inlet 121 and a cooling water outlet 122;

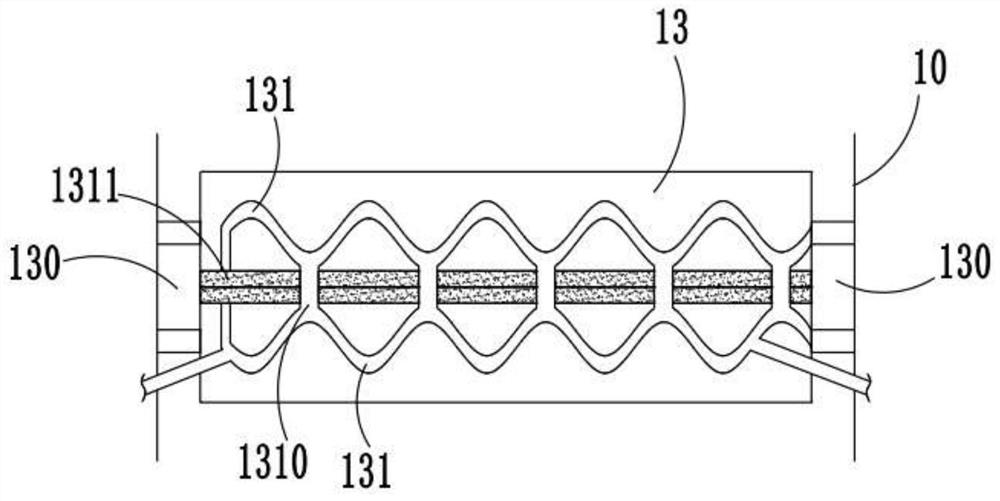

[0040] Such as image 3 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com