Hot-pressing bonding equipment for multi-layer polyester fiber pad

A technology of thermocompression bonding and polyester fiber, applied in the field of thermocompression bonding equipment for multi-layer polyester fiber pads, can solve the problems of changing the matching speed, speeding up the moving speed of the pressure plate, affecting the normal cooperation between the pressure plate and the hydraulic rod, etc. The effect of speeding up the flow rate, reducing liquefaction on the inner wall of the exhaust hole, and maintaining smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 To attach Figure 5 Shown:

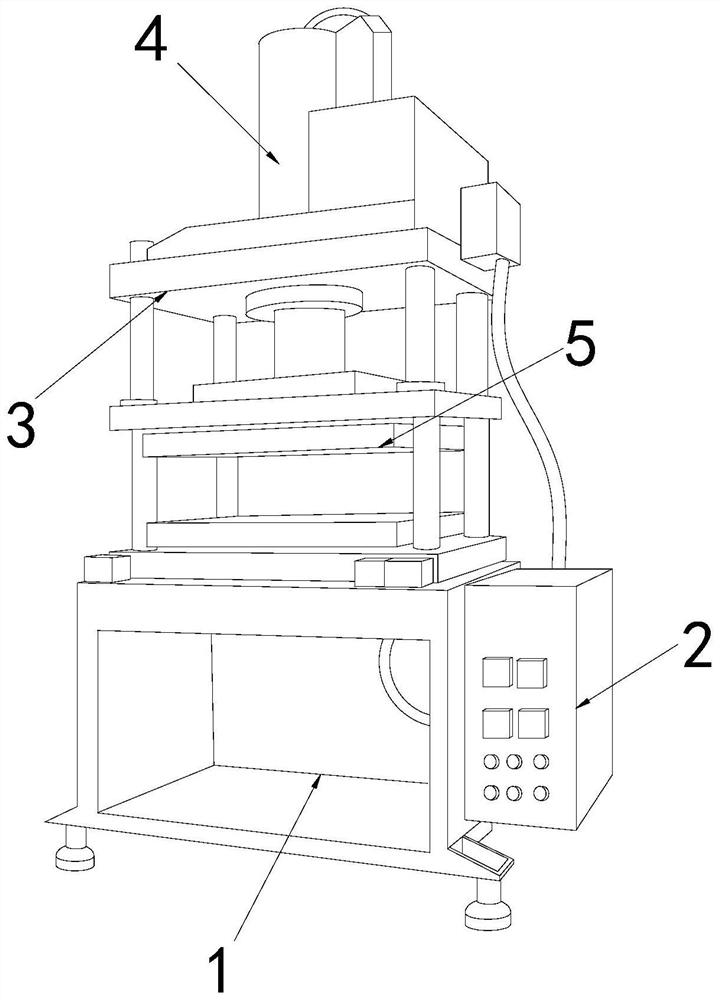

[0028] The invention provides a multi-layer polyester fiber mat thermocompression bonding equipment, the structure of which includes a body 1, a control box 2, a top seat 3, a hydraulic cylinder 4, and a thermocompression mechanism 5, and the control box 2 is installed on the right side of the body 1. On the side, the top seat 3 is vertically arranged above the body 1, the hydraulic cylinder 4 is installed on the top surface of the top seat 3, and the hot-pressing mechanism 5 is clamped between the top seat 3 and the top of the body 1.

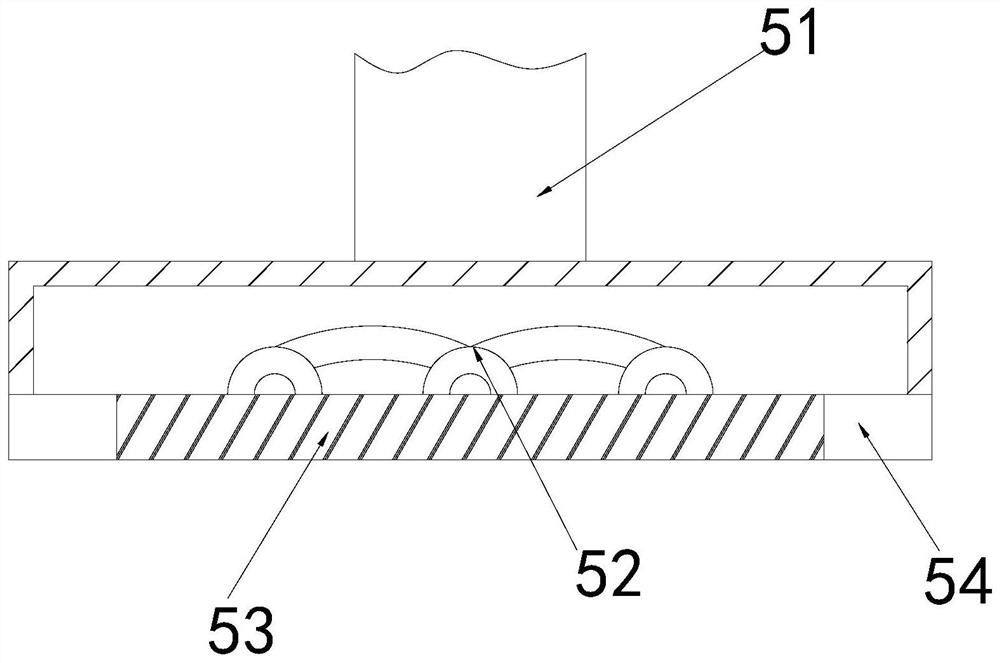

[0029] The hot pressing mechanism 5 is provided with a hydraulic rod 51, a heater 52, a pressing plate 53, and a buffer device 54. The hydraulic rod 51 is vertically installed at the center of the top of the hot pressing mechanism 5, and the heater 52 is located inside the hot pressing mechanism 5. , the pressing plate 53 is fixed horizontally in the middle of the bottom surface of the...

Embodiment 2

[0036] as attached Image 6 To attach Figure 8 Shown:

[0037] Wherein, the exhaust hole a6 is provided with a block e1, a tie bar e2, and a cleaning device e3, the block e1 is embedded in the top of the vent hole a6, and the tie bar e2 is connected to the bottom surface of the block e1, The clearing device e3 is arranged inside the exhaust hole a6, and is movably coordinated with the stay bar e2. The stay bar e2 is provided with two pieces, which are located on the upper surfaces of both ends of the top of the clearing device e3, which is conducive to the even force of the clearing device e3. Maintain a horizontal angle while moving.

[0038]Wherein, the removal device e3 is provided with a telescopic tube r1 and a contact block r2, the telescopic tube r1 is located in the middle of the removal device e3, the contact block r2 is fixed at both ends of the telescopic tube r1, and the telescopic tube r1 is made of rubber material, It is elastic, which is beneficial for defor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com