Fresh vegetable and fruit pushing-cutting and strip-forming equipment for animal husbandry

A technology for animal husbandry and vegetables, which is applied in the field of pushing and cutting equipment for fresh vegetables and fruits in animal husbandry, which can solve the problems of low work efficiency and people's fatigue, and achieve the effect of saving cutting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

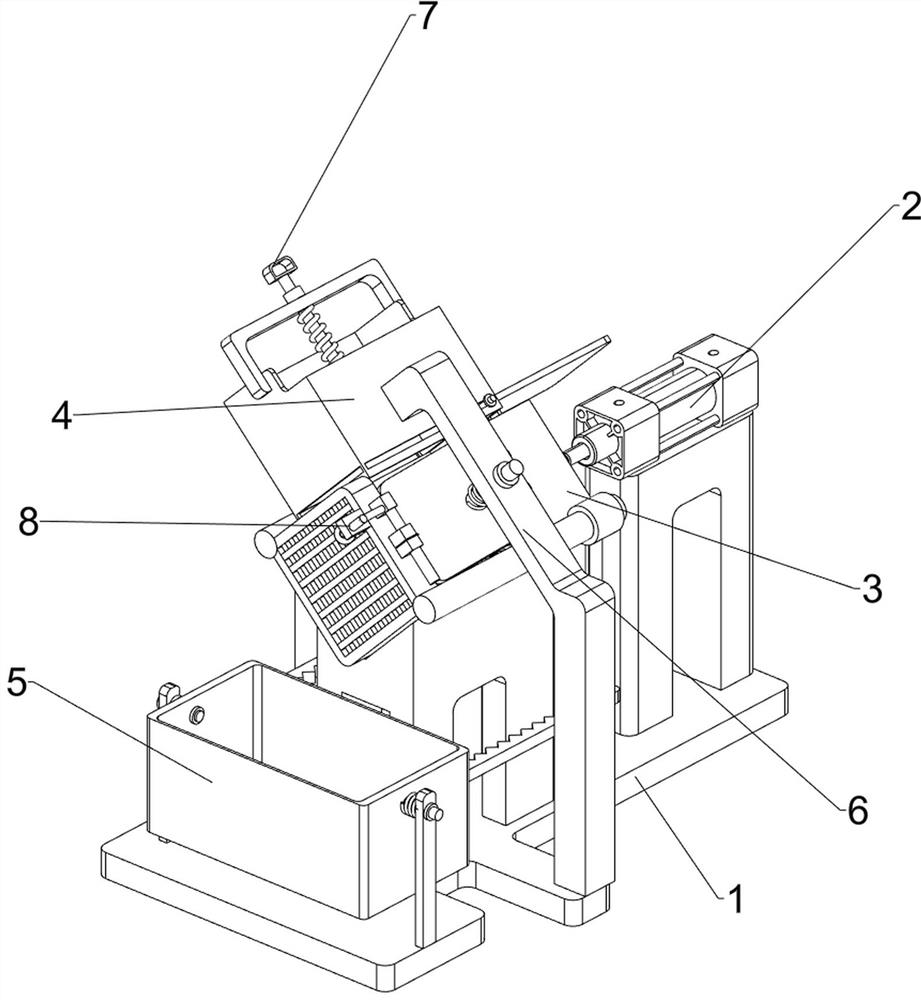

[0062] A kind of equipment for pushing and cutting fresh vegetables and fruits in animal husbandry, such as Figure 1-2 As shown, it includes a bottom plate 1, a cylinder 2, a push-cut mechanism 3 and a blanking mechanism 4, a cylinder 2 is connected to the rear side of the top of the bottom plate 1, a push-cut mechanism 3 is connected between the bottom plate 1 and the cylinder 2, and a push-cut mechanism 3 is connected to the bottom plate 1. Feeding mechanism 4.

[0063] When people need to cut vegetables and fresh fruits, they first place the fresh fruits and vegetables in the unloading mechanism 4, so that the fresh fruits and vegetables fall into the pushing and cutting mechanism 3, and then control the extension of the cylinder 2, so that the pushing and cutting mechanism 3 cuts the fresh fruits and vegetables into strips. The strip cutting can be completed, and then the cylinder 2 can be controlled to shorten.

Embodiment 2

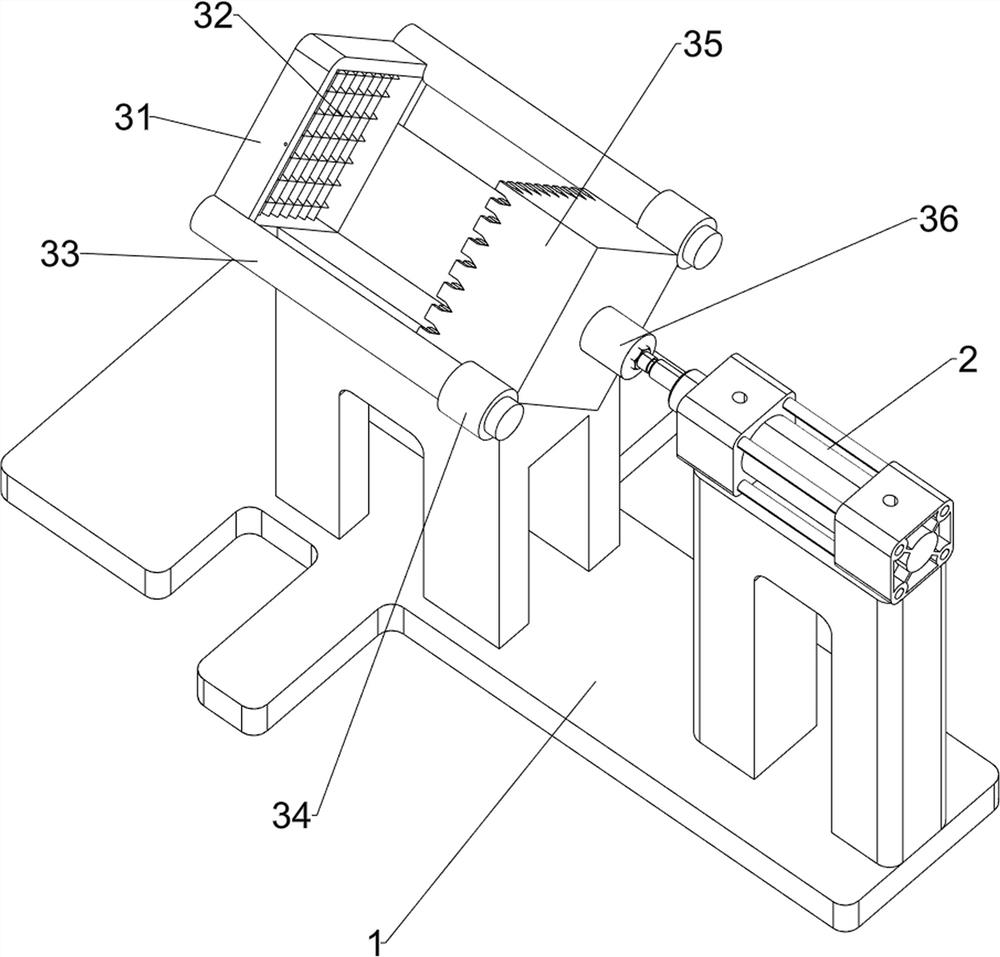

[0065] On the basis of Example 1, such as Figure 3-4 As shown, the pushing and cutting mechanism 3 includes a first fixed frame 31, a cutting tool 32, a first fixed rod 33, a sliding sleeve 34, a pushing block 35 and a connecting block 36, and the front side of the top of the bottom plate 1 is connected with the first fixed frame 31. , the first fixed frame 31 front side is connected with a cutting tool 32, the first fixed frame 31 left and right sides are connected with a first fixed rod 33, the first fixed rod 33 is slidably connected with a sliding sleeve 34, the sliding sleeve 34 A pusher block 35 is arranged between them, and a connection block 36 is connected to the rear side of the pusher block 35, and the connection block 36 is connected with the cylinder 2.

[0066]After the fresh fruits and vegetables fall into the first fixed frame 31, the extension of the cylinder 2 drives the connecting block 36, the sliding sleeve 34 and the pushing block 35 to move forward, so ...

Embodiment 3

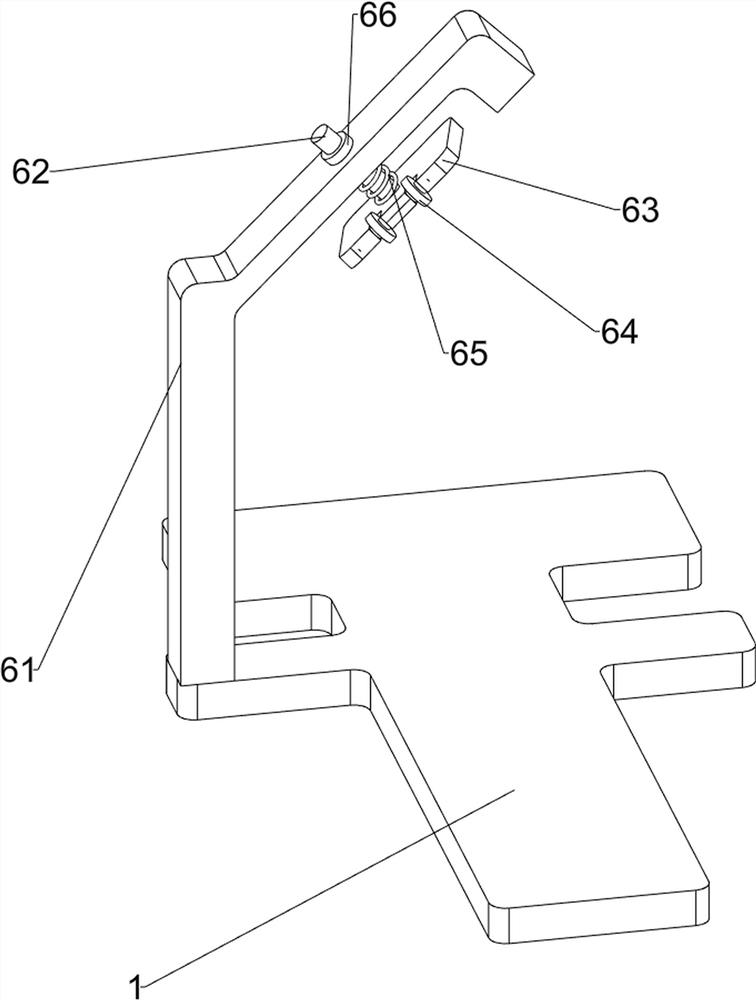

[0070] On the basis of Example 2, such as Figure 5-8 Shown, also include shaker mechanism 5, shaker mechanism 5 includes fixed plate 51, second fixed rod 52, collection box 53, first spring 54, tooth bar 55 and driving lever 56, bottom plate 1 front portion left and right sides The sides are connected with a fixed plate 51, and the fixed plate 51 is slidably connected with a second fixed rod 52, and a collection box 53 is connected between the second fixed rods 52, and the left and right sides of the collection box 53 are connected with the fixed plate 51 on the same side. The first spring 54 is connected between them, the first spring 54 is set on the outside of the second fixed rod 52, the left and right sides of the rear part of the collection box 53 are connected with racks 55, the bottom of the sliding sleeve 34 is connected with a driving rod 56, and the driving rod 56 meshes with the rack 55 on the same side.

[0071] When the sliding sleeve 34 moves back and forth, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com