Full-automatic metal plate cutting device

A cutting device, metal plate technology, applied in metal sawing equipment, sawing machine equipment, metal processing equipment and other directions, can solve the problems of inability to achieve fully automatic cutting, increase cutting time, reduce cutting efficiency, etc., to facilitate transmission, reduce Cutting time, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

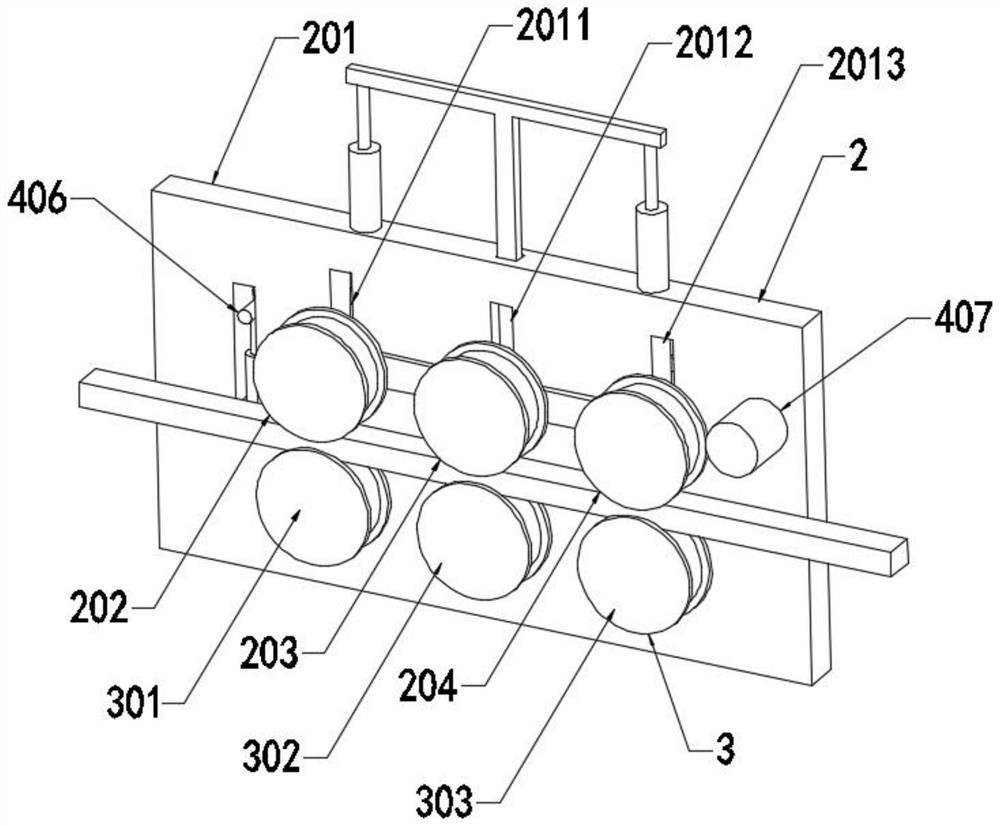

[0039] see Figure 1-8 , the present invention provides a technical solution: a fully automatic metal plate cutting device, including a workbench 1, a moving roller conveying assembly 2, a static roller conveying assembly 3, a transmission assembly 4, a cutting assembly 5, a fixing assembly 6, and a transport assembly 7 and collection component 8;

[0040] The moving roller conveying assembly 2 includes a riser 201, the riser 201 is fixedly installed on the workbench 1, the riser 201 is provided with a first groove 2011, a second groove 2012 and a third groove 2013, the first groove 2011 The first rotating shaft 206 is installed in rotation, the second rotating shaft 207 is installed rotating in the second groove 2012, the third rotating shaft 208 is installed rotating in the third groove 2013, and the first moving roller 202 is fixedly installed on one end of the first rotating shaft 206 , one end of the second shaft 207 is fixedly mounted with the second moving roller 203, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com