Butterfly plate combination method of butterfly valve assembling machine

A technology of butterfly valve and combination method, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of increasing manufacturing cost, storage management cost, and reducing production efficiency, so as to reduce production cost and storage management cost, Improve the processing applicability and the effect of firm limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

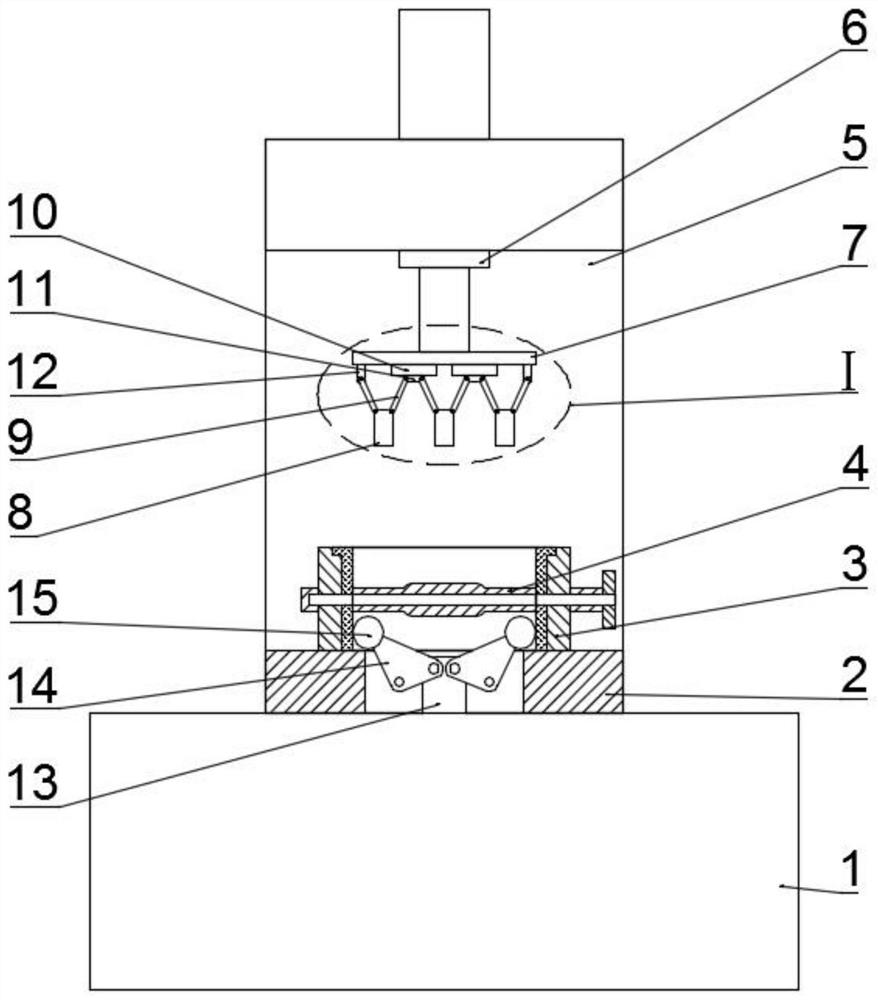

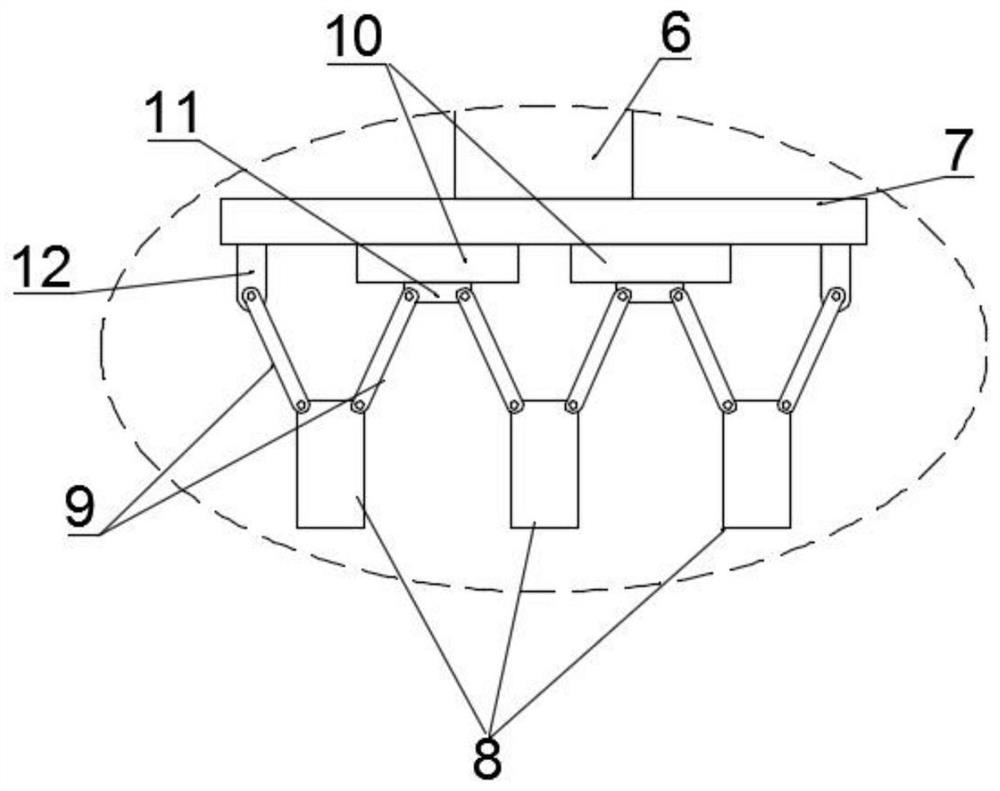

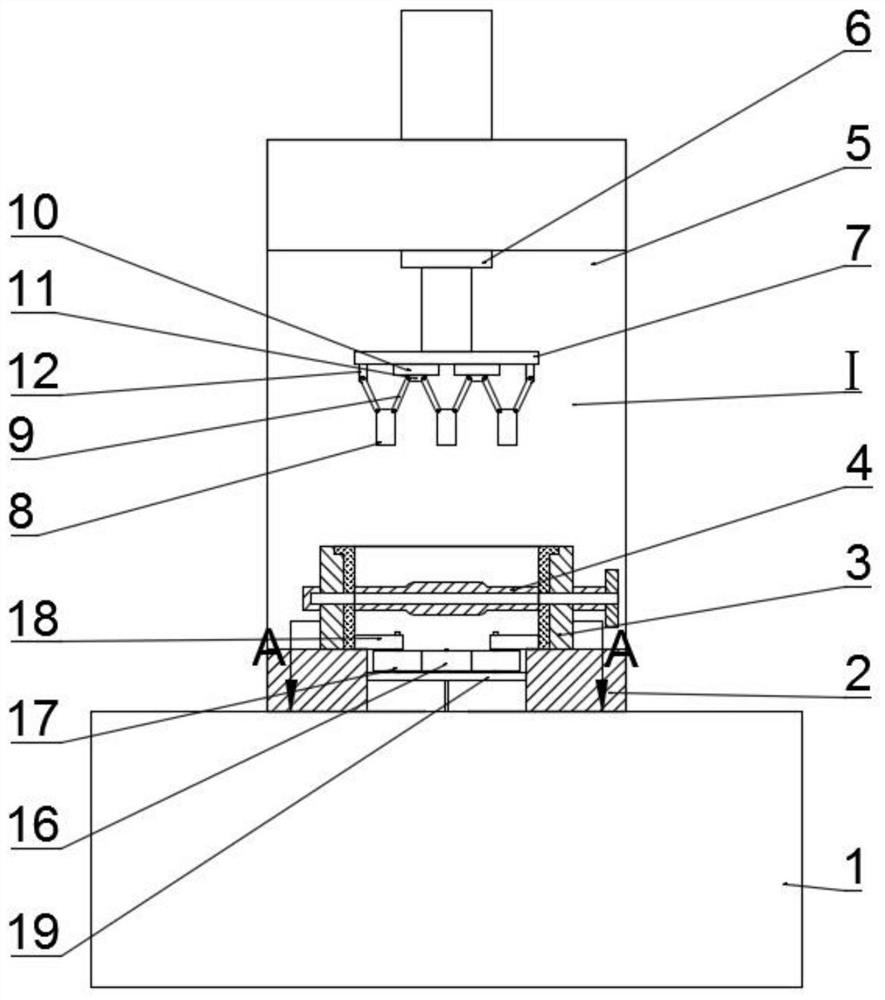

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] Such as Figure 1-7 As shown, a butterfly plate assembly method of a butterfly valve assembly machine includes the following steps:

[0032] Step 1. First place the valve body 3 on the processing table 2 for positioning, and then place the butterfly plate 4 on the upper side of the opening of the valve body 3;

[0033] Step 2, start the lifting drive mechanism, the lower movable end of the lifting drive mechanism moves down with the lifting plate 7, and also moves down with the briquetting block 8 during the downward movement of the lifting plate 7, one or several briquetting blocks 8 First contact with the protrusion on the upper surface of the butterfly plate 4;

[0034]Step 3: The pressure block that first contacts the protrusion on the upper surface of the butterfly plate 4 stops moving down temporarily due to resistance, while ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com