Butterfly plate combination device of butterfly valve assembling machine

A combined device and butterfly valve technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing production efficiency, increasing manufacturing costs and storage management costs, improving processing applicability and reducing production costs. and storage management costs, the effect of ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

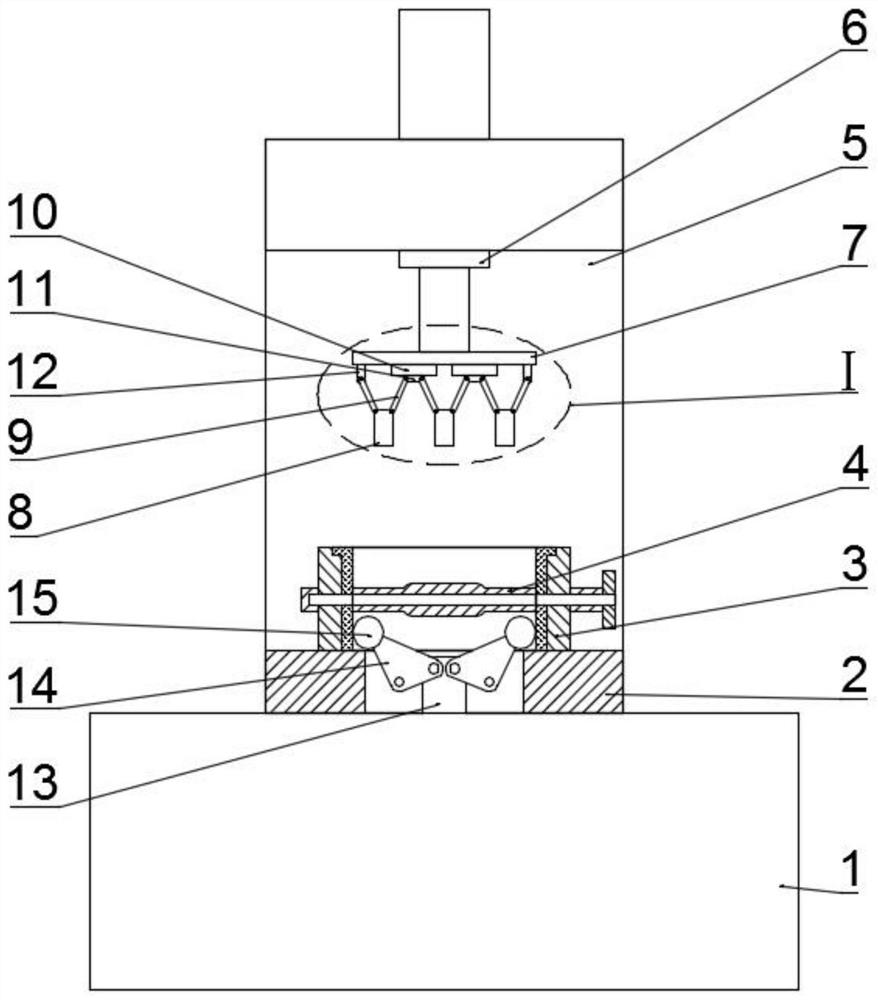

[0028] Such as figure 1 and 2 As shown, a butterfly plate combination device of a butterfly valve assembly machine includes a machine platform 1, a processing platform 2 installed on the machine platform 1 and used for placing the valve body 3, and a vertical plate 5 fixedly arranged on the machine platform 1 The upper part of the processing table 2 is provided with a lifting plate 7, the two ends of the lower surface of the lifting plate 7 are fixedly provided with connecting plates 12, and the middle of the lower surface of the lifting plate 7 is fixedly provided with at least two slide rails 10. The slide rail 10 is provided with a slider 11 that can move along the slide rail 10 with a single degree of freedom, and the connecting plate 12 and the slide rail 10 are located on the same straight line, and a connecting plate 12 is hinged Rod 9, two connecting rods 9 are hinged on the slider 11, a pressing block 8 is arranged below between two adjacent connecting rods 9, and th...

Embodiment 2

[0034] Such as image 3 and 4 As shown, a butterfly plate combination device of a butterfly valve assembly machine includes a machine platform 1, a processing platform 2 installed on the machine platform 1 and used for placing the valve body 3, and a vertical plate 5 fixedly arranged on the machine platform 1 The upper part of the processing table 2 is provided with a lifting plate 7, the two ends of the lower surface of the lifting plate 7 are fixedly provided with connecting plates 12, and the middle of the lower surface of the lifting plate 7 is fixedly provided with at least two slide rails 10. The slide rail 10 is provided with a slider 11 that can move along the slide rail 10 with a single degree of freedom, and the connecting plate 12 and the slide rail 10 are located on the same straight line, and a connecting plate 12 is hinged Rod 9, two connecting rods 9 are hinged on the slider 11, a pressing block 8 is arranged below between two adjacent connecting rods 9, and th...

Embodiment 3

[0040] Such as Figure 5-7 As shown, a butterfly plate combination device of a butterfly valve assembly machine includes a machine platform 1, a processing platform 2 installed on the machine platform 1 and used for placing the valve body 3, and a vertical plate 5 fixedly arranged on the machine platform 1 The upper part of the processing table 2 is provided with a lifting plate 7, the two ends of the lower surface of the lifting plate 7 are fixedly provided with connecting plates 12, and the middle of the lower surface of the lifting plate 7 is fixedly provided with at least two slide rails 10. The slide rail 10 is provided with a slider 11 that can move along the slide rail 10 with a single degree of freedom, and the connecting plate 12 and the slide rail 10 are located on the same straight line, and a connecting plate 12 is hinged Rod 9, two connecting rods 9 are hinged on the slider 11, a pressing block 8 is arranged below between two adjacent connecting rods 9, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com