A kind of light-emitting sheet production equipment and its production process

A technology for producing equipment and light-emitting sheets, applied in welding equipment, metal processing equipment, metal processing and other directions, can solve the problems of low solder drying efficiency, and achieve the effects of shortening drying time, improving service life and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

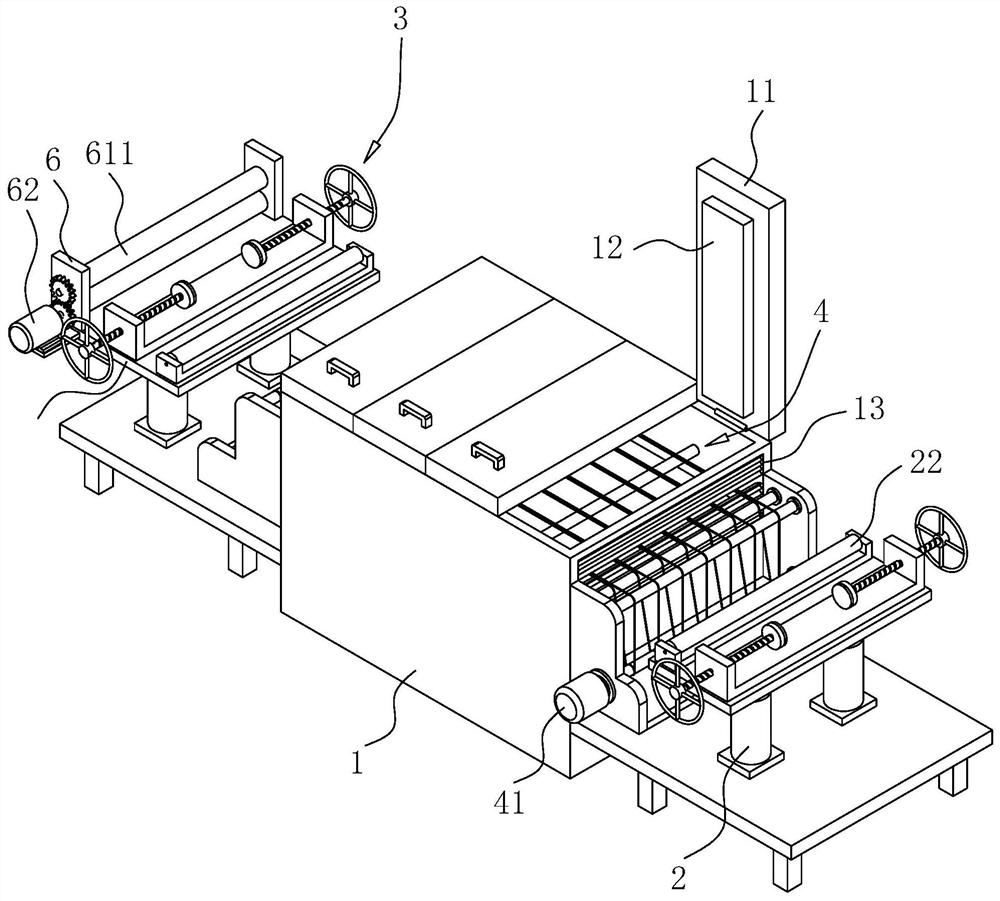

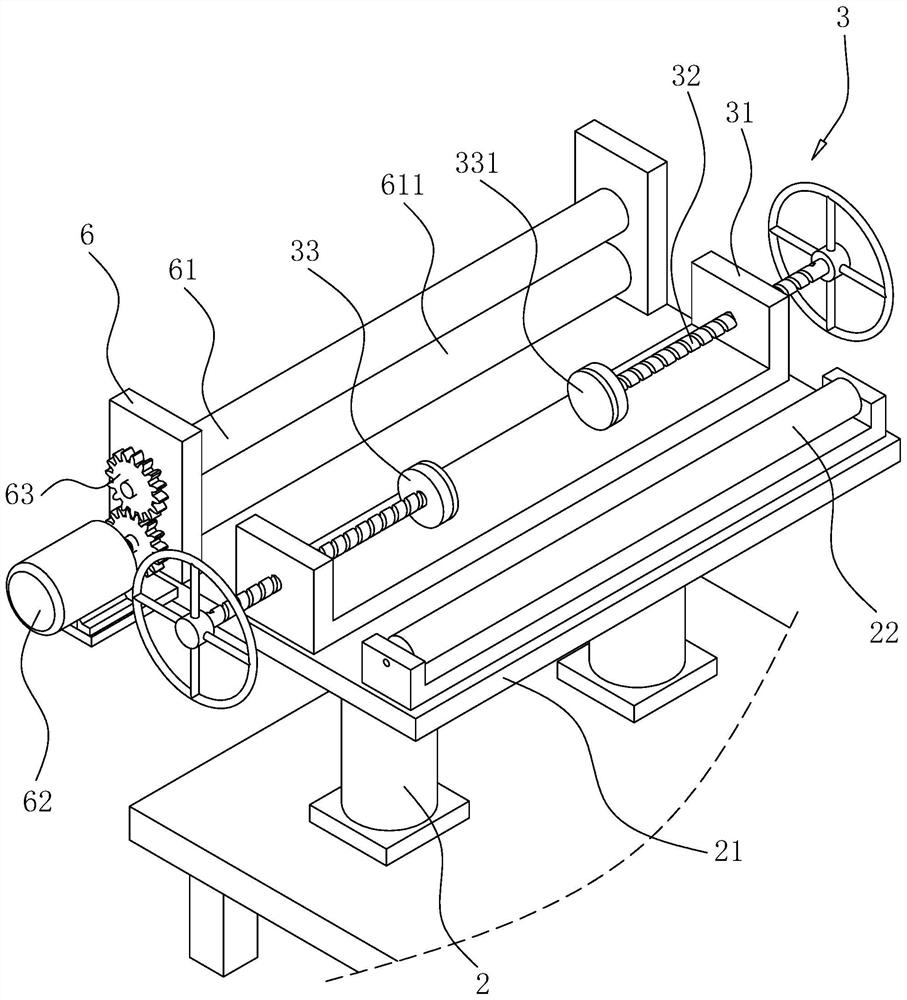

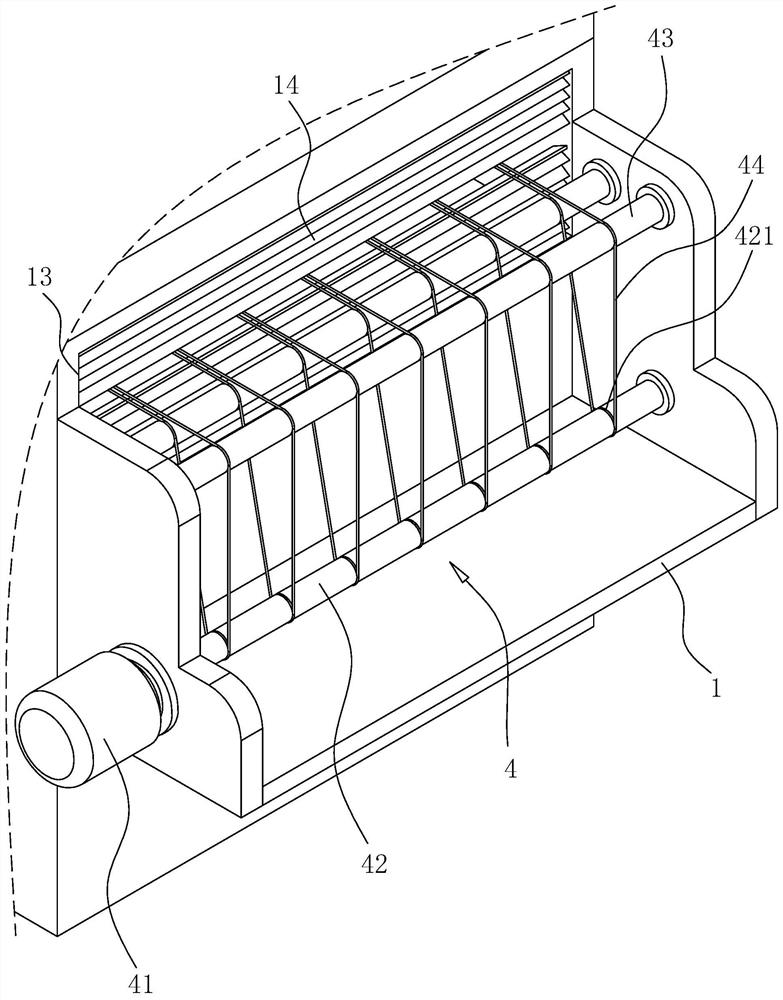

[0041] Attached to the following Figure 1-4 This application will be described in further detail.

[0042] The embodiment of the present application discloses a device for producing a light-emitting sheet.

[0043] refer to figure 1 , a light-emitting sheet production equipment comprises a body 1 with an upper opening, a plurality of mutually abutting cover 11 are hinged on the upper surface of the body 1, the interior of the cover 11 is connected to a closed cavity, and the inner bottom wall of the cover 11 is fixed with heating For the plate 12, the travel direction of the plate and the arrangement direction of the cover 11 are parallel to the length direction of the body 1. Both ends of the body 1 are provided with through holes 13 for the soldered plate to enter and leave the lower part of the cover 11, Both ends of the body 1 in the length direction are provided with lifting components for lifting the board, and the height of the through hole 13 is not lower than the lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com