A deformation control method for additive manufacturing of thin-walled partition parts

A technology of additive manufacturing and deformation control, applied in additive manufacturing, additive processing, etc., can solve problems such as deformation of thin-walled isolation parts, achieve the effects of improving surface quality, reducing deformation, and increasing bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

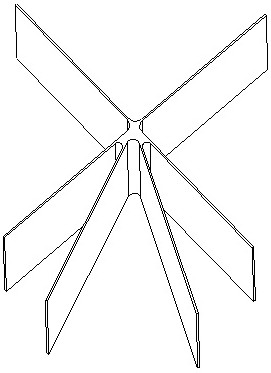

[0040] The three-dimensional digital model of the thin-walled partition parts involved in this embodiment is as follows figure 1 As shown, the material is aluminum alloy, and the forming method is SLM additive manufacturing. After analysis, the size of the part is 220×200×80mm, the thickness of the thin-walled partition is 1mm, and the length of the thin-walled partition is about 100mm. It belongs to a V-shaped part. During the forming process of the thin-walled structure, it is easy to deform and the knife gets stuck, which makes it difficult to form the part. .

[0041] Using the deformation control method for additive manufacturing of thin-walled partition parts of the present application, the steps are as follows:

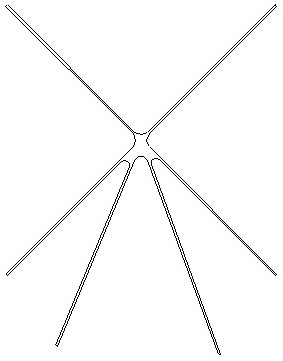

[0042] S1. Determine the placement of the parts, and determine the growth direction of the parts to be parallel to each thin-walled partition. The 2D profile of a single-layer sintered part as figure 2 As shown, there is no constraint on the position of the...

Embodiment 2

[0047] The three-dimensional digital model of the thin-walled partition parts involved in this embodiment is as follows Figure 5 As shown, the material is titanium alloy, and the forming method is SLM additive manufacturing. After analysis, the size of the part is 300×300×50mm, the thickness of the thin-walled blade is 2mm, and the length of the thin-walled blade is about 130mm. It belongs to a V-shaped part. The stress in the forming process of titanium alloy is large, and the thin-walled structure is easy to deform and jam during the forming process. , making the parts difficult to shape.

[0048] Using the deformation control method for additive manufacturing of thin-walled partition parts of the present application, the steps are as follows:

[0049] S1. Determine the placement of the parts, and determine the growth direction of the parts to be parallel to each thin-walled partition. The 2D profile of a single-layer sintered part as Figure 6 As shown, there is no cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com