96-slot stator assembly and motor with same

A slot stator and assembly technology, which is applied in the field of 96-slot stator assemblies and motors with its structure, can solve the problem of large distance between star point lead-out lines and three-phase lead-out lines, complex structure of center lines and three-phase copper bars, etc. Complex production process and other problems, to achieve the effect of simple welding and coating process, convenient processing and assembly, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

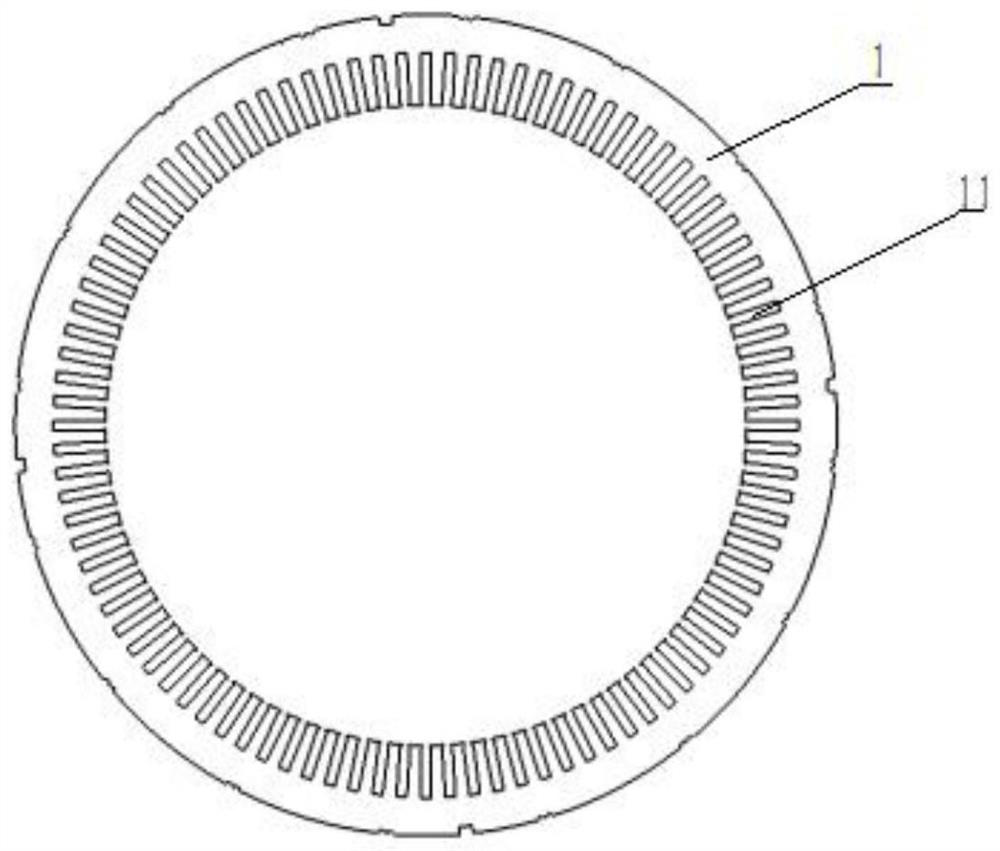

[0036] like figure 1 As shown, a 96-slot stator assembly, including the stator core, such as image 3 As shown, the stator core 1 is cylindrical, and the stator core is provided with 96 stator slots 11 arranged at intervals along the circumferential direction of the stator core and a stator winding 2 composed of a plurality of conductor segments. The stator slots 11 are formed in on the inner wall of the stator core 1 and penetrates the stator core 1 in the axial direction, and the depth direction of the stator slot is consistent with the radial direction of the stator core 1 .

[0037] In the stator slot, several layers of conductor segments are radially distributed along the stator core (the number of layers of the conductor segment is an even-numbered layer not less than 6 layers). There are a first end and a second end extending to the outside of the stator core, a plurality of first ends form the winding hairpin end 21, the second end forms the winding twist welding end ...

Embodiment 2

[0057] like figure 1 As shown, a 96-slot stator assembly, including the stator core, such as image 3 As shown, the stator core 1 is cylindrical. The stator core is provided with 96 stator slots arranged at intervals along the circumferential direction of the stator core and a stator winding composed of a plurality of conductor segments. The stator slots are formed on the stator core. 1, and penetrates the stator core 1 in the axial direction, and the depth direction of the stator slot is consistent with the radial direction of the stator core 1.

[0058] In the stator slot, several layers of conductor segments are radially distributed along the stator core (the number of layers of the conductor segment is an even-numbered layer not less than 6 layers). There are a first end and a second end extending to the outside of the stator core, a plurality of first ends form a winding hairpin end 21, a second end forms a winding twist welding end 22 and a winding lead wire welding end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com