Porous current collector and preparation method thereof, lithium negative electrode and lithium ion battery

A technology of porous current collector and porous skeleton, which is applied in the field of lithium ion battery, porous current collector and its preparation, and lithium negative electrode. It can solve the problem of low lithium affinity of porous skeleton, reduce the generation probability, and reduce the nucleation overpotential , Improve the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Another embodiment of the present invention provides a method for preparing a porous current collector as described above, comprising the following steps:

[0049] Electroplating: the conductive porous skeleton is placed in a copper salt solution, the conductive porous skeleton is used as the cathode for electroplating, and a copper layer is formed on the surface of the conductive porous skeleton and the inner wall of the micropore;

[0050] Heat treatment: Heat treatment is performed on the conductive porous skeleton to oxidize the copper layer to copper oxide.

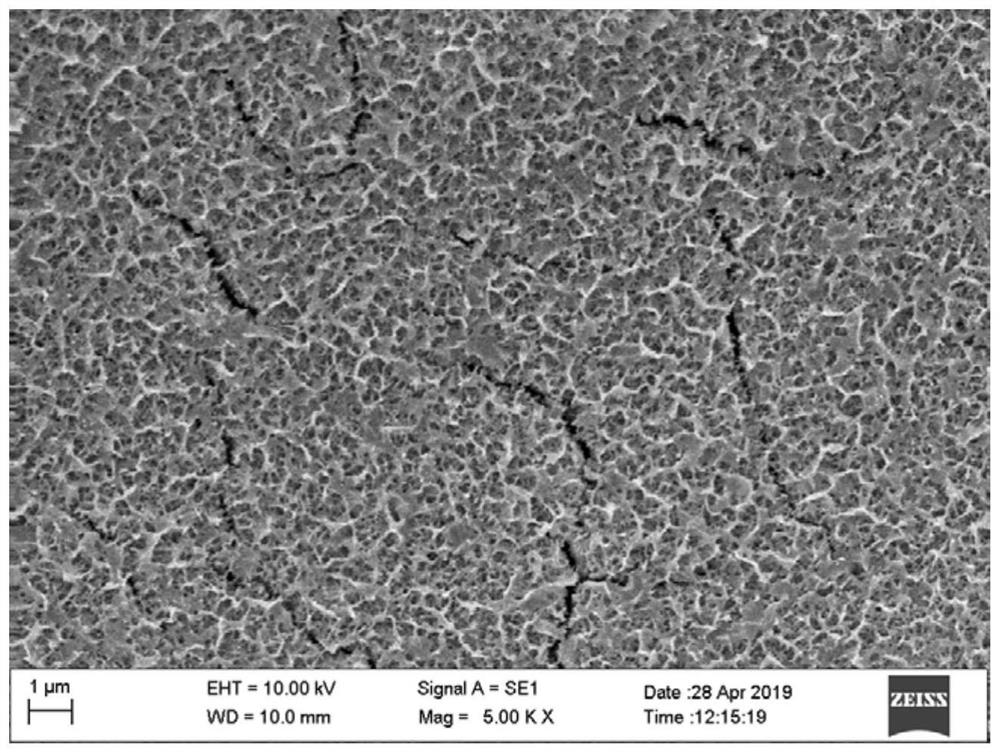

[0051] In this embodiment, a copper layer is formed on the inner and outer surfaces of the conductive porous skeleton by electroplating. Compared with vapor deposition, plasma deposition, etc., the electroplating method can ensure the uniformity of the copper layer on the conductive porous skeleton, thereby The inner wall of the micropores of the conductive porous skeleton is also attached with a copper layer....

Embodiment 1

[0074] This example is used to illustrate the porous current collector disclosed in the present invention and its preparation method, including the following steps:

[0075] 1) Pretreatment of conductive porous framework.

[0076] Select foamed nickel with appropriate specifications as the conductive porous framework, with a pore volume of 75%, a pore diameter of 300 μm, and a thickness of 0.3 mm. Soak the nickel foam in 0.5 mol / L hydrochloric acid for 30 minutes, then ultrasonically clean the copper foam with acetone twice for 20 minutes, and finally dry the nickel foam in vacuum at a drying temperature of 60°C for 4 hours.

[0077] 2) The surface is copper-plated.

[0078] The electroplating solution is 0.1mol / LCuSO 4 , 0.5mol / LH 2 SO 4 mixed aqueous solution. The titanium-platinum mesh is used as the anode, and the conductive porous skeleton in step 1) is used as the cathode, and the two poles are respectively connected to the power supply, placed in the electroplating...

Embodiment 2

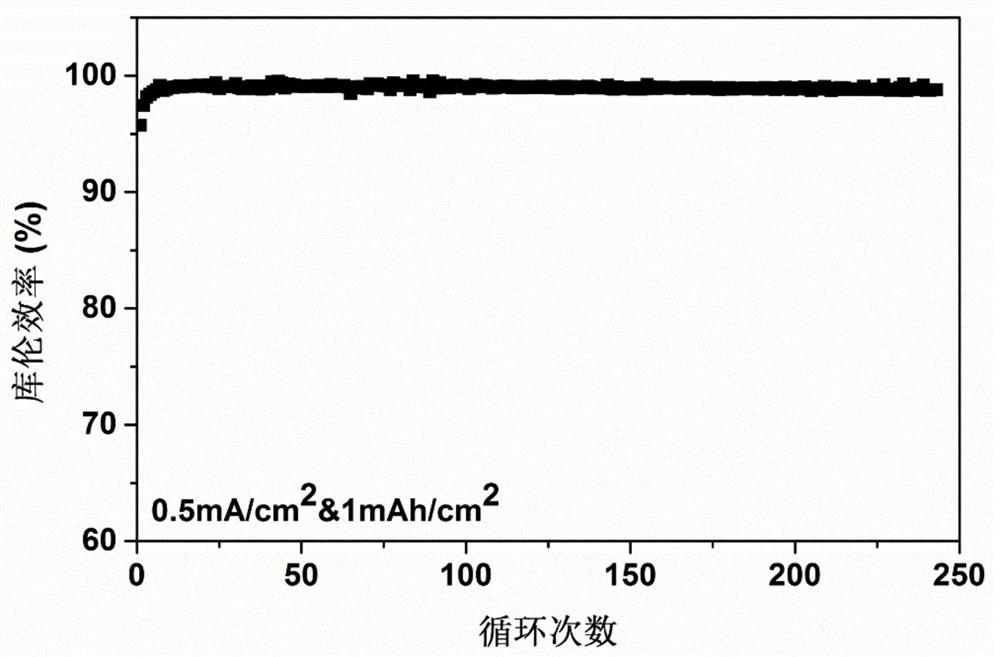

[0084] This example is used to illustrate the porous current collector, lithium negative electrode and preparation method thereof disclosed in the present invention, including the following steps:

[0085] 1) Pretreatment of conductive porous framework.

[0086] Select foamed nickel with appropriate specifications as the conductive porous framework, with a pore volume of 75%, a pore diameter of 300 μm, and a thickness of 0.3 mm. Soak the nickel foam in 0.5mol / L hydrochloric acid for 30 minutes, then ultrasonically clean the nickel foam with acetone twice for 20 minutes, and finally dry the nickel foam in vacuum at a drying temperature of 60°C for 4 hours.

[0087] 2) The surface is copper-plated.

[0088] The electroplating solution is 0.1mol / LCuSO 4 , 0.5mol / LH 2 SO 4mixed aqueous solution. The titanium-platinum mesh is used as the anode, and the conductive porous skeleton in step 1) is used as the cathode, and the two poles are respectively connected to the power supply...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com