Bar-shaped solar battery piece, solar battery, photovoltaic module and manufacturing method thereof

A technology for solar cells and photovoltaic modules, applied in the fields of photovoltaic power generation, electrical components, and final product manufacturing, can solve the problem of limited power generation of photovoltaic modules, and achieve the effect of eliminating the gap between the sheets and reducing the split rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

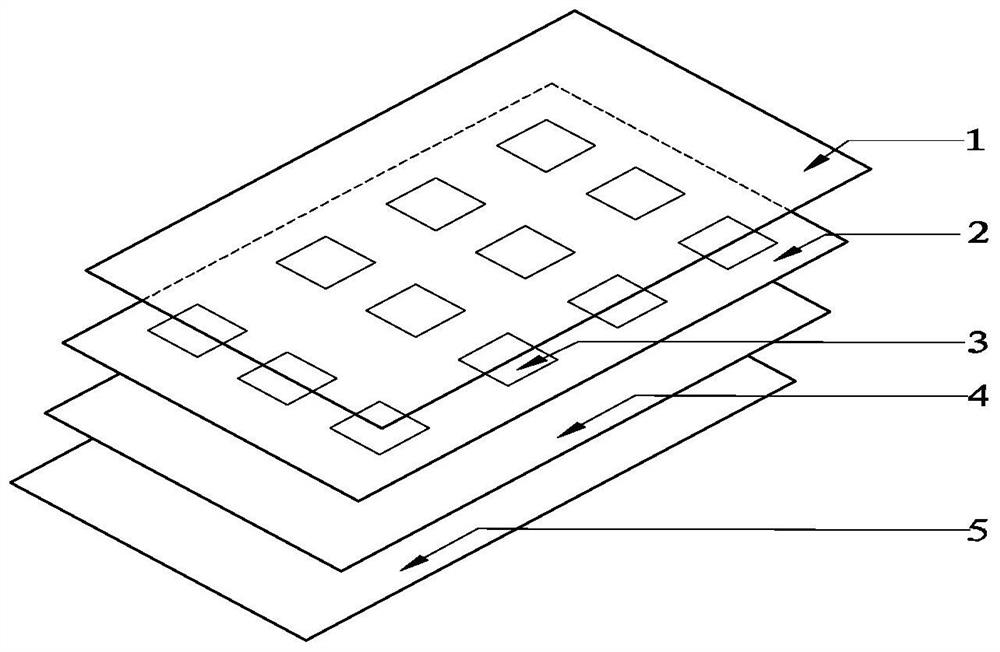

[0055] Such as figure 1 As shown, a photovoltaic module generally includes a five-layer structure, from top to bottom: a light-transmitting front plate (such as glass) 1, an encapsulating film 2, a solar cell 3, an encapsulating film 4, and a back plate (such as glass) 5. After the five-layer structure is vacuumized, heated, and laminated, the encapsulation film 2 and 4 are cross-linked and cured, so that the five-layer structure is firmly bonded together, and the aluminum frame and junction box are added and sealed with silica gel. After that, a conventional photovoltaic module is produced. The solar cell 3 can be a monocrystalline silicon cell or a polycrystalline silicon cell, and two adjacent solar cells 3 are electrically connected by a wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com