Low-temperature composite gas cylinder design method

A composite material and design method technology, applied in the field of low-temperature pressure vessels, can solve the problems of unsatisfactory gas cylinder performance, incompleteness, complex design, etc., and achieve the effects of high design efficiency, rapid design, and comprehensive design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

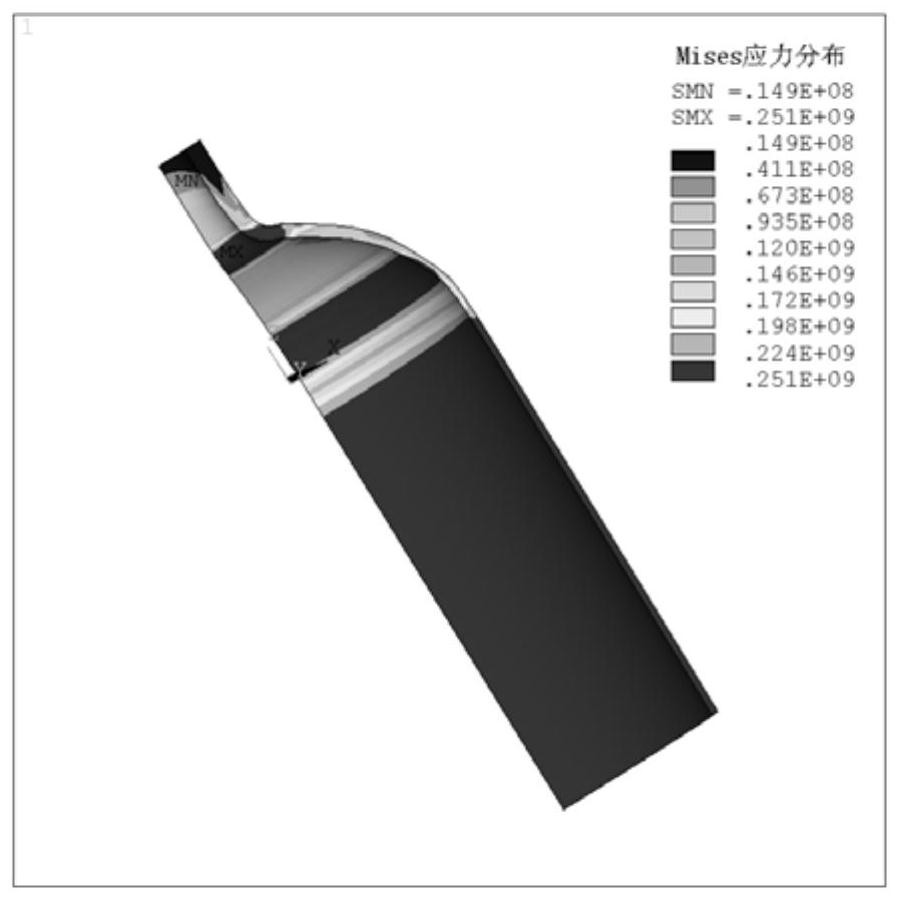

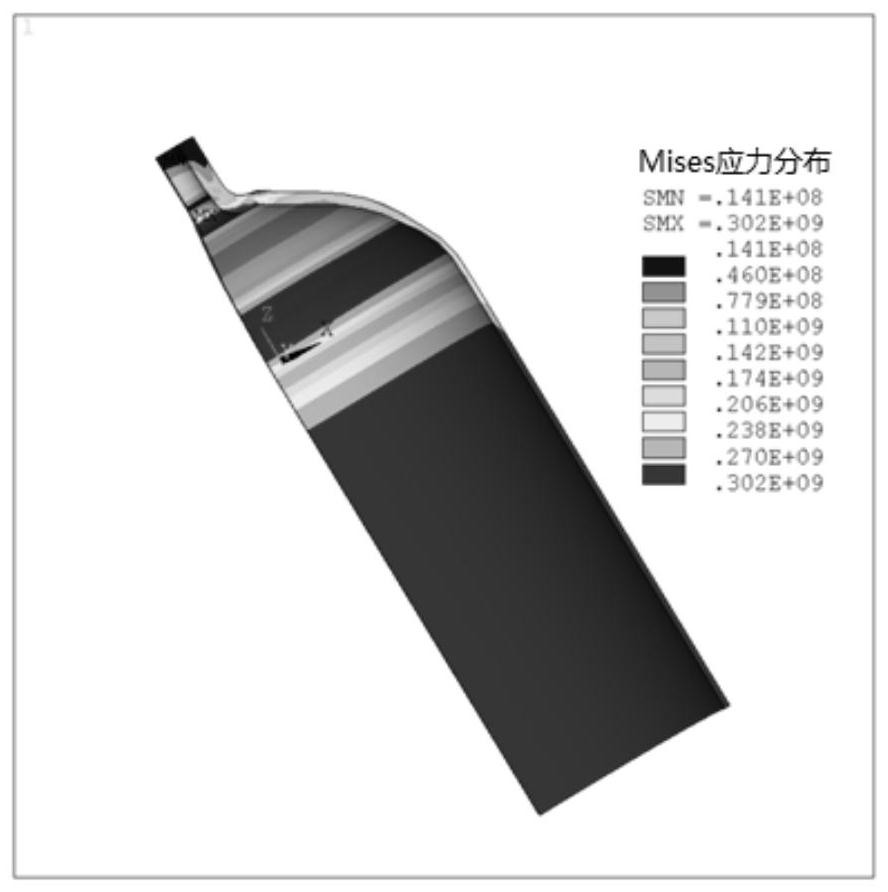

[0080] A low-temperature composite gas cylinder with a volume of 25L requires normal temperature working pressure of 23MPa, 77K~93K working pressure of 23MPa, normal temperature burst pressure of 46MPa, and low temperature burst pressure of 46MPa. The inner diameter of the gas cylinder is 242mm, and the head is ellipsoidal. The cylinder lining is 6061 aluminum alloy.

[0081] Normal temperature tensile strength σ of composite fiber direction c1 =2200MPa, 77K~93K low temperature tensile strength σ d1 =1760MPa, normal temperature tensile modulus E c1 =140GPa, 77K~93K low temperature tensile modulus E d1 =154GPa; the normal temperature tensile strength σ of the composite material perpendicular to the fiber direction c2 =40MPa, 77K~93K low temperature tensile strength σ d2 =48MPa, normal temperature tensile modulus E c2 =7GPa, 77K~93K low temperature tensile modulus E d2 =8.4GPa; composite fiber direction linear expansion coefficient α 1 =1×10 -7 / K, linear expansion coef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com