High-precision four-wire type wire rod tester and testing method thereof

A technology of a wire tester and a test method, which is applied in the direction of short-circuit test, continuity test, and parts of electrical measuring instruments, etc., and can solve problems such as wire damage, wrong pulling and dropping of the tester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

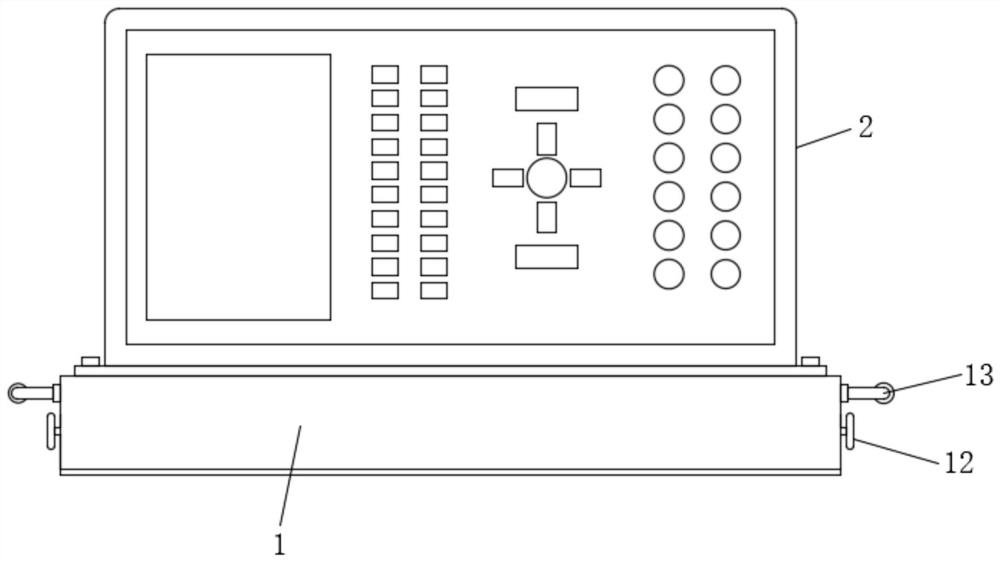

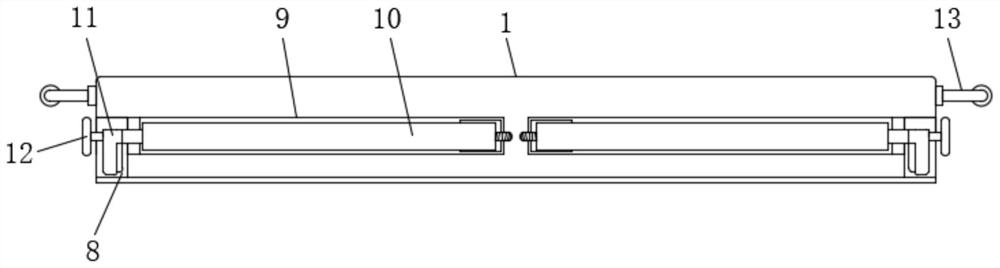

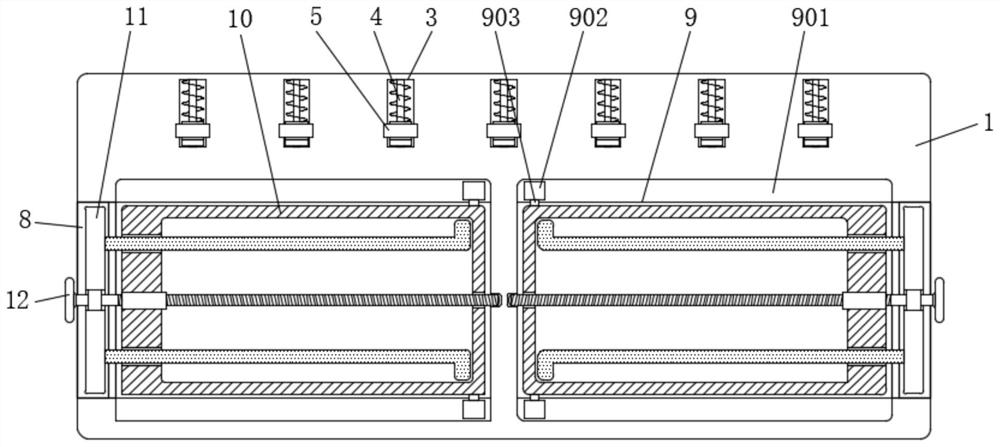

[0033]Example 1Figure 1 to 6It is given, the present invention includes a base 1, and the top of the base 1 is mounted having a tester body 2, one side of the top of the base 1 is equipped with a moving groove 3, and the internal mounting of the moving groove 3 is mounted with a buffer mechanism 4, the buffer mechanism 4 The top is mounted with vertical block 5, and the top of the vertical block 5 is attached to the connection wire fixing mechanism 6, and the tester body 2 is connected to the wire 7, the wire 7 is tensioned at the middle of the connection wire fixing mechanism 6, secured by the connection wire The setting of the mechanism 6 can be effectively tightened and fixed to the wire 7. The lower portion of the base 1 is opened, and the inside of the two card grooves 8 is opened, and the storage chamber 9 is installed. The storage box 10 is provided on one side of the storage cassette 10 and the telescopic frame 11 is attached to the inside of the card groove 8, and the stora...

Embodiment 2

[0034]Embodiment 2. On the basis of the first example,Figure 4 withFigure 6 It is given, the buffer mechanism 4 includes a slider 401, a slider 402, a cushion 403, and a spring 401, and the slider 401 is fixedly mounted inside the moving groove 3, and the slider 402 slides the surface of the slider 401 and sliding the cartridge At the inside of the moving groove 3, the cushion pad 403 is fixed to one side of the slider 402, and the spring 404 is attached to the surface of the slider 401 and is located on the other side of the slider 402, and the vertical block 5 is fixedly mounted on the slider 402. Top, thereby enabling a moving buffer.

Embodiment 3

[0035]Example III, on the basis of an example, byFigure 6 It is given, the connection wire fixing mechanism 6 includes a connecting block 601, a rotating block 602, an elastic hook 603, and a tubular 604, and the connecting block 601 is fixedly mounted on the upper portion of the vertical block 5 side, and one end of the rotating block 602 and the connection block. 601 turning the connection, the elastic hook 603 is fixed to one end of the bottom of the rotary block 602, the snip 604 is fixedly mounted on the other side of the vertical block 5, the elastic hook 603 and the trunk 604 active phase, vertical block 5 The top groove 501 is opened, which can be effectively fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com