Preparation method of durable flame-retardant silk product

A durable flame retardant and silk technology, applied in the direction of flame retardant fibers, textiles, papermaking, fiber processing, etc., can solve the problems of low practical application value, long process flow, complicated operation, etc., to ensure environmental protection, safety, process The effect of short process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

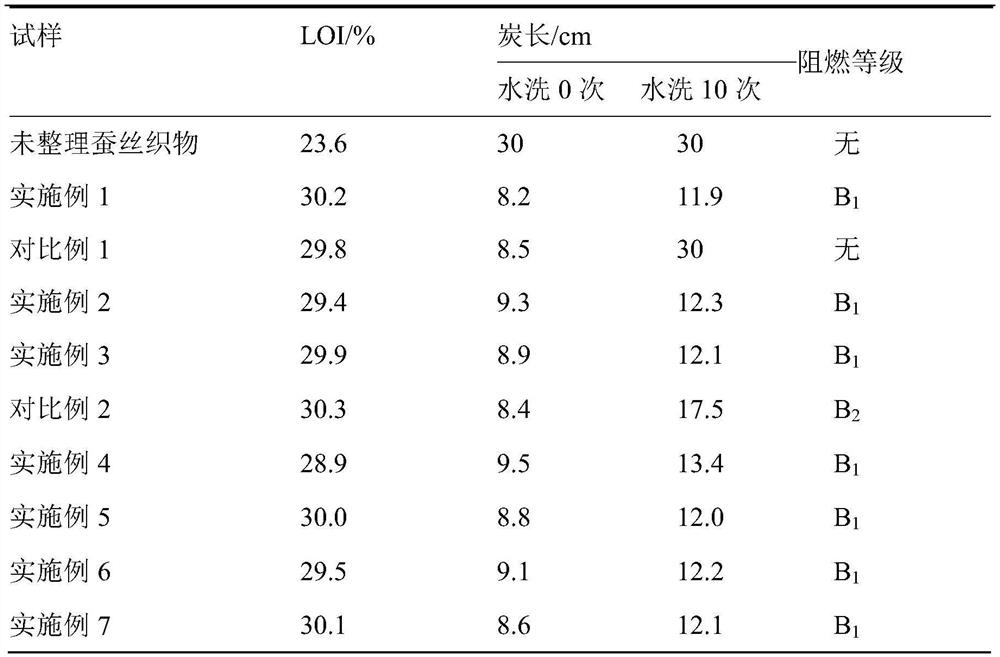

Embodiment 1

[0033] A preparation method of durable flame-retardant silk crepe chine fabric, the specific steps are as follows:

[0034] (1) diethyl phosphite is dissolved in ethanol to obtain diethyl phosphite alcohol solution; the mass volume ratio of diethyl phosphite to ethanol is 13.8g:14mL;

[0035] (2) Diethyl phosphite alcohol solution and glutaraldehyde are dissolved in water, and mixed uniformly to obtain a flame retardant processing fluid; the molar ratio of diethyl phosphite to glutaraldehyde is 4:3; in the flame retardant processing liquid The concentration of diethyl phosphite is 1mol / L;

[0036] (3) Immerse the silk crepe de chine fabric in the flame retardant processing solution, heat it to 80°C, and keep it warm for 60 minutes to obtain durable flame retardant silk crepe de chine; the mass ratio of the silk crepe de chine fabric to the flame retardant processing liquid is 1:50.

Embodiment 2

[0040] A method for preparing a durable flame-retardant silk power textile, the specific steps are as follows:

[0041] (1) diethyl phosphite is dissolved in ethanol to obtain diethyl phosphite alcohol solution; the mass volume ratio of diethyl phosphite to ethanol is 6.9g:7mL;

[0042] (2) Diethyl phosphite alcohol solution and glutaraldehyde are dissolved in water, and mixed evenly to obtain a flame retardant processing fluid; the molar ratio of diethyl phosphite to glutaraldehyde is 1:1; in the flame retardant processing liquid The concentration of diethyl phosphite is 0.5mol / L;

[0043] (3) Immerse the silk power textile in the flame-retardant processing solution, heat it to 70°C, and keep it warm for 80 minutes to obtain a durable flame-retardant silk power textile; the mass ratio of the silk power textile to the flame-retardant processing solution is 1:50.

Embodiment 3

[0045] A method for preparing a durable flame-retardant silk crepe satin fabric, the specific steps are as follows:

[0046] (1) Dimethyl phosphite is dissolved in ethanol to obtain dimethyl phosphite alcohol solution; the mass volume ratio of dimethyl phosphite to ethanol is 8.3g:8mL;

[0047] (2) Dimethyl phosphite alcohol solution and glutaraldehyde are dissolved in water and mixed evenly to obtain a flame retardant processing fluid; the molar ratio of dimethyl phosphite to glutaraldehyde is 15:8; in the flame retardant processing fluid The concentration of dimethyl phosphite is 0.75mol / L;

[0048] (3) Immerse the silk crepe satin fabric in the flame-retardant processing solution, heat it to 90°C, and keep it warm for 40 minutes to obtain a durable flame-retardant silk crepe satin fabric; the mass ratio of the silk crepe satin fabric to the flame-retardant processing solution is 1 :30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com