Ultrahigh-efficiency nano-copper antibacterial agent and preparation method thereof

A technology of nano-copper and antibacterial agent, applied in the field of ultra-efficient nano-copper antibacterial agent and its preparation, can solve the problem that the bactericide cannot withstand repeated washing and the like, and achieve the effects of low cost, simple process and low biological toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A high-efficiency copper nanoparticle liquid antibacterial agent, the ultra-high-efficiency nano-copper antibacterial agent is composed of core-shell copper nanoparticles and phosphate buffer solution, and the concentration of nano-copper is 1 × 10 -7 g / ml, 2×10 -7 g / ml, 3×10 -7 g / ml, 3.5×10 - 7 g / ml, 4×10 -7 g / ml; during preparation, weigh 0.01g, 0.02g, 0.03g, 0.035g, and 0.04g of nano-copper particles, inject 5mL of PBS buffer into the centrifuge tube, add nano-copper powder, and ultrasonically disperse for 10 minutes. Using the dilution method, the final concentration was 1×10 -7 g / ml, 2×10 -7 g / ml, 3×10 -7 g / ml, 3.5×10 -7 g / ml, 4×10 -7 g / ml nano copper antibacterial agent.

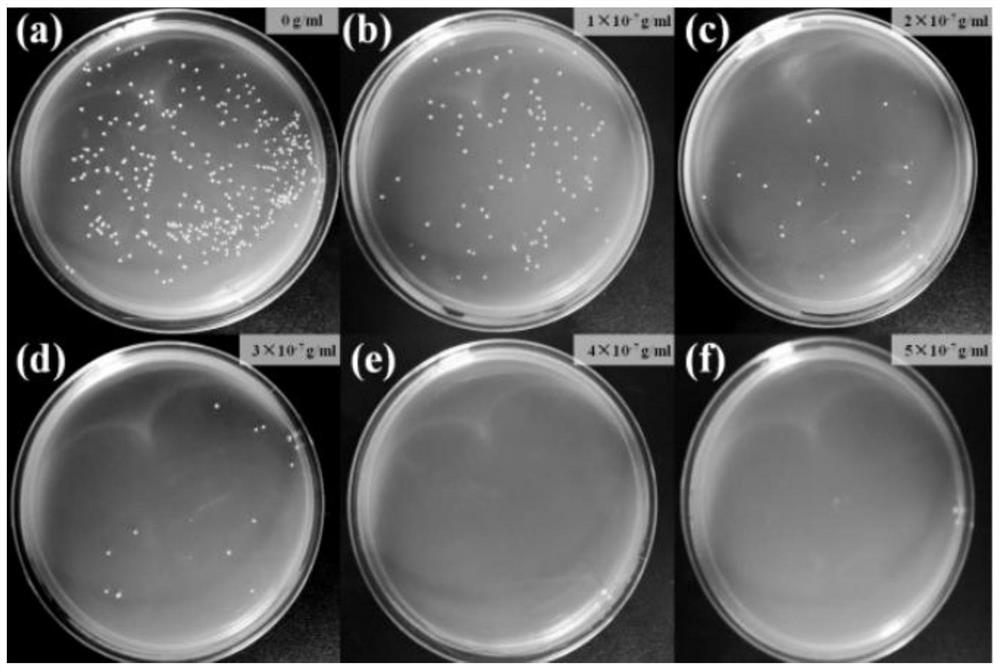

[0019] The antibacterial agent prepared in this embodiment has different antibacterial rates in different concentrations. Such as figure 1 shown, for a nanometer copper concentration of 1×10 -7 g / ml, 2×10 -7 g / ml, 3×10 -7 g / ml, 4×10 -7 For the antibacterial agent of g / ml, the anti...

Embodiment 2

[0021] An ultra-high-efficiency copper nanoparticle antibacterial textile. The antibacterial textile is composed of core-shell copper nanoparticle as the main antibacterial material, which is attached to the surface and interior of textile fibers through ultrasonic technology. The process is simple and environmentally friendly. The concentration of nano-copper in the high-efficiency copper nanoparticle antibacterial textiles was 8×10 -7 g / ml, 1×10 -6 g / ml, 2×10 -6 g / ml. During preparation, according to the method in Example 1, the concentration of 8 × 10 -7 g / ml, 1×10 -6 g / ml, 2×10 -6 Each 100ml of nano-copper dispersion liquid of g / ml was ultrasonically treated for 10min to make it evenly dispersed, and then 1g of each textile that had been boiled and cleaned was put into it respectively, and ultrasonically treated for 20min. Finally, rinse with distilled water and dry to obtain ultra-high-efficiency nano-copper antibacterial textiles.

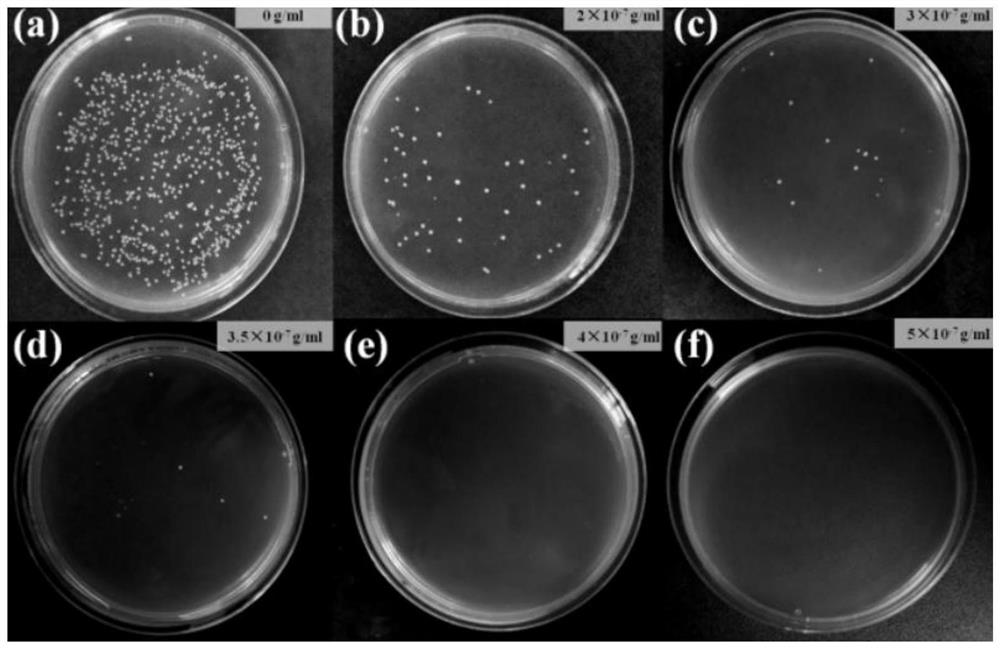

[0022] The prepared antibacteria...

Embodiment 3

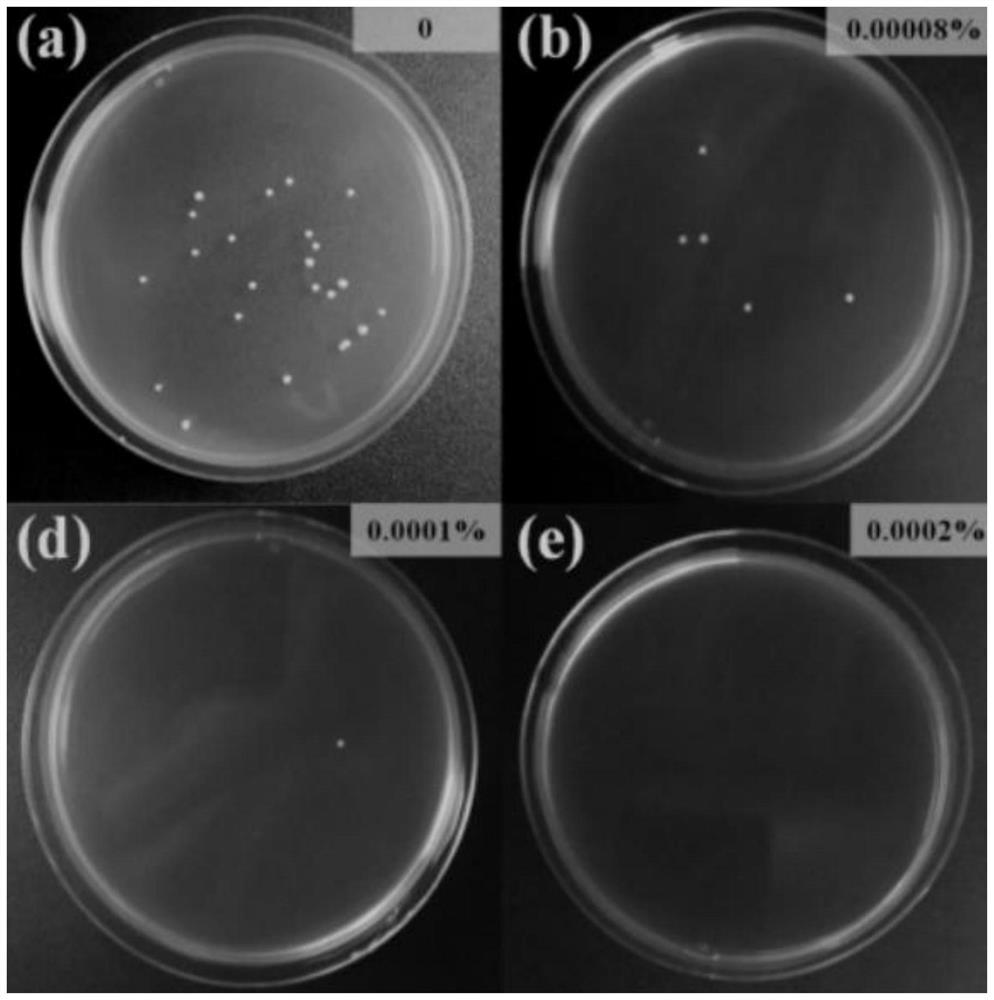

[0024] A highly washable copper nanoparticle antibacterial textile. The antibacterial textile described in this embodiment has high washability on the basis of high-efficiency antibacterial. In view of the 50 times of washing resistance currently promoted in the market, the antibacterial textile has reached 100 times of washing without failure. According to the raw material characteristics and processing methods of this embodiment, it can be washed 200 times, 500 times, or even 1000 times without failure, and can widely meet the different needs of the civilian market and the military field. Considering the loss of antibacterial materials before and after washing, on the basis of keeping the characteristics of textiles unchanged, a copper treatment concentration of 5×10 was developed. -6 g / ml, 1×10 -5 g / ml, 2×10 -5 g / ml of high washable antibacterial textiles. The preparation method is the same as in Example 2. Since the amount of copper added is on the order of 1 / 100,000, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com