A kind of rubber band glue for machine and preparation method thereof

A rubber band and machine technology, used in adhesives, non-polymer organic compound adhesives, adhesive additives, etc., can solve the problems of high brittleness, inability to withstand impact and extension, and whitening of the adhesive layer, and achieve compatibility. Good, no whitening at the bonding area, not easy to whiten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

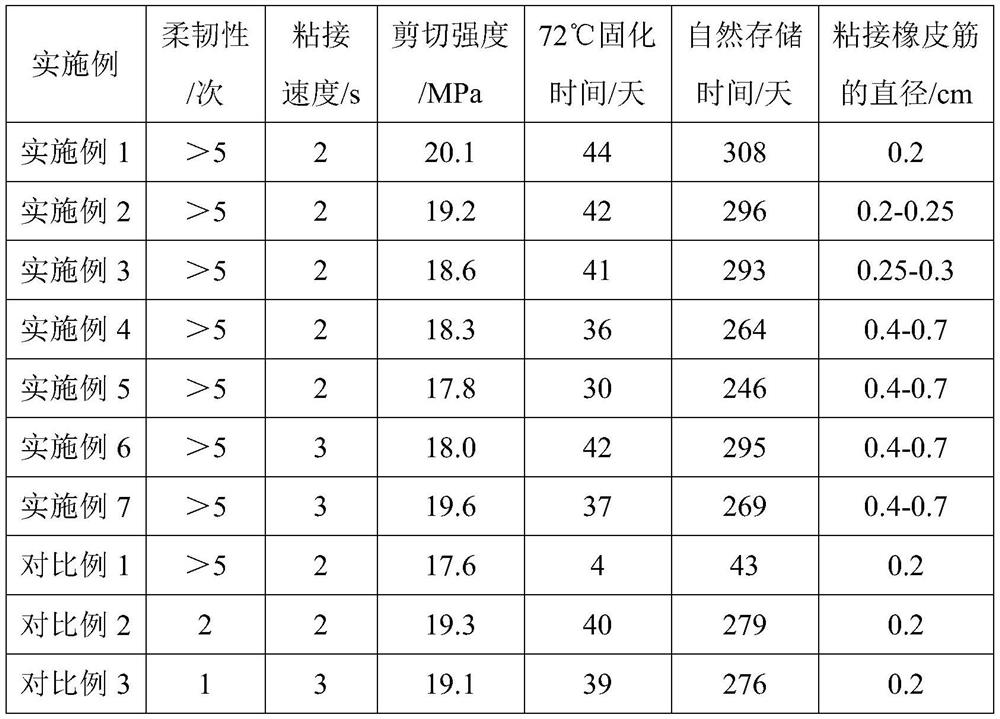

Embodiment 1

[0031] A rubber band glue for machines, comprising the following raw materials in mass percentage: 92.5% of ethyl α-cyanoacrylate, 7% of terpolymer of vinyl acetate resin, and 0.5% of polyether polyol.

[0032] The preparation method of rubber band glue for above-mentioned machine comprises steps as follows:

[0033] Add α-ethyl cyanoacrylate into a three-necked flask, add polyether polyol, and stir evenly at room temperature; then add vinyl acetate resin terpolymer, stir at room temperature to dissolve, and then stir for 0.5h to obtain the product.

Embodiment 2

[0035] A rubber band glue for machines, comprising the following raw materials in mass percentage: 91.5% of ethyl α-cyanoacrylate, 8% of terpolymer of vinyl acetate resin, and 0.5% of polyether polyol.

[0036] The preparation method of rubber band glue for above-mentioned machine comprises steps as follows:

[0037] Add α-ethyl cyanoacrylate into a three-necked flask, add polyether polyol, and stir evenly at room temperature; then add vinyl acetate resin terpolymer, stir at room temperature to dissolve, and then stir for 0.5h to obtain the product.

Embodiment 3

[0039] A rubber band glue for machines, comprising the following raw materials in mass percentage: 89.5% of ethyl α-cyanoacrylate, 10% of terpolymer of vinyl acetate resin, and 0.5% of polyether polyol.

[0040] The preparation method of rubber band glue for above-mentioned machine comprises steps as follows:

[0041] Add α-ethyl cyanoacrylate into a three-necked flask, add polyether polyol, and stir evenly at room temperature; then add vinyl acetate resin terpolymer, stir at room temperature to dissolve, and then stir for 0.5h to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com