Float glass batching device and batching method thereof

A float glass and silo technology, which is applied in the field of float glass batching devices, can solve the problems affecting the viscosity of the kiln glass liquid, the temperature of the bottom of the thermal permeability pool, the color property of the hardening speed glass, the reduction of iron impurity adsorption, and the efficiency of iron removal Reduce and other problems, achieve the effect of saving cleaning, stabilizing iron content and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

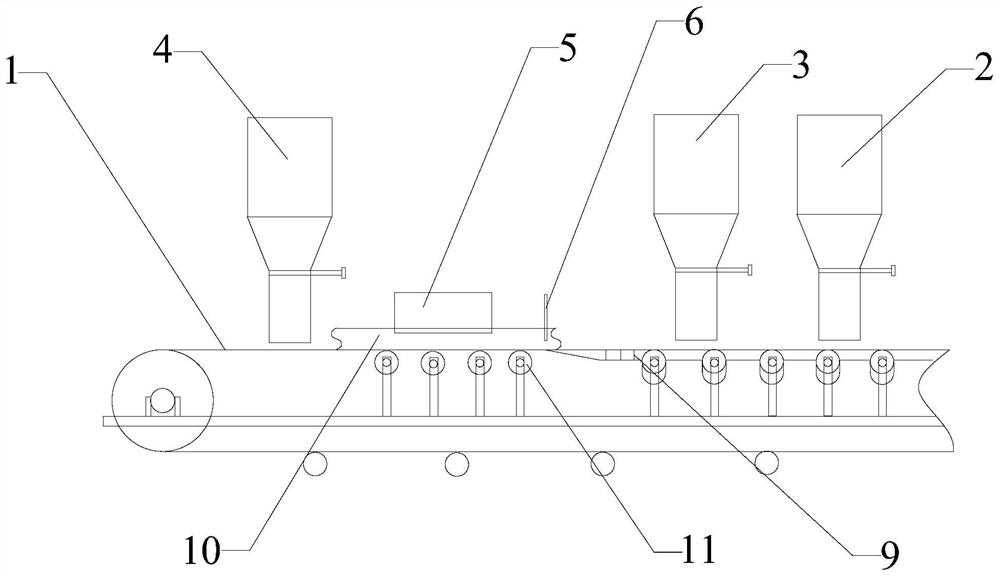

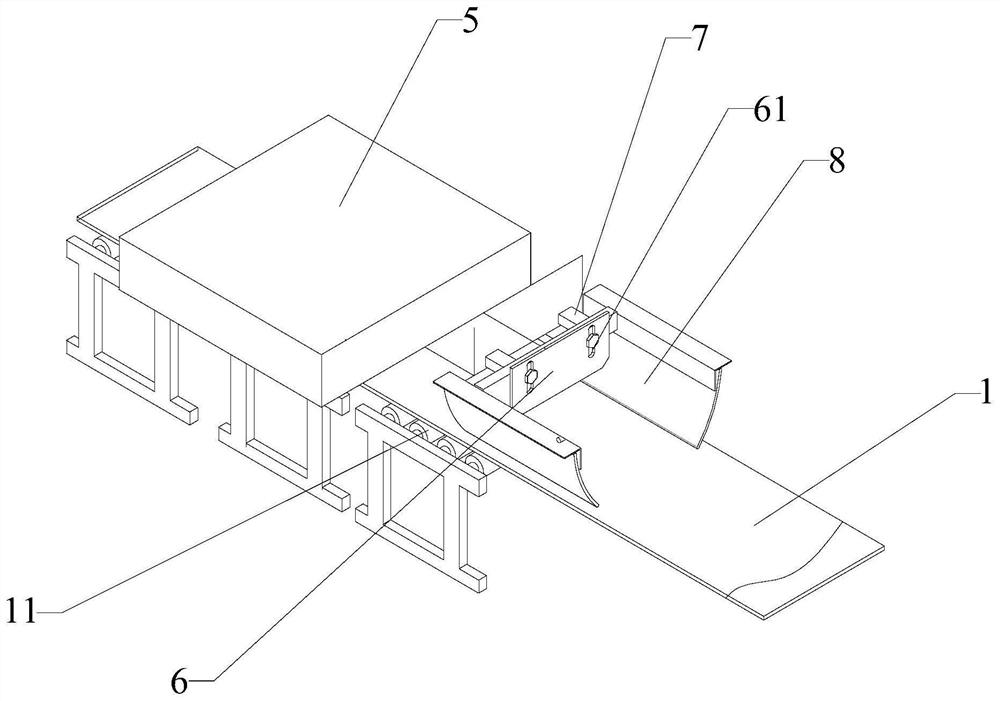

[0050] A float glass batching device, comprising a collection belt 1, a silica sand silo, a dolomite silo, a soda ash silo, a limestone silo, a feldspar silo 2, a Glauber's salt silo 3, an iron powder silo 4 and an iron remover 5; The collecting belt 1 is a straight plate type collecting belt 1 whose upper surface is parallel to the horizontal plane; the silica sand silo, dolomite silo, soda ash silo, limestone silo, feldspar silo 2, Glauber's salt silo 3, iron remover 5 and iron powder silo 4 are sequentially arranged above the collection belt 1 along the conveying direction of the collection belt 1; the part of the collection belt 1 below the iron remover 5 is higher than other parts of the collection belt 1. The feeding end of the iron remover 5 is provided with a scraper baffle 6 . Above the feed end of the iron remover 5 is provided with a fixed frame 7, and the scraper baffle 6 is provided with more than two vertical strip holes 61, and the scraper baffle 6 passes throug...

Embodiment 2

[0052] A method for batching float glass, comprising the steps of:

[0053] Step 1: The collection belt passes through the bottom of multiple silos in turn, so that the other float glass ingredients except iron powder fall on the collection belt in turn;

[0054] Step 2: The float glass ingredients on the collecting belt pass under the iron remover to remove iron-containing impurities in the material;

[0055] Step 3: The collection belt passes under the iron powder silo, so that the iron powder is added to the float glass batch after the iron remover removes the iron-containing impurities in the material.

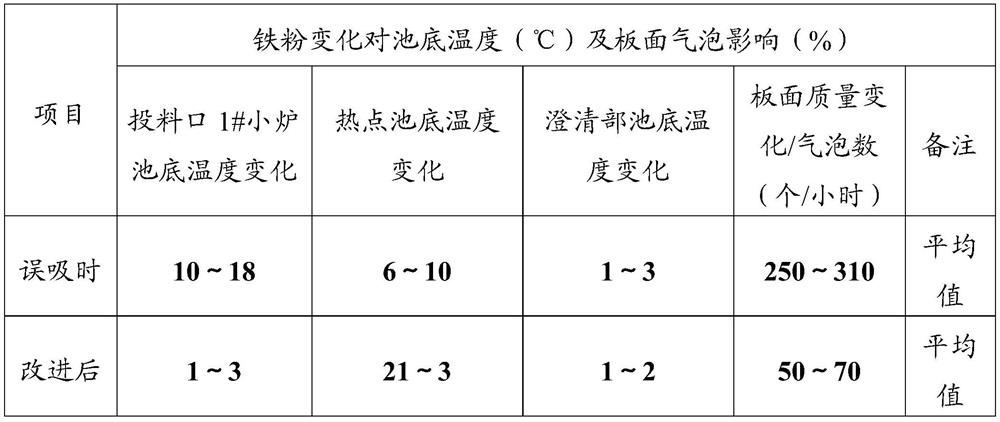

[0056] The changes of the pool bottom temperature and glass surface bubbles before and after the improvement of the float glass batching device are shown in Table 1 below:

[0057] Table 1. Summary and statistical analysis of iron powder changes on pool bottom temperature and board surface air bubbles

[0058]

[0059] To sum up, in the float glass batching device pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com