Cooking utensil with liner suction prevention function

A technology of cooking utensils and functions, applied in pressure cookers and other directions, can solve the problems of reducing gas flow speed, slow air intake in exhaust channels, and reducing user experience, so as to reduce energy loss, clear the direction of air conduction, and improve user experience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

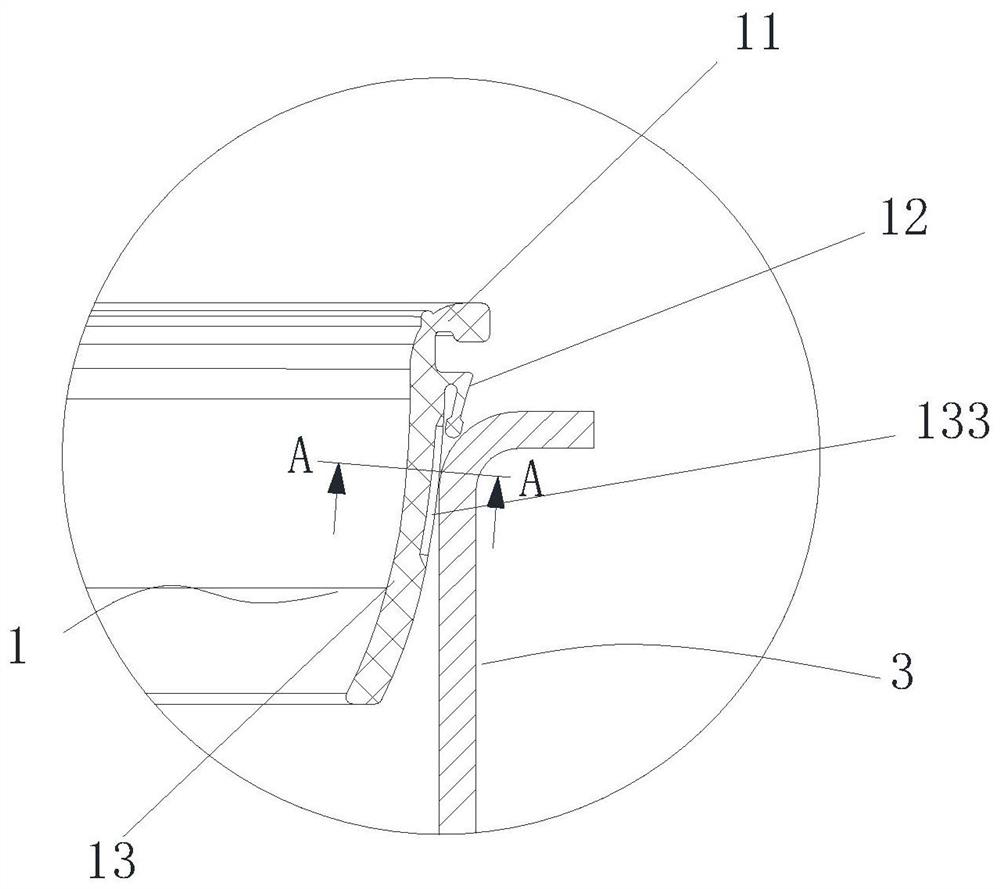

[0062] Embodiment 1, in the first position, the skirt portion 122 abuts against the inner liner 31 of the inner liner 3 , compared with the prior art when the inner liner is closed by the pot lid, the upper lip " As far as the technical solution of sealing is realized by increasing the contact area on the edge of the inner container, the end of the skirt portion 122 in this application abuts against the edge 31 of the inner container for sealing, which can be Sealing is achieved when pressing up, and when the pressure is released, due to the small contact area, the adsorption force between it and the liner edge 31 is reduced, which facilitates the introduction of external air, so as to quickly form a seal between the skirt portion 122 and the liner edge 31 The air intake gap 5.

Embodiment approach 2

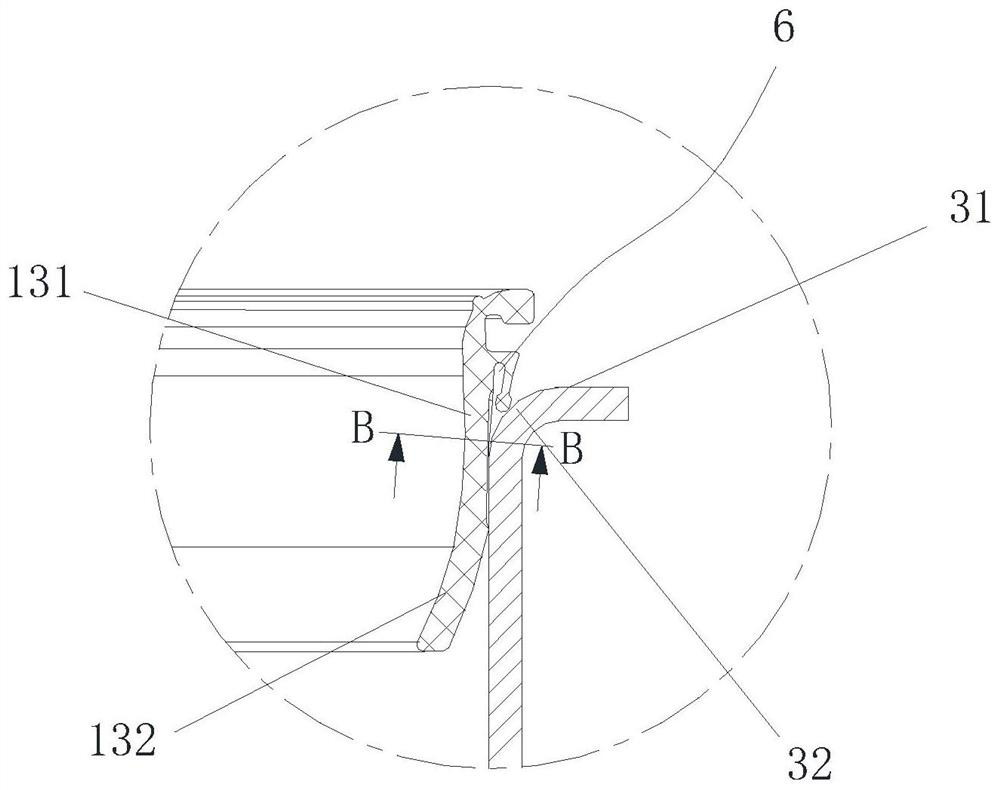

[0063] Embodiment 2, such as image 3 As shown, in the first position, the skirt portion 122 abuts against the chamfered portion 32 , and preferably, the cross section of the chamfered portion 32 is arc-shaped. In this embodiment, at the first position, one end of the skirt portion 122 abuts against the chamfered portion 32 , and the arc-shaped chamfered portion 32 can form a stop for the skirt portion 122 , which helps the abutting seal between the free end and the inner wall of the liner 3. Compared with the implementation of abutting against the inner wall of the liner 31, in this embodiment, after the pressure is released, as Figure 6 As shown, under the action of external air, the skirt portion 122 can break away from the contact with the inner container 3 more quickly, and form the air intake gap 5 to facilitate the rapid influx of external air.

[0064] If the sealing ring 1 is applied to a pressure cooker, then as Figure 7 As shown, when the pot cover 2 is fastened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com