Multi-angle stirring, standing and separating equipment for cake stock solution

A static separation, multi-angle technology, applied in the XX field, can solve the problems of the influence of the reputation of the cream, the effect of the whipping is not ideal, and the taste of the cream is affected, and achieves the effect of simple operation and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

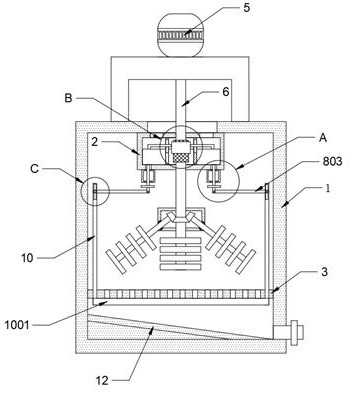

[0028] Embodiment 1: The multi-angle stirring mechanism includes a first bevel gear 901 set on the rotating rod 6 in the multi-angle stirring box 9, and the left and right side walls of the multi-angle stirring box 9 are connected to the stirring rod 903 through bearing rotation, The upper end of the stirring rod 903 is fixedly connected with the second bevel gear 902, the first bevel gear 901 meshes with the second bevel gear 902, the lower ends of the rotating rod 6 and the two stirring rods 903 are fixedly connected with the auxiliary stirring rod 904, the motor 5 The output end drives the rotating rod 6 to rotate. Through the multi-angle stirring mechanism, the rotating rod 6 drives the first bevel gear 901 to rotate, and the first bevel gear 901 meshes with the second bevel gear 902 to drive the stirring rod 903 to rotate, thereby driving multiple The angled auxiliary stirring rod 4 stirs the cake liquid, and the stirring effect is very good. During the stirring process, t...

Embodiment 2

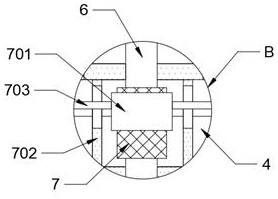

[0029] Embodiment 2: The automatic unloading mechanism of the cake raw liquid includes a reciprocating threaded rod 7, which is a hollow structure, and the reciprocating threaded rod 7 is set on the rotating rod 6, and the reciprocating threaded rod 7 is threadedly connected with a threaded sleeve 701, and a threaded sleeve 701 The left and right ends of the left and right ends are all fixedly connected with the connecting rod 704, and the top and bottom inner walls of the cake raw liquid feeding box 2 located on both sides of the rotating rod 6 are fixedly connected with the limiting plate 702, and the cake raw liquid feeding box 2 is fixedly installed with a Cake raw liquid storage box 4, the limiting plate 702 is provided with a limiting through hole, the fixed rod 703 slides through the limiting through hole and the top wall of the cake raw liquid storage box 4 and is fixedly connected with the first lower liquid plate 705, and the cake raw liquid is unloaded The two ends o...

Embodiment 3

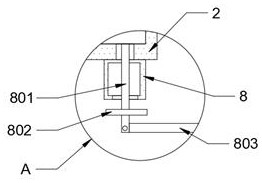

[0030]Embodiment 3: The auxiliary separation mechanism includes a driving rod 801 fixedly connected to the bottom surface of the first lower liquid plate 705, the driving rod 801 slides through the lower liquid pipe and the auxiliary lower material box 8 and is hinged with a hinged rod 803, which is located in the auxiliary lower material box 8 The driving rod 801 below is covered with a second lower liquid plate 802, the other end of the hinged rod 803 is fixedly connected to the limit block 804, and the separation rod 10 is installed sliding through the static partition plate 3, and the lower ends of the two separation rods 10 The same separation plate 1001 is fixedly connected, and the upper end of the separation rod 10 is provided with a limit groove 1002, and the limit block 804 is slidably installed in the limit groove 1002; the limit block 804 slides in the limit groove 1002, driving the separation rod 10 to move down , to drive the separation plate 1001 to move down, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com