High-temperature gas cooled reactor steam generator small-flow cooling system and control method

A technology for steam generators and high-temperature gas-cooled reactors, which is applied to the primary side of steam generators, cooling devices, and greenhouse gas reduction. It can solve the problems of cold shock and long time of steam generators, and achieve both efficiency and economical efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

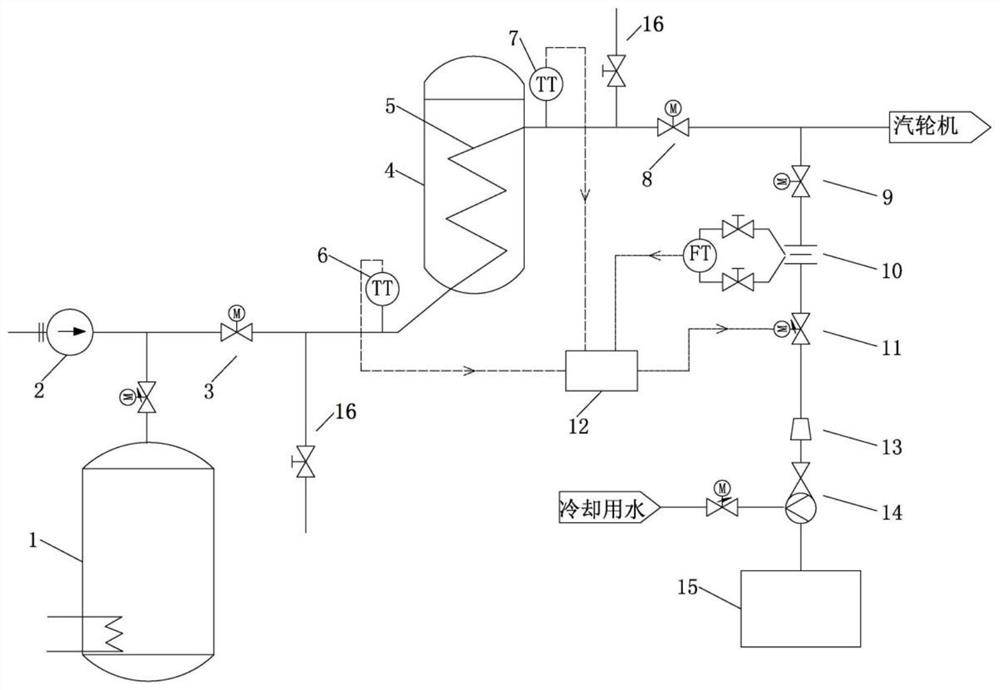

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

[0032] The present invention mainly lies in that an auxiliary boiler room is set to generate auxiliary steam, the heat exchange tube of the steam generator is cooled through the main water supply pipe, and a small bypass pipe is arranged on the main steam pipe, which is discharged into a pool after being enlarged and reduced in temperature; Temperature measuring points are set at the inlet and outlet of the heat exchange tube, and high-precision regulating valves and flowmeters are set on the bypass small tubes, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com