Construction method for reducing safety risk of ribbed anchor rod retaining wall reverse construction method

A safety risk and construction method technology, applied in the direction of excavation, artificial island, sheet pile wall, etc., can solve the problems of shortened construction safety and high safety risk, and achieve the effect of improving work efficiency, increasing contact area and reducing safety risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

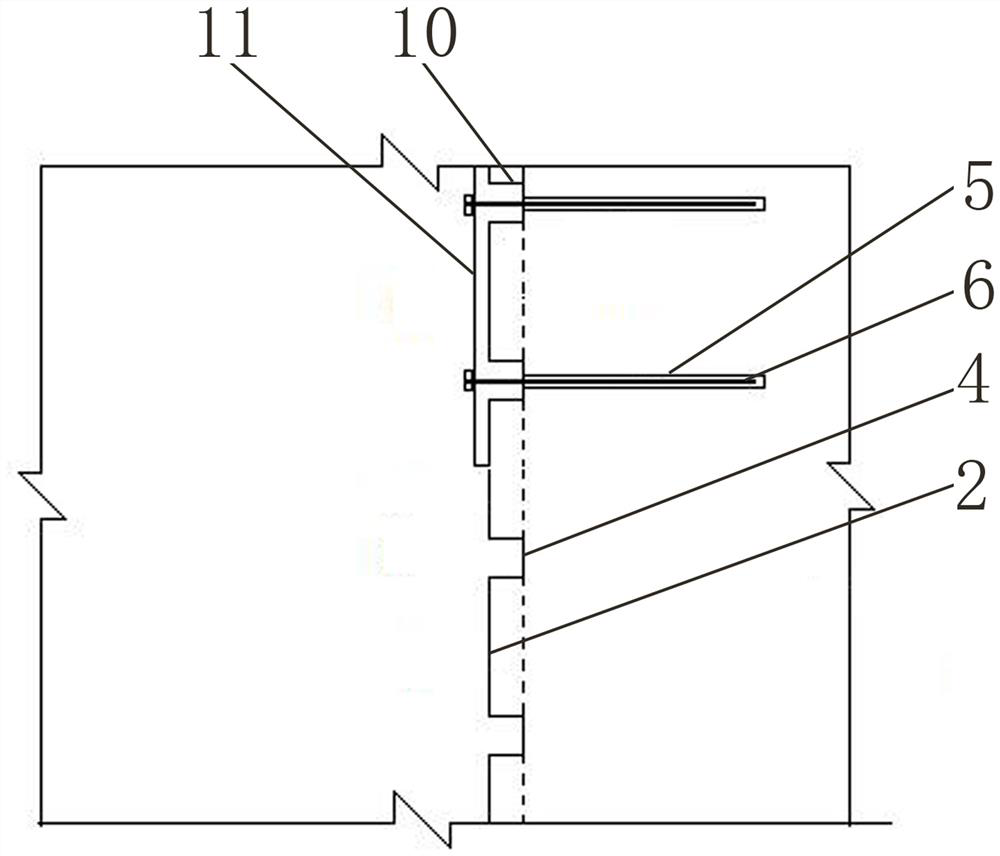

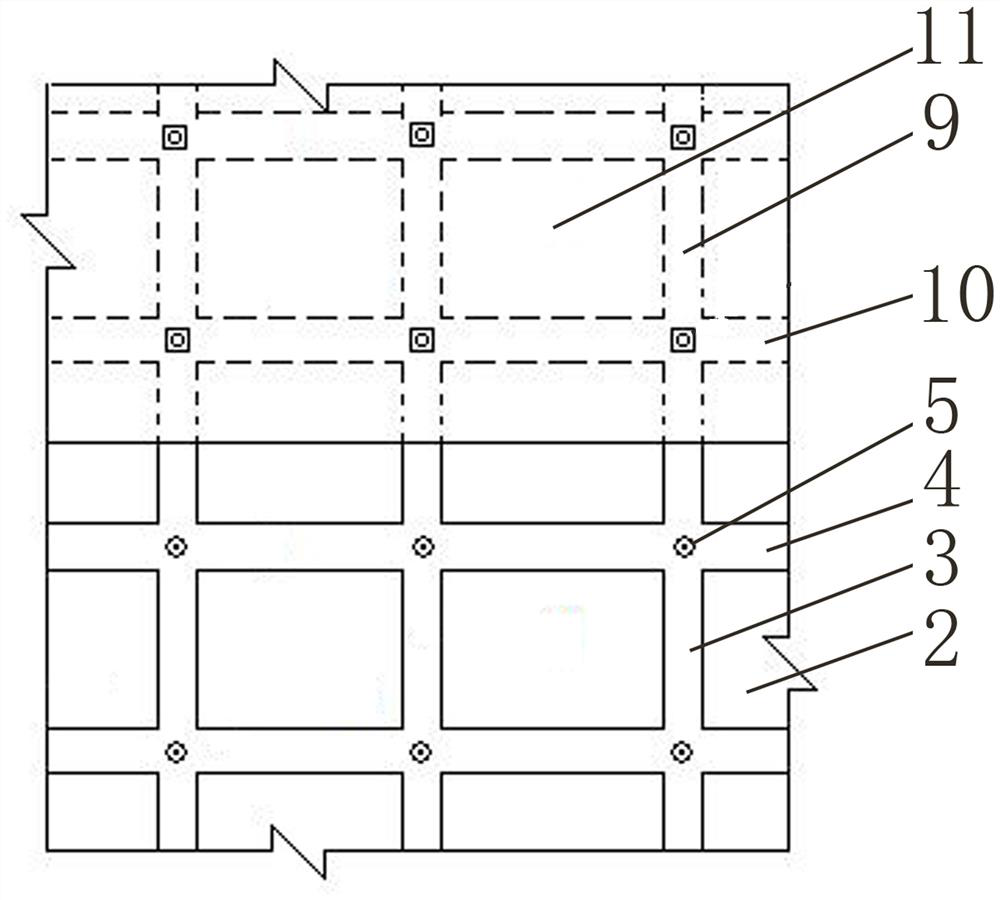

[0047] A construction method for reducing the safety risk of the reverse construction method of a ribbed anchor retaining wall, said method comprising the following steps:

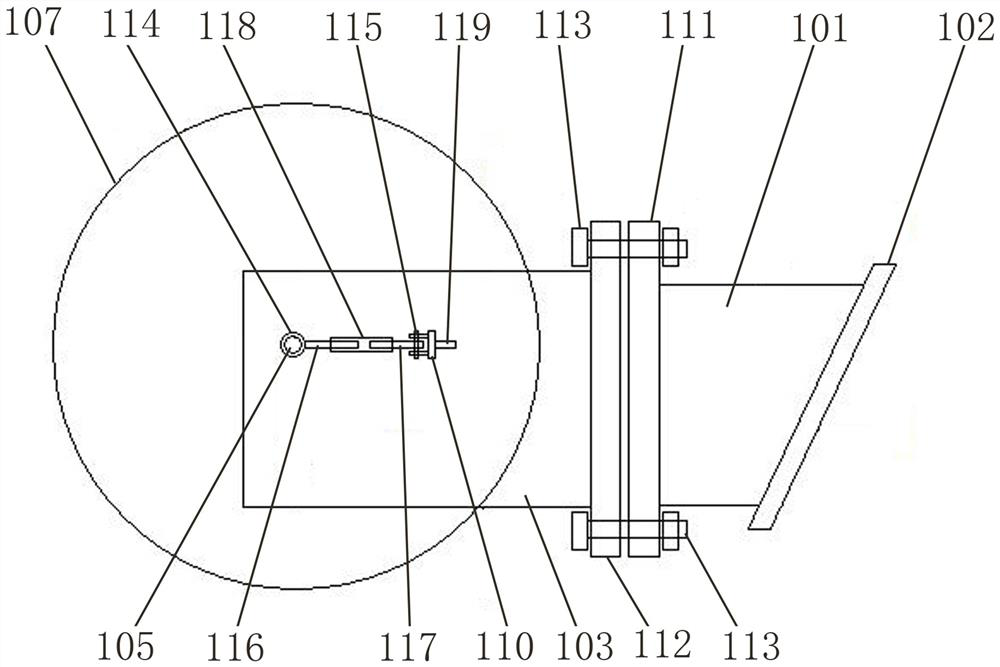

[0048] S1: Preparation of the double-knife surrounding rock cutting tool: the double-knife surrounding rock cutting tool includes a connecting frame 101, the right end surface of the connecting frame 101 is fixed with a first coupling seat 102, and the left end surface is provided with a detachably fixed Knife rest 103; the left end of knife rest 103 rotates and is provided with longitudinally placed driving shaft 104, and the front side and the rear side of driving shaft 104 are all provided with longitudinally placed driven shaft 105, and driven shaft 105 passes universal joint The shaft device 106 is connected with the driving shaft 104 in transmission; the outer ends of the two driven shafts 105 are provided with horizontally upright saw blades 107, and the front surface and the rear surface of the saw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com