A kind of antistatic fabric and its production process

A technology of anti-static fabrics and anti-static coatings, applied in the field of fabrics, can solve the problems of reduced anti-static properties of fabrics, damage to conductive fibers, and breakage of conductive fibers, and achieve the effects of increasing moisture permeability, reducing static electricity, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

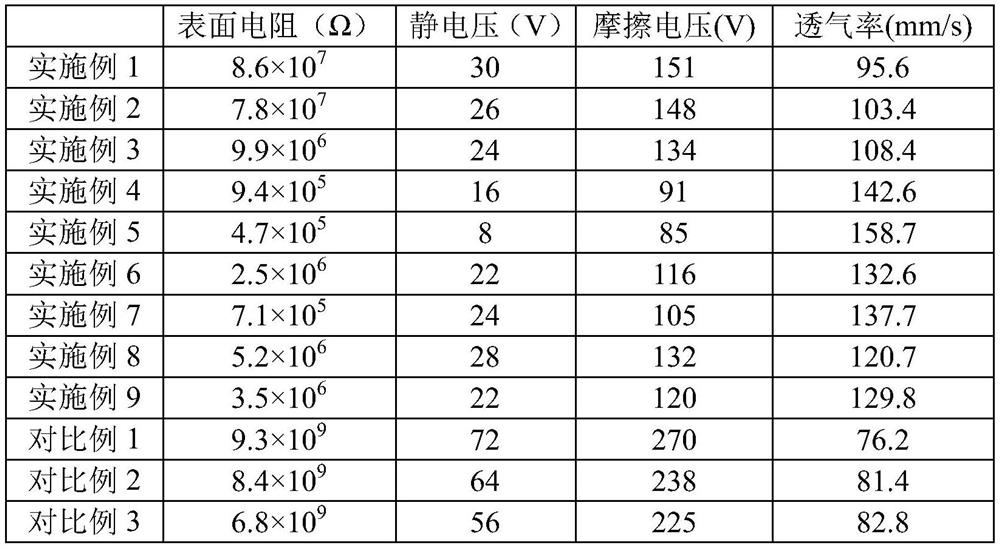

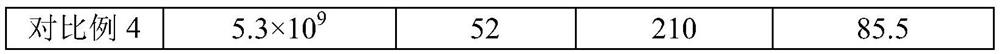

Examples

Embodiment 1

[0041]An anti-static fabric, comprising a base layer, an anti-static layer and a surface layer arranged in sequence, the base layer is woven from cotton fibers, the anti-static layer is formed by coating the base layer with anti-static paint, and the surface layer is made of polyester and polyamide fibers Blended, of which polyester accounts for 70% and polyamide fiber accounts for 30%;

[0042] Antistatic coating, including by weight 20kg of polypropylene glycol, 30kg of polyester polyol, 10kg of polyetheramine, 5kg of graphene, 4kg of nano-tin dioxide, 10kg of absolute ethanol, 0.5kg of polyethylene glycol, 1 kg of CTAB and hypophosphorous acid Sodium 1kg, polyester polyol is obtained by polycondensation reaction of adipic acid and ethylene glycol;

[0043] The preparation of antistatic coating includes the following steps: 1) adding polypropylene glycol, polyester polyol and polyetheramine into the reaction kettle, and stirring at 130° C. for 2 hours; 2) adding sodium hypop...

Embodiment 2

[0048] An anti-static fabric, comprising a base layer, an anti-static layer and a surface layer arranged in sequence, the base layer is woven from cotton fibers, the anti-static layer is formed by coating the base layer with anti-static paint, and the surface layer is made of polyester and polyamide fibers Blended, of which polyester accounts for 70% and polyamide fiber accounts for 30%;

[0049] Antistatic coating, including by weight 30kg of polypropylene glycol, 20kg of polyester polyol, 12kg of polyetheramine, 10kg of graphene, 5kg of nano-tin dioxide, 12kg of absolute ethanol, 1kg of polyethylene glycol, 2 kg of CTAB and sodium hypophosphite 2kg, polyester polyol is obtained by polycondensation reaction of adipic acid and diethylene glycol;

[0050] The preparation of antistatic coating includes the following steps: 1) adding polypropylene glycol, polyester polyol and polyetheramine into the reaction kettle, and stirring at 150 ° C for 1 hour; 2) adding sodium hypophosphi...

Embodiment 3

[0055] An anti-static fabric, comprising a base layer, an anti-static layer and a surface layer arranged in sequence, the base layer is woven from cotton fibers, the anti-static layer is formed by coating the base layer with anti-static paint, and the surface layer is made of polyester and polyamide fibers Blended, of which polyester accounts for 70% and polyamide fiber accounts for 30%;

[0056] Antistatic coating, including by weight 25kg of polypropylene glycol, 20kg of polyester polyol, 15kg of polyetheramine, 8kg of graphene, 6kg of nano-tin dioxide, 15kg of absolute ethanol, 0.7kg of polyethylene glycol, 3 kg of CTAB and hypophosphorous acid Sodium 2kg, polyester polyol is obtained by polycondensation reaction of adipic acid and ethylene glycol;

[0057] The preparation of antistatic coating includes the following steps: 1) adding polypropylene glycol, polyester polyol and polyetheramine into the reaction kettle, and stirring at 140° C. for 2 hours; 2) adding sodium hypo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com