Quaternary phosphonium salt type organic silicon latex and preparation method thereof

A technology of silicone emulsion and quaternary phosphonium salt, applied in the field of latex, can solve the problems of mold growth, easy yellowing of latex sponge, etc., and achieve the effect of increasing solvent resistance, improving product quality, and not polluting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

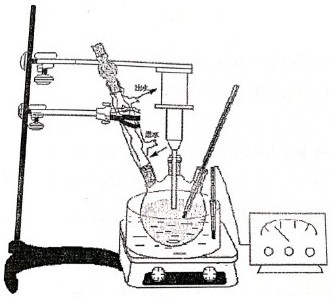

Image

Examples

Embodiment Construction

[0022] A quaternary phosphonium salt-type silicone latex, consisting of the following raw materials in parts by mass: 15 parts of quaternary phosphonium salt-type silicone emulsion, 70 parts of latex, 5 parts of coupling agent, 3 parts of stabilizer, 2 parts of initiator, solidification 3 parts of agent, 2 parts of foaming agent. Described latex is natural latex, and coupling agent is vinyltrimethylsilane, and described stabilizing agent is sodium bisulfite, and described initiator is ammonium persulfate, and described coagulating agent is slow coagulating agent sodium silicofluoride, The foaming agent is sodium myristate, and the specific preparation method of the quaternary phosphonium salt type silicone latex is as follows:

[0023] (1) Step 1: Take triphenylphosphine, 1,3-dibromopropane and reaction solvent in a molar ratio of 1:1, add them to a three-necked flask reactor, and stir and heat under reflux at 130°C under nitrogen protection conditions Cool for 12 h, filter, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com