Concrete base material applied to extremely cold environment

An extremely cold environment, concrete technology, applied in the field of construction concrete, can solve the problems of unusable concrete, concrete base materials cannot be mixed normally, and reduce the hardness of concrete, so as to speed up the mixing rate, improve the mixing effect, and improve the hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

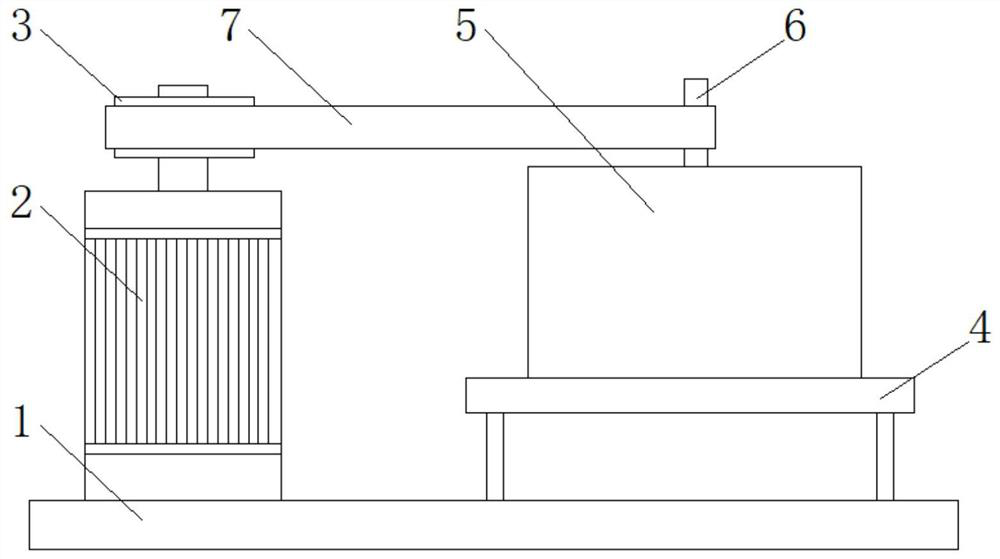

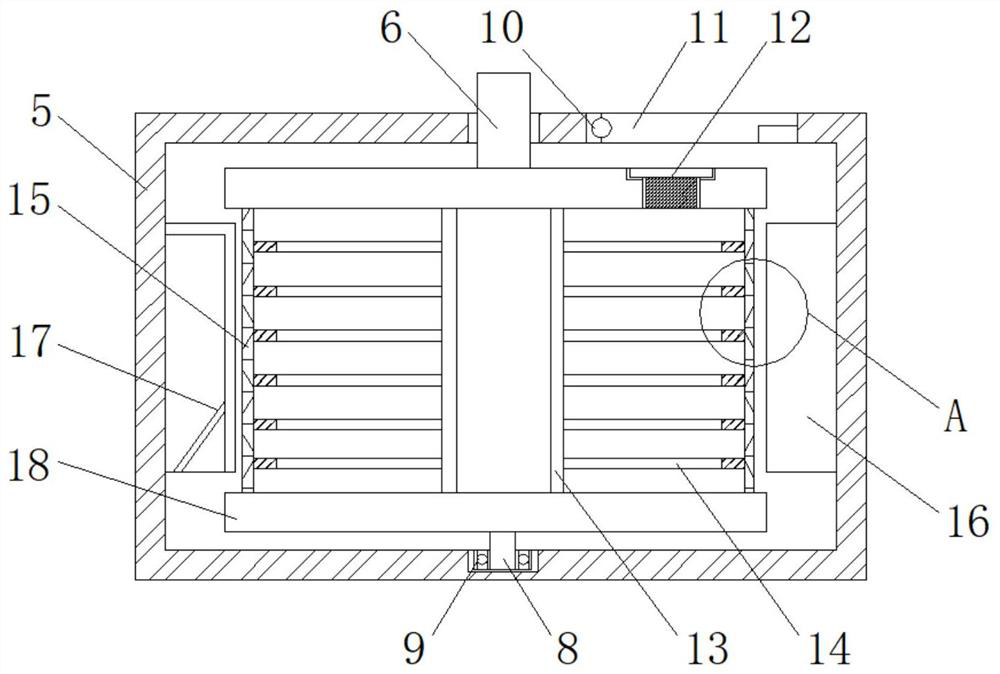

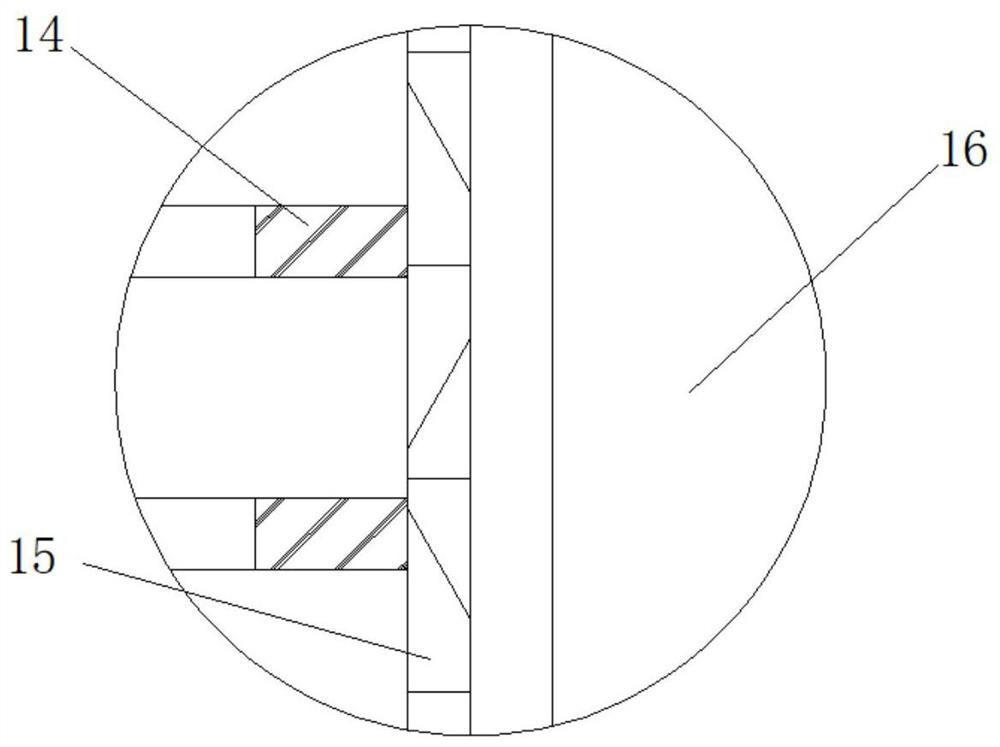

[0038] see Figure 1-3 , a concrete base material used in extremely cold environments, its composition includes: cement, machine-made sand, gravel, high-efficiency water reducer, mortar, hydrogel, ordinary sand and admixture, and its composition is based on the amount of a single Calculated, the dosage of each component of the concrete is as follows: 510 to 550 kilograms per cubic meter of cement, 820 to 860 kilograms per cubic meter of machine-made sand, and 950 kilograms per cubic meter of crushed stone to 1,100 kilograms, 7 to 11 kilograms per cubic meter of superplasticizer, 115 to 125 kilograms per cubic meter of mortar, and 120 kilograms to 1 One hundred and sixty kilograms, 30 to 70 kilograms per cubic meter of admixture, can realize the adjustment of the concrete base material composition, through the self-heating component added by itself, in the process of mixing cement and other concrete base materials, exothermic expansion, Make the internal heat storage of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com