Method and mold structure for conical rubber spring vulcanization mold full-automatic mold opening

A technology of vulcanization molds and rubber springs, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of repeated adjustment of the installation and positioning of the vulcanization molds, easy wear and vulcanization quality of the vulcanization molds, and difficult vulcanization operations, so as to improve the use of the molds. The effect of working conditions and vulcanized product ejection conditions, reducing operating labor intensity and safety risks, and reducing costs and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

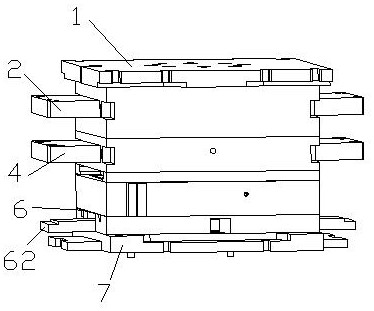

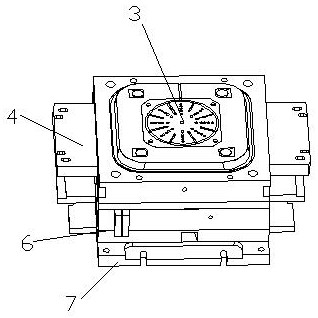

[0038] A kind of automatic mold opening mold structure of conical rubber spring vulcanization mold, such as figure 1 with figure 2 As shown, the mold structure of the entire vulcanization mold includes an upper mold 1, an injection cylinder 2, an injection insert 3, a middle mold 4, a flap mold 5, a lower mold 6, and a bottom mold 7 from top to bottom. The lower plate 8 and the upper mold 1 fixed to the vulcanization equipment are fixed to the upper plate 82 of the vulcanization equipment to fix the entire mold to the vulcanization equipment. When vulcanizing and closing the mold, the upper mold 1 injects the rubber in the injection cylinder 2 through the injection insert. 3. The flow channel is injected into the product cavity surrounded by the middle mold 4, the valve mold 5 and the lower mold 6 to form a vulcanized product of conical rubber spring; the valve mold 5 is divided into two symmetrical pieces, and the mold is opened after vulcanization. The flap mold 5 can be s...

Embodiment 2

[0043] This embodiment is basically the same as the above-mentioned embodiment, the difference is: in this embodiment: as Figure 15 As shown, two bead 64 is provided with U-shaped groove 65 on the side close to valve mold 5, and at this moment, the flange 52 of valve mold 5 is convex at the side wall place of valve mold 5, no longer the same as in embodiment one. Likewise, the bottom of the flange 52 is flush with the bottom of the valve mold 5 .

Embodiment 3

[0045] This embodiment is basically the same as the above embodiment, except that in this embodiment, the slot 71 on the bottom mold 7 can also be arranged on the bottom surface, but this structure is not as convenient as the first embodiment for alignment and positioning.

[0046] It can be seen from the above-mentioned embodiments that the present invention also relates to a fully automatic mold opening method for a conical rubber spring vulcanization mold, in which the glue injection insert 3 of the vulcanization mold is fixed on the middle mold 4 of the mold and moves up and down together with the middle mold 4 In this way, the automatic separation between the mold injection insert 3, the injection cylinder 2 and the vulcanized product is completed, and the automatic operation of the injection insert 3 is realized; the middle mold 4, the flap mold 5 and the lower mold 6 of the vulcanization mold are used. The way of setting the guide mechanism between them makes the valve m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com