Automatic pallet feeding device and method thereof

A pallet and automatic technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of potential safety hazards, time-consuming and labor-intensive problems, and achieve the effect of reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

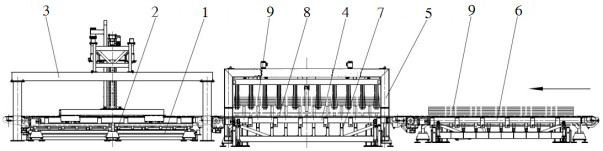

[0034] refer to figure 1 and figure 2 , the embodiment of the present invention proposes an automatic pallet loading device, including: pallet conveying roller 1, pallet conveying chain 2, plate stack clamping position conveying chain 4, entrance conveying chain 6 and control system; one end of pallet conveying chain 2 Opposite to one side of the pallet conveying roller table 1, a pallet lifting mechanism 3 is arranged between the pallet conveying roller table 1 and the pallet conveying chain 2; one end of the pallet conveying chain 4 is opposite to one end of the pallet conveying chain 2 , the upper part of the conveying chain 4 at the plate stack clamping position is provided with a plate stack clamping mechanism 5; the inlet conveyor chain 6 is docked at the other end of the conveying chain 4 at the plate stack clamping position; the signal output end of the control system is respectively connected with the pallet conveying chain 2 , The pallet lifting mechanism 3, the bo...

Embodiment 2

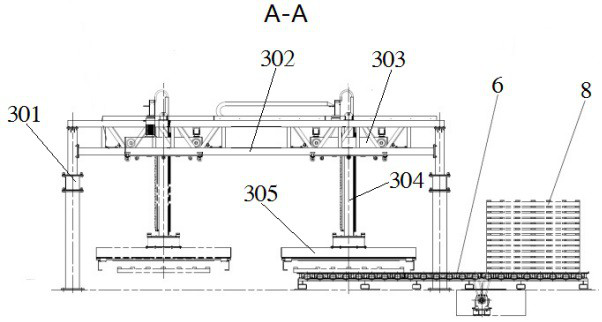

[0040] refer to image 3 and Figure 4 On the basis of Embodiment 1, the pallet lifting mechanism 3 includes: a pair of bridge frames 301, a pair of rail beams 302, and a traverse trolley 303; The two ends of the two track beams 302 are fixedly connected to the two bridge frames 301 respectively; the two sides of the traverse trolley 303 are rolled and assembled on the two track beams 302 respectively, and the traverse trolley 303 is provided with a lifting mechanism 304 and Grab mechanism 305 .

[0041] The traverse trolley 303 is driven by a motor, and the traverse trolley 303 is provided with a working position proximity switch and a lifting position proximity switch. The lifting upper limit switch, the lower lifting limit switch and the wire encoder on the pallet lifting mechanism 3 are all set in the lifting mechanism. 304 on.

Embodiment 3

[0043] refer to image 3 and Figure 4 On the basis of Embodiment 3, the lifting mechanism 304 includes a vertical column 306 and a lifting motor 307, the vertical column 306 is vertically slidably assembled on the traverse trolley 303, and one side of the vertical column 306 is provided with a rack 311, A gear is connected to the main shaft of the lift motor 307 , and the gear is matched with the rack 311 .

[0044] When the lift motor 307 drives the gear to rotate, the gear can crawl up and down along the rack 311 relatively, and drive the vertical column 306 to rise or fall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com