Spinning roller and process thereof

A roller and textile technology, applied in the field of textile accessories processing, can solve problems such as affecting yarn drafting and affecting straightness, and achieve the effects of improving deformation resistance, good strength and avoiding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

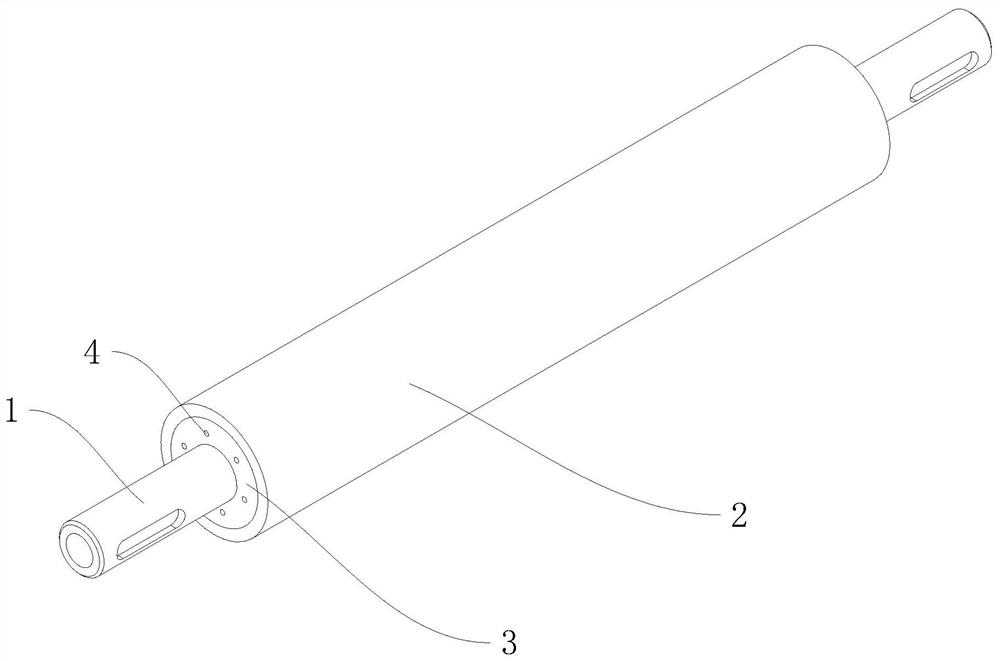

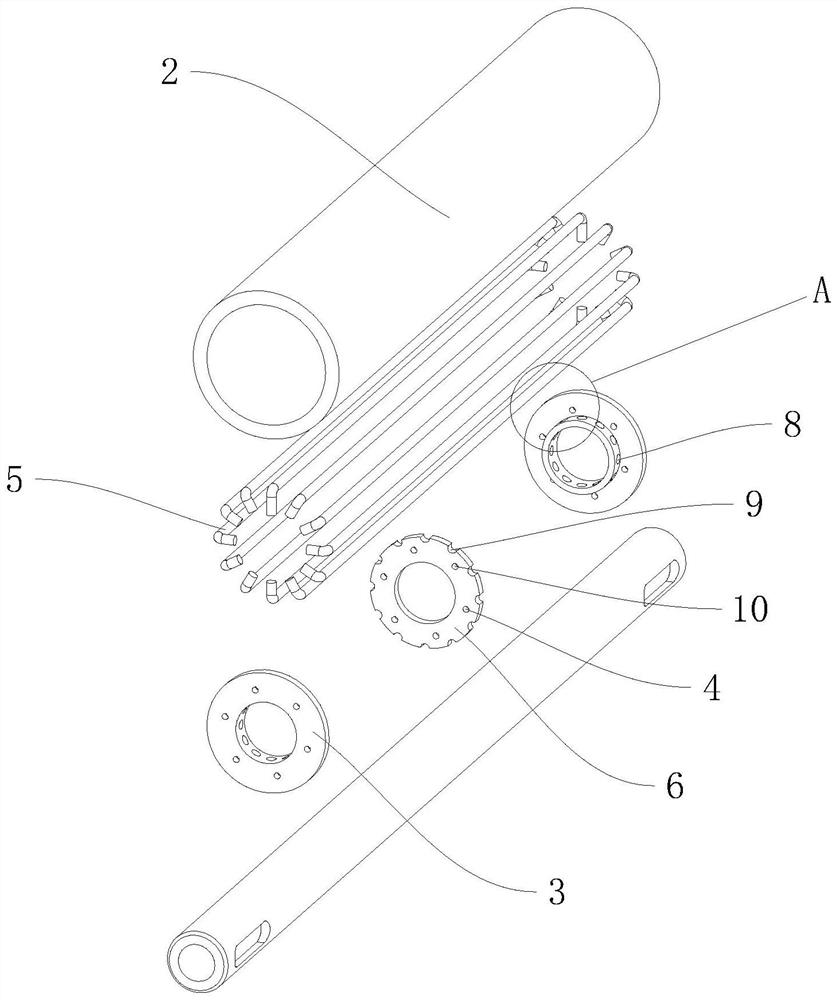

[0040] A textile roller, such as figure 1 , figure 2 and Figure 4 As shown, it includes a roller shaft 1 and a roller body 2, the roller shaft 1 is sleeved with an end sheet 3 positioned at both ends of the roller body 2, and the end sheet 3 is provided with a through hole 4 communicating with the inner chamber of the roller body 2, correspondingly A plurality of support pieces 5 that are attached to the inner wall of the roller body 2 are connected between the adjacent end pieces 3 by clamping.

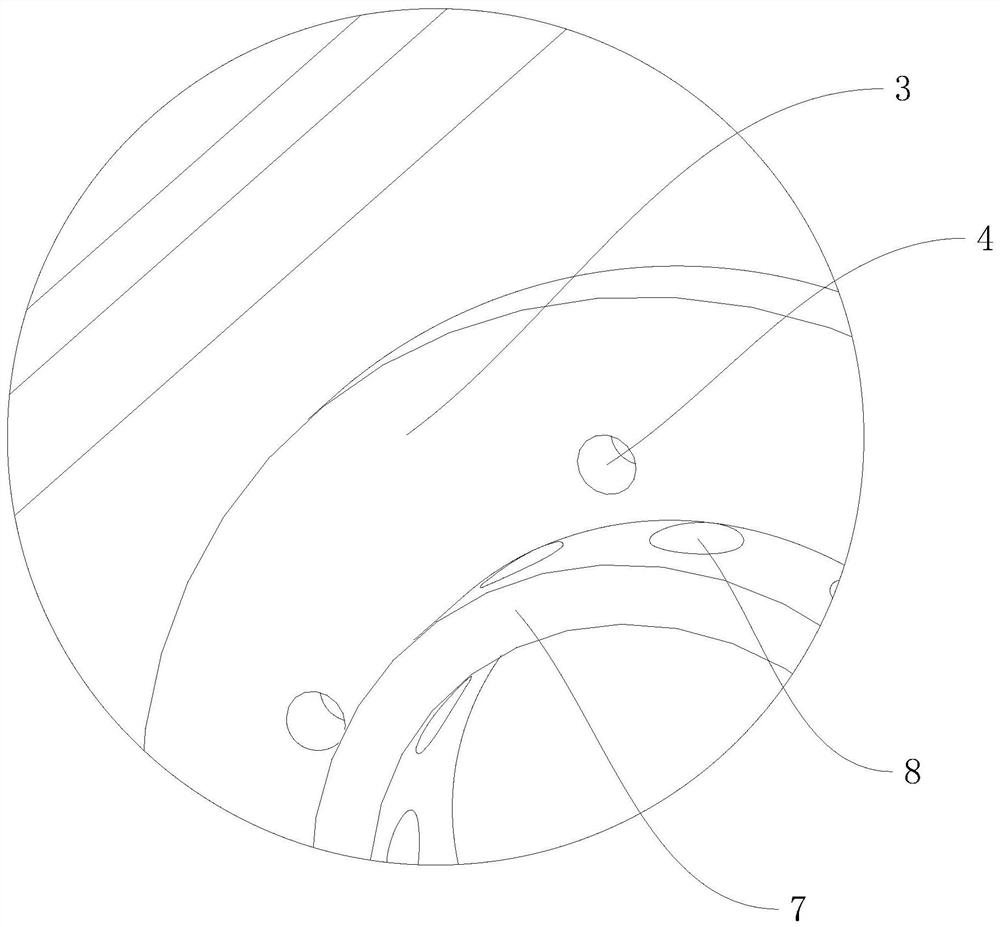

[0041] Such as Figure 2 to Figure 4 As shown, the support member 5 is U-shaped, and the ends of the end pieces 3 facing each other are welded with a circular frustum 7, and the end piece 3 and the circular frustum 7 are in a ring structure, the end piece 3 and the circular frustum 7 are arranged coaxially, and the circular frustum 7 On the outer peripheral wall, there are several slots 8 for accommodating the ends of the supports 5, and the annular arrays of several slots 8 are...

Embodiment 2

[0046] A process for textile rollers, which is used to prepare textile rollers, comprising the following steps: S1, selecting materials, selecting a roller body 2 with a cylindrical structure and a roller shaft 1 with a hollow structure, and detecting whether the outer surfaces of the roller body 2 and the roller shaft 1 are Visible cracks and pits;

[0047] S2, grinding, placing the roller body 2 and the roller shaft 1 on a grinder for grinding, removing the rust on the outer surface of the roller body 2 and the roller shaft 1, and trimming the tolerance of the outer diameter of the roller shaft 1;

[0048] S3, the blanking of the wafer, the steel plate is cut out of the connecting piece 6 in a ring structure by a wire cutting machine, and a number of arc-shaped grooves 9 distributed in a circular array and in a semicircular structure are cut out on the edge of the connecting piece 6, and cut The end piece 3 in the ring structure is produced, the connecting piece 6 and the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com