Polyamide resin composition for blow-molded articles in contact with high-pressure hydrogen, and blow-molded article using polyamide resin composition

A polyamide resin and blow molding technology, applied in the field of blow molding products, can solve problems such as damage, increased accumulation, and tank deformation, and achieve the effects of not being easily broken, suppressing local enlargement, and excellent blow molding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4、 comparative example 5、6

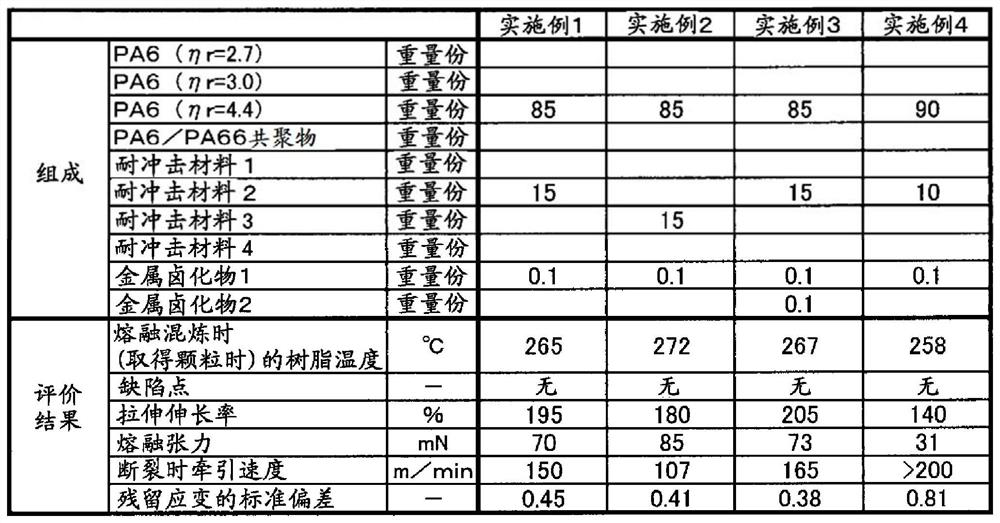

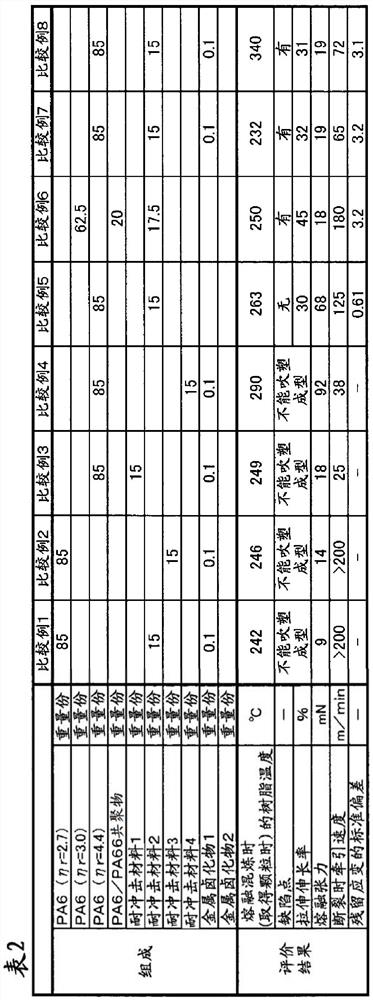

[0119] Each raw material described in Tables 1 and 2 was supplied to a twin-screw extruder (TEX30α- 35BW-7V) (L / D = 45 (In addition, L here is the length from the raw material supply port to the discharge port, and D is the diameter of the screw.)) and melt-kneaded. The strips discharged from the mold at a speed of 20 kg / h were quenched by passing through a cooling bath filled with water whose temperature was adjusted to 10° C. for 10 seconds, and then pelletized with a strand pelletizer to obtain particles. The obtained granules were vacuum-dried at a temperature of 80° C. for 12 hours with a vacuum dryer to obtain dried granules. From the obtained pellets, a parison was extruded using a blow molding machine at a cylinder temperature of 260° C., a die diameter of φ80 mm, and a core diameter of φ50 mm. Then, the mold set at 80° C. was closed and air was blown in. A blow molded product having a length of 500 mm and a diameter of φ300 mm was obtained. Using the obtained blow ...

Embodiment 1

[0120] In Example 1, kneading was performed with a composition of 85 parts by weight of PA6 (ηr=4.4) as polyamide 6 resin (A), 15 parts by weight of impact-resistant material 2 and 0.1 part by weight of metal halide 1 . The resin temperature during melt-kneading was 265°C. The average dispersion diameter of the impact-resistant material 2 obtained was 0.13 μm, and the particles were finely dispersed. In addition, the melt tension of the obtained pellets was 70 mN, and the pulling speed at breakage was 150 m / min, which were favorable. The blow molded product also had no defects, and the standard deviation of residual strain was 0.45, which was good.

Embodiment 2

[0121] In Example 2, the impact-resistant material 2 of Example 1 was changed into the impact-resistant material 3, and it was the same as Example 1 except that. The resin temperature during melt-kneading was 272°C. The melt tension of the obtained pellets was 85 mN, and the pulling speed at breakage was good at 107 m / min. The blow molded product also had no defects, and the standard deviation of residual strain was 0.41, which was good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com