Smoke deflector for integrated lampblack purification equipment for kitchen

An oil fume purification and integrated technology, applied in the direction of oil fume removal, lighting and heating equipment, application, etc., can solve the problems of oil fume leakage, oil fume inhalation, etc., achieve the effect of improving stability and avoiding thread failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

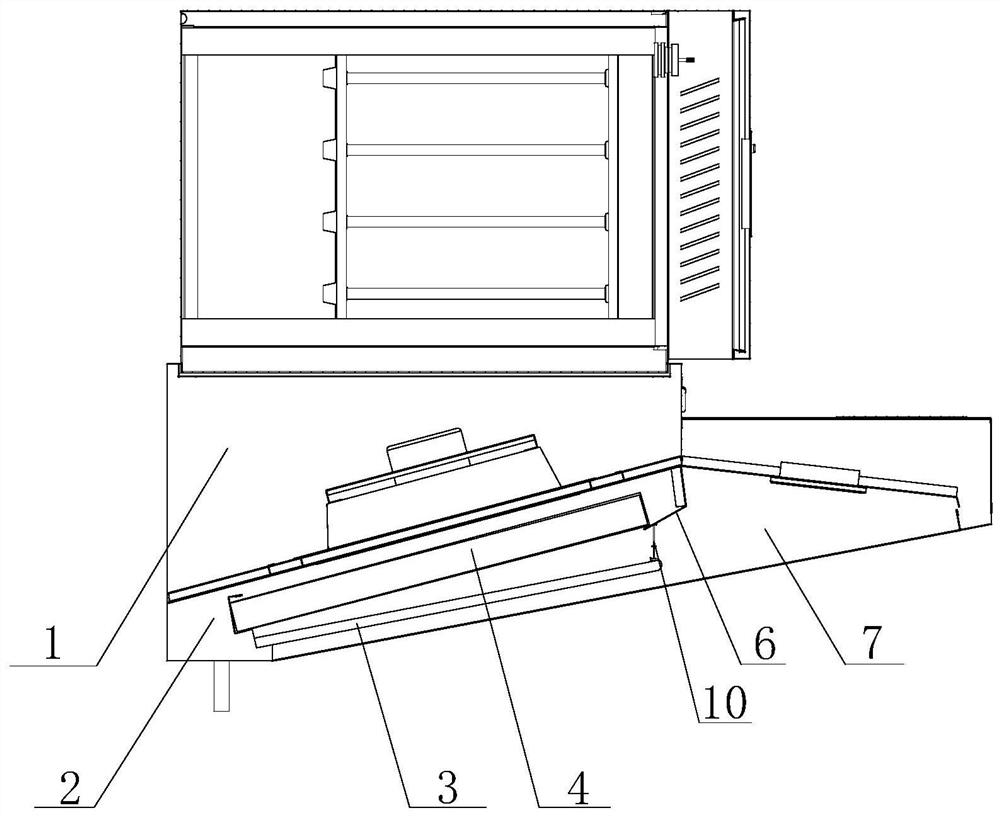

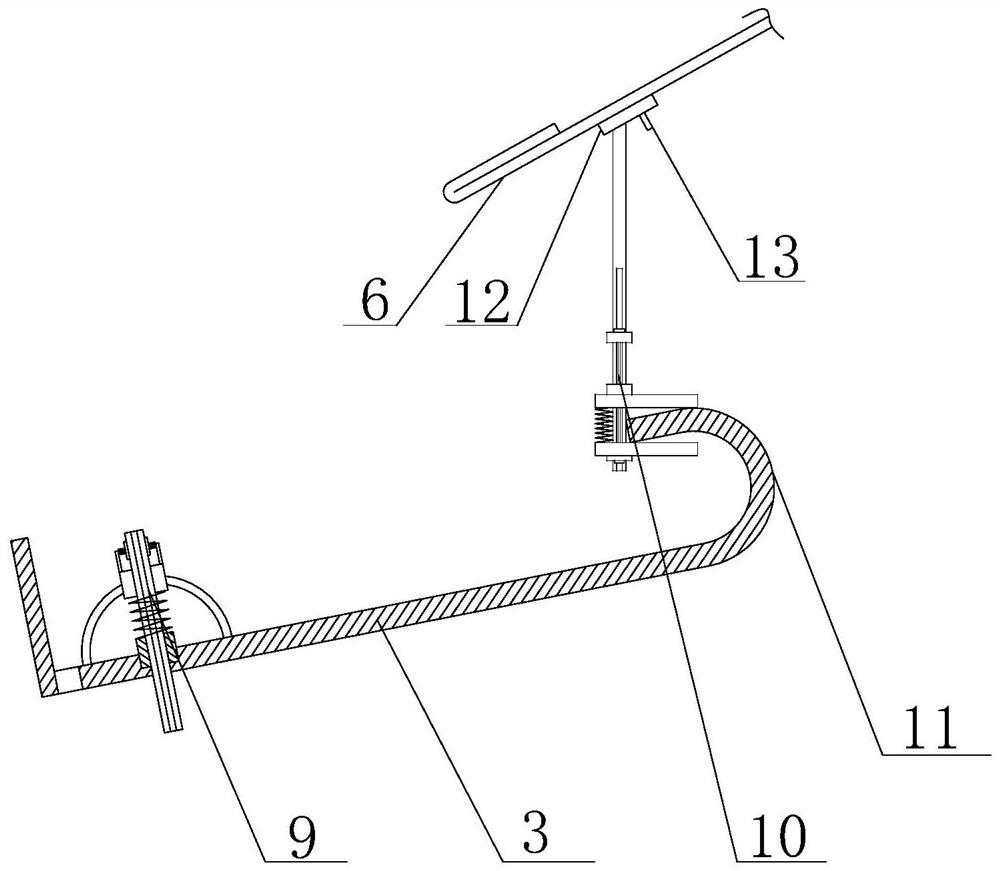

[0039] like Figure 1 to Figure 9 As shown, the present invention includes a fume collecting part 1, the fume collecting part 1 is provided with a fume processing chamber 2, a processing chamber inlet 7 is provided below the fume processing chamber 2, and an oil baffle is arranged inside the processing chamber inlet 7 4 and a slant plate 6 for placing the oil baffle plate 4, grooves are also provided on the inner wall of the inlet 7 of the processing chamber, a guide plate 3 and a connecting piece 10 are also provided in the inlet 7 of the processing chamber, and the guide plate 3 is located at the baffle Below the oil plate 4, and one end of the guide plate 3 is located on the groove, and the other end is connected with the connecting piece 10, and the connecting piece 10 is connected with the inclined plate 6; the upper surface of the guide plate 3 is provided with a square groove, and the square groove A support adjustment assembly 9 is provided in the groove, and the suppo...

Embodiment 2

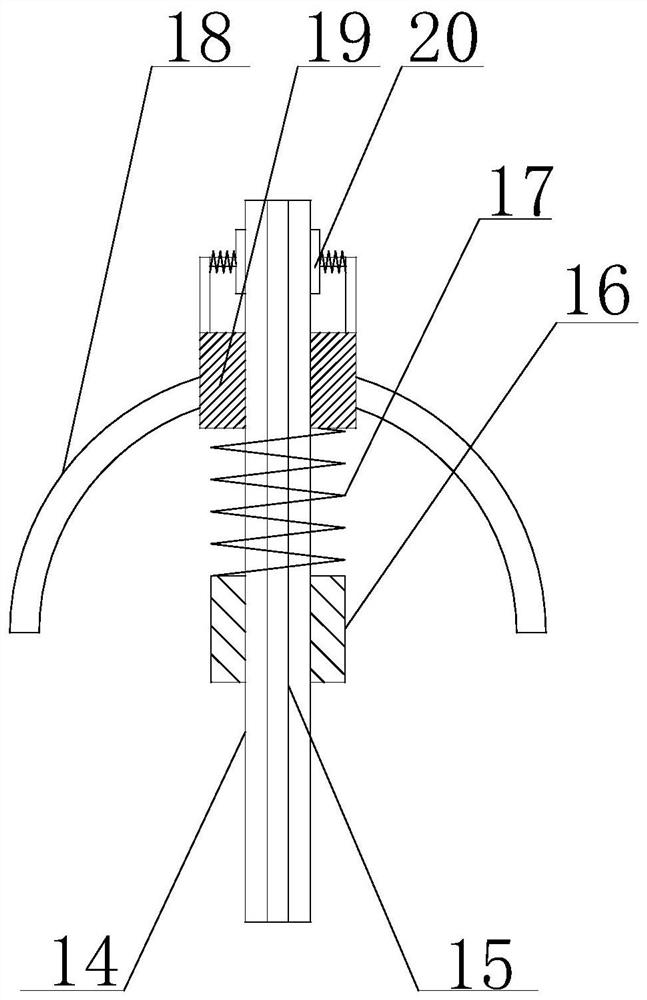

[0041] On the basis of Embodiment 1, a placement groove is also provided in the square groove of the guide plate 3, and a protrusion 16 is provided in the placement groove, the length of the protrusion 16 is greater than the depth of the placement groove, and the protrusion 16 is also provided with There is a connection hole 38 matching the support plate 14, the support plate 14 is located in the connection hole 38, the support plate 14 is also provided with a first elastic member 17, the first elastic member 17 is located between the connection block 19 and the protrusion 16 .

Embodiment 3

[0043] On the basis of Embodiment 2, both sides of the inner wall of the connecting hole 38 are provided with guide grooves 39, and both sides of the support plate 14 are provided with guide blocks 15 that match the guide grooves 39, and the guide blocks 15 Located in the guide groove 39.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com