Mechanical hydraulic precision flow control system and control method

A flow control and mechanical hydraulic technology, applied in the field of mechanical hydraulic control, can solve problems such as unable to meet stable output, unable to control pressure or flow stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

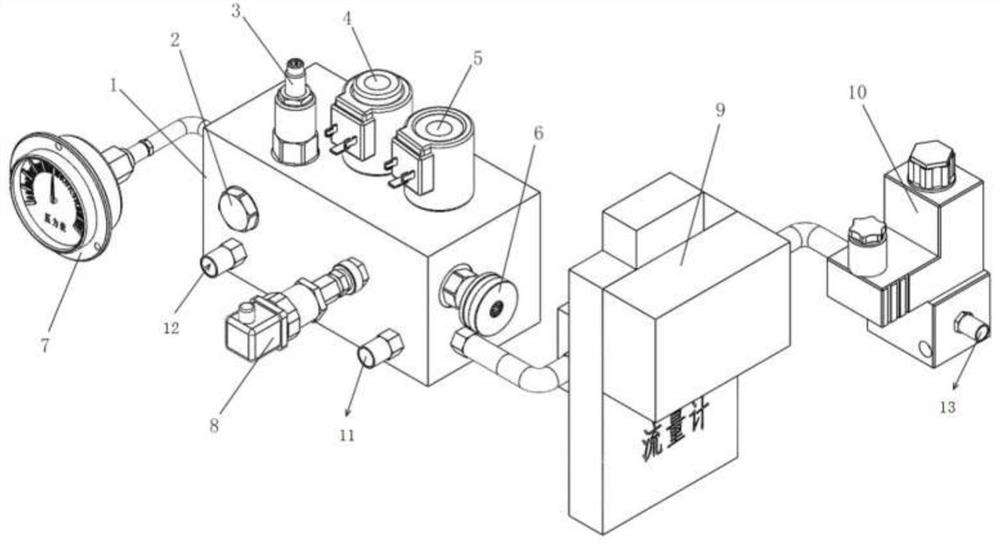

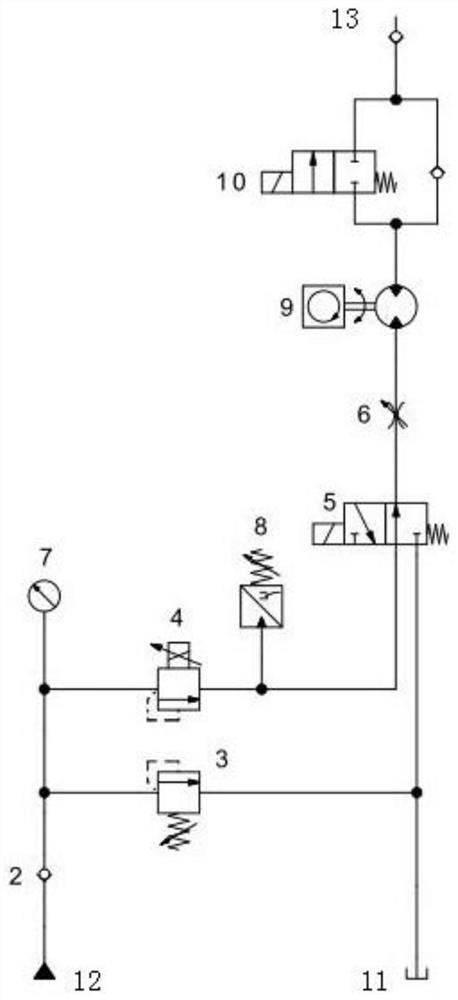

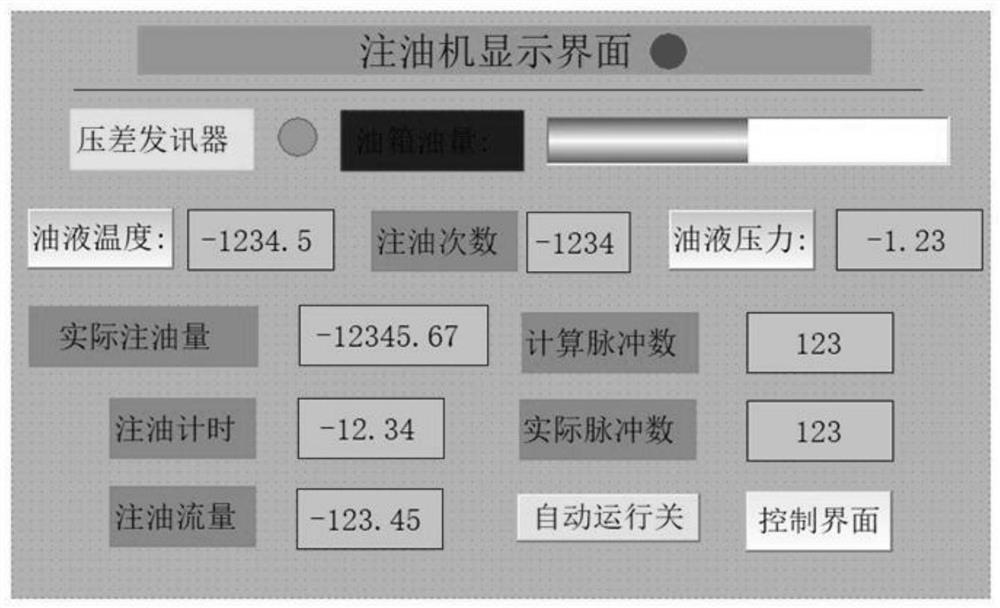

[0024] The invention provides a precision flow control system and control method for mechanical hydraulics, which are suitable for oil injection equipment, including oil circuit blocks, check valves, overflow valves, proportional pressure reducing valves, electromagnetic reversing valves, throttle valves, and pressure gauges. , pressure sensor, flow meter, electromagnetic on-off valve, the output port of the conveying equipment is connected with the inlet of the system through the pipeline, the oil flows in from the inlet of the system, and flows out from the outlet after being adjusted by the precision flow control system, so that the oil injection pressure can be stabilized. Accurate flow, uniform and adjustable flow rate.

[0025] As an embodiment of the invention, the present invention provides the following figure 1 figure 2 As shown, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com