Freezing fracturing and hydraulic punching type permeability improving and drainage promoting method for low-permeability coal seam

A low-permeability, hydraulic punching technology, applied in the direction of earthwork drilling, liquid/gas jet drilling, wellbore/well components, etc., can solve the problems of poor drainage effect and poor sealing effect, and achieve enhanced Effect of gas drainage, improvement of sealing effect, improvement of gas drainage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

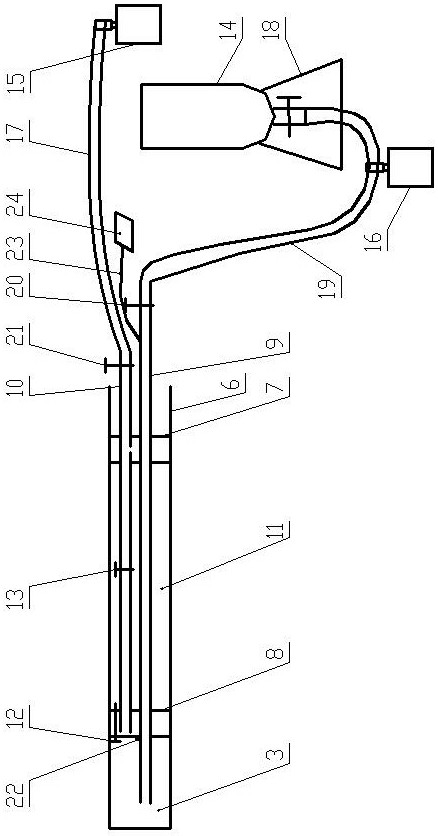

[0042] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

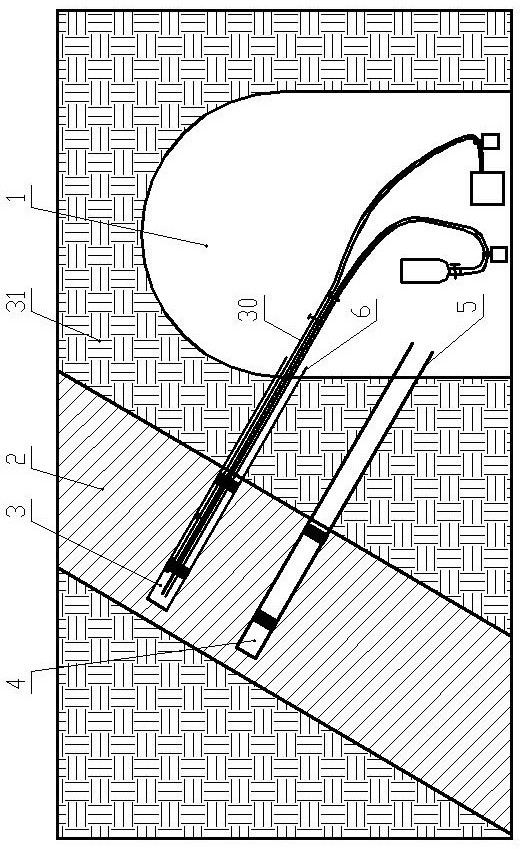

[0043] Such as Figure 1-Figure 4 As shown, the freezing fracturing collaborative hydraulic punching anti-reflection and pumping promotion method for low-permeability coal seams of the present invention comprises the following steps:

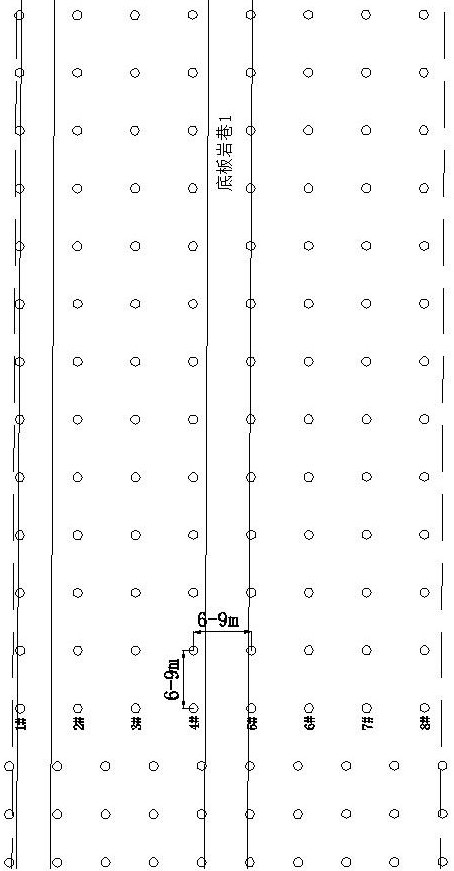

[0044] (1) Manipulate the mechanical drilling rig in the floor rock roadway 1 to drill through layers to the coal body 2 (the mechanical drilling rig first drills the rock layer 31, and then drills into the coal body 2), between the two adjacent drilling end points The distance between them is 6-9m, and the end points of each borehole are arranged in a grid-like array, and any two adjacent boreholes are respectively named injection hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com