Beam-column joint for prefabricated PEC structure system and preparation method

A technology of prefabricated assembly and beam-column joints, which is applied in the direction of building construction and construction, can solve the problems of environmental protection that do not conform to the prefabricated structure, low recyclability, and labor and material resources, and achieve high efficiency and environmental protection in the construction process. Make up for the reduction of section strength and the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

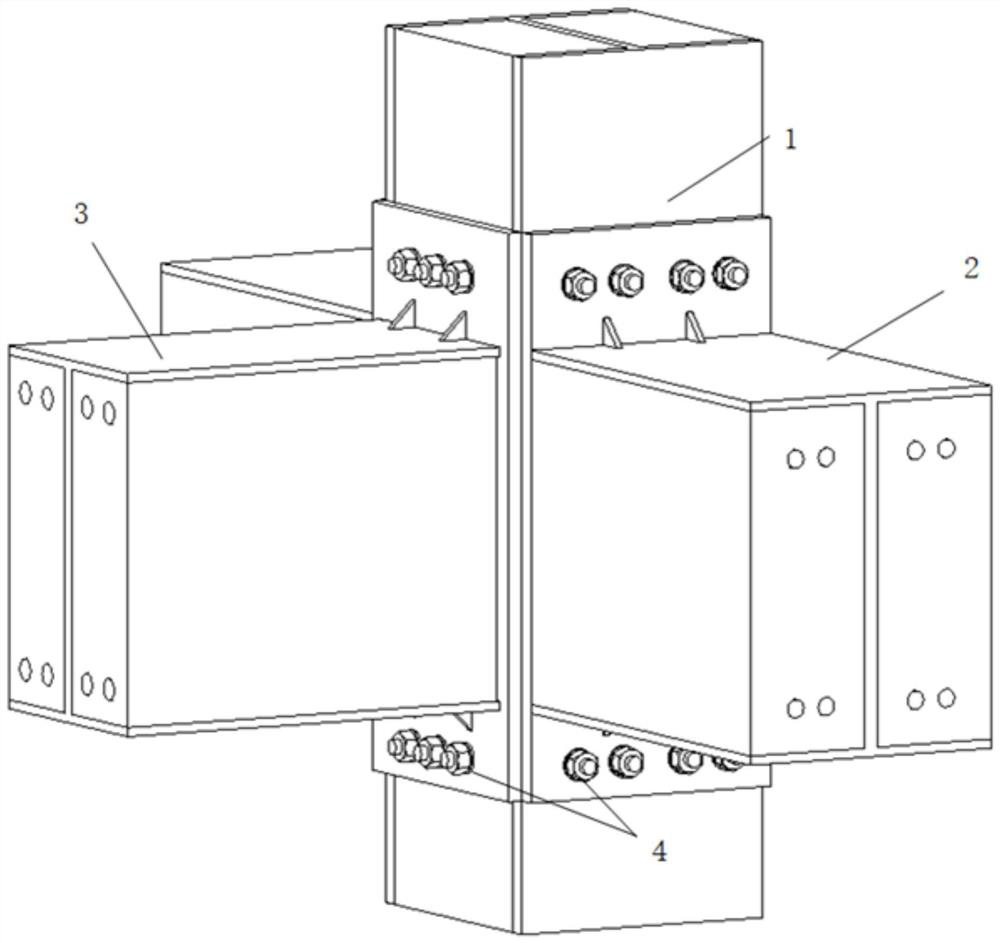

[0036] Such as figure 1 As shown, a new type of prefabricated beam-column joint for PEC system, which includes prefabricated PEC column 1, prefabricated PEC beam 2 with end plate, prefabricated PEC longitudinal beam 3 with end plate, and unilateral bolt 4.

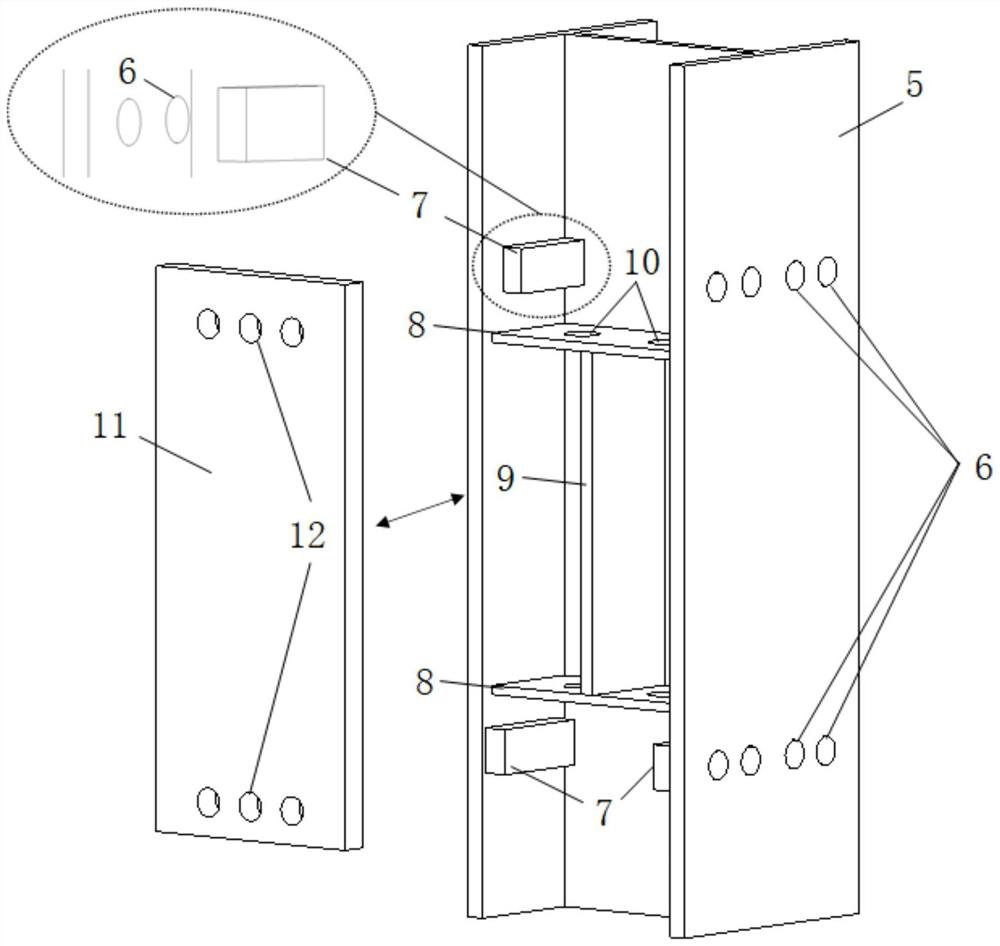

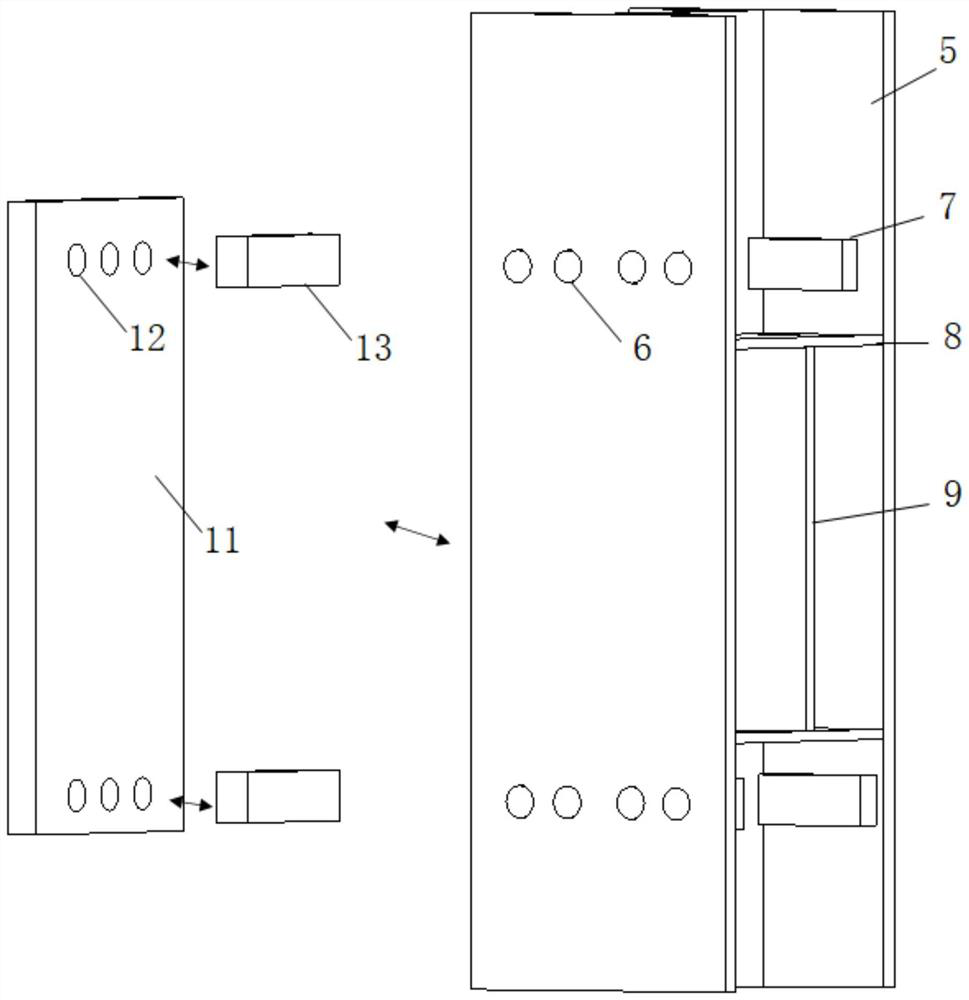

[0037] Such as figure 2 and image 3 As shown, the prefabricated PEC column 1 includes an H-shaped steel concrete column 5, a unilateral bolt hole 6 on the left and right flanges of the H-shaped steel, a channel steel 7 in the H-shaped steel flange, a transverse stiffening plate 8, a longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com