Civil engineering construction bridge support

A bridge support and civil engineering technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as inconvenient use, hidden safety hazards, and simple structure, and achieve the effects of preventing wear and tear, preventing crushing, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

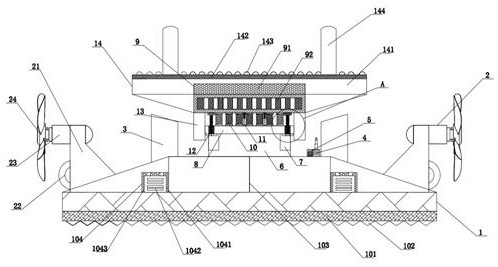

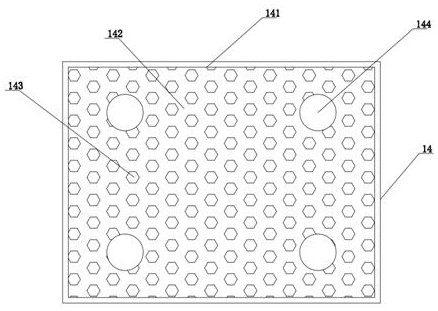

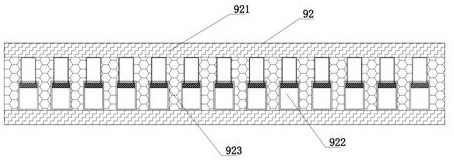

[0034] see Figure 1-5 , a bridge support for civil engineering construction, comprising a base 1, a power generating device 2 is fixedly installed on both sides of the top of the base 1, and a protective support plate 3 is fixedly connected to the inner side of the power generating device 2 on the top of the base 1, so that A signal transmitter 4 is fixedly installed on the inner side of the protective support plate 3, a DSP controller 5 is fixedly installed on the left side of the signal transmitter 4, a base block 6 is fixedly installed in the middle of the top of the base 1, and the upper end of the base block 6 Grooves 7 are opened on both sides, and the top of the base block 6 is fixedly equipped with a load-bearing plate 8, and the top of the load-bearing plate 8 is fixedly installed with shock-absorbing springs 10 at equal intervals, and the top of the shock-absorbing spring 10 is fixedly connected with a shock-absorbing mechanism 9. A pressure sensor 11 is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com