Method for manufacturing emulsified asphalt emulsion slurry and pouring longitudinal cold joint emulsion slurry of pavement

A technology of emulsified asphalt and emulsion, which is applied to roads, roads, pavement details, etc., to achieve the effect of improving efficiency, increasing service life, and ensuring standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

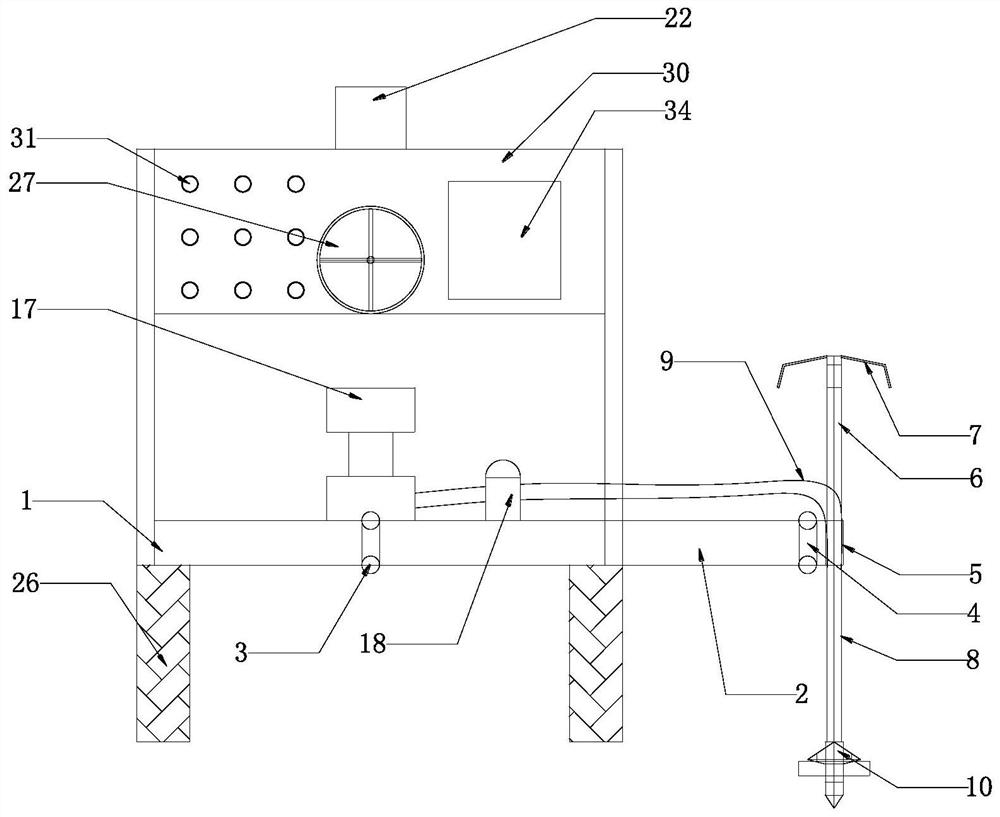

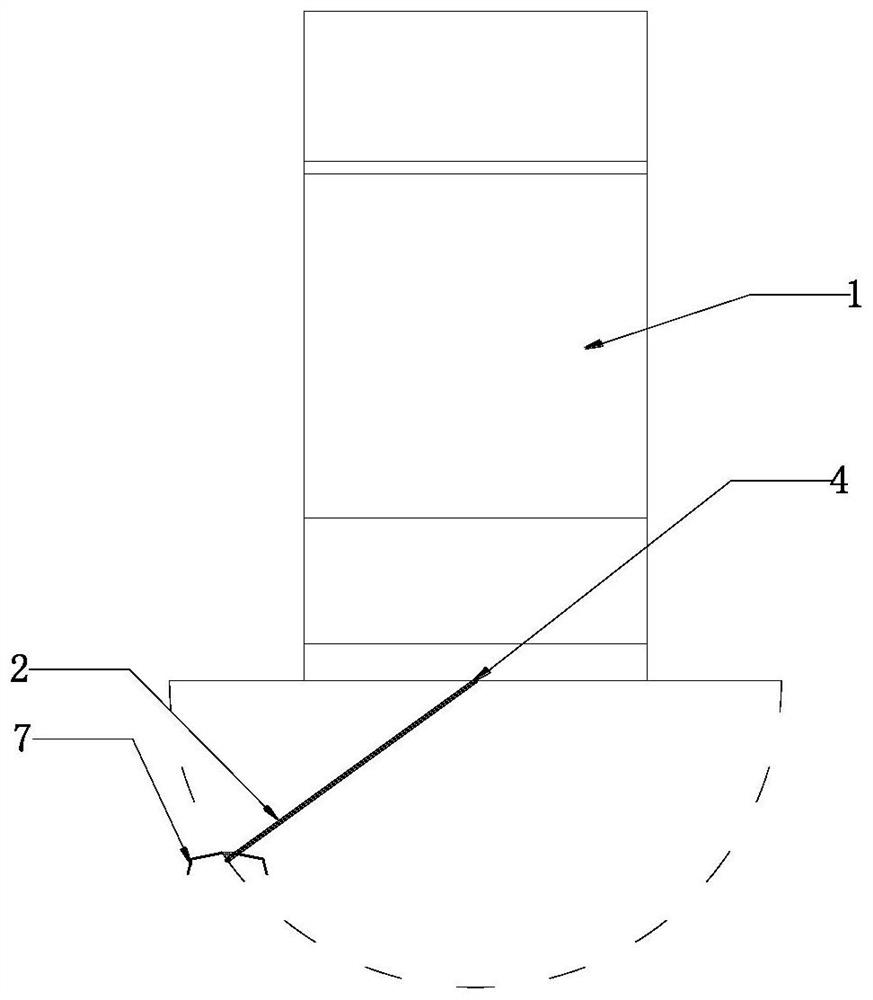

[0041] The method for producing emulsified asphalt slurry and injecting slurry into longitudinal cold joints of road surfaces according to the present invention is specifically as follows:

[0042] S1. Add the required cement and emulsified asphalt into the slurry processing device;

[0043] S2. Turn on the power and power generation device. After the power and power generation device is running stably, open the whey processing device. The whey processing device completes the mixing of the whey according to the slow-medium-fast stirring method, and maintains continuous slow stirring state;

[0044]S3. Turn on the control system. One person controls the walking and pulping of the vehicle. This person opens the walking device; the other person controls the milk slurry pouring device, which includes a drainage assembly and a pouring rod assembly. This person aligns the pouring rod assembly Open the drainage assembly at the same time, and the slurry is introduced into the groutin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com