Preparation method of epoxy resin/GO super-hydrophobic anticorrosive coating

A technology of epoxy resin and anti-corrosion coating, which is applied in epoxy resin coatings, anti-corrosion coatings, coatings and other directions, can solve problems such as difficulty in meeting, and achieve the effect of improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

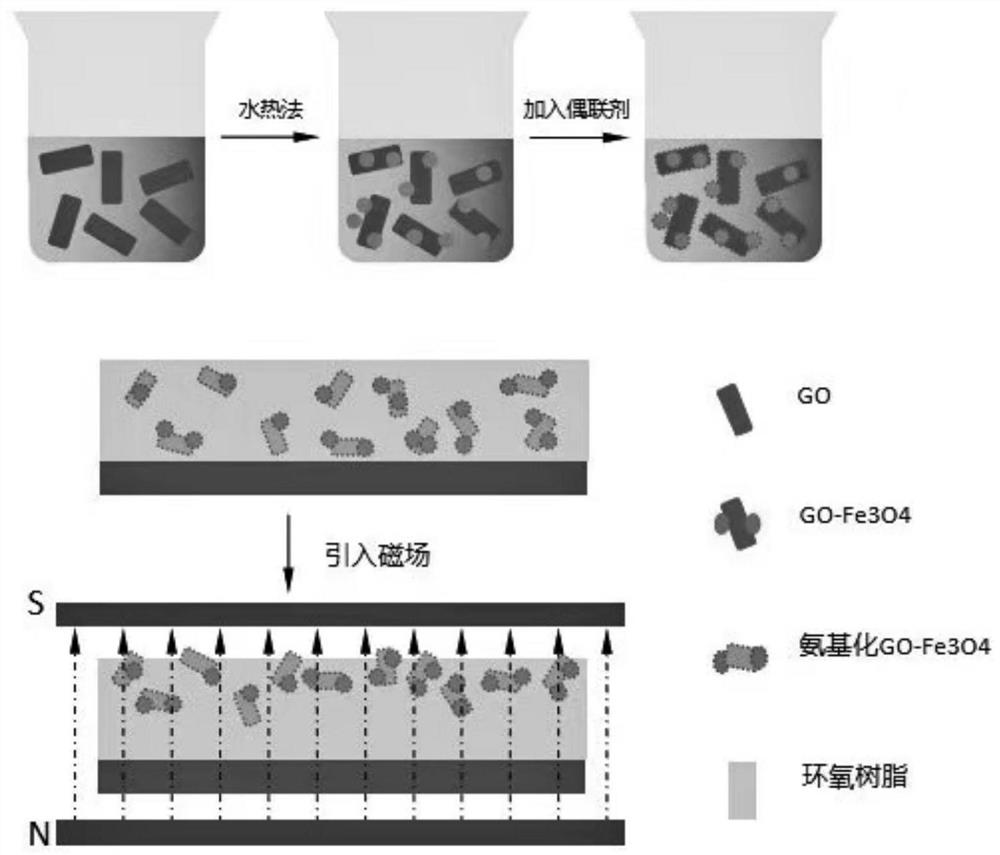

[0033] The present invention proposes a preparation method of epoxy resin / GO superhydrophobic anti-corrosion coating, the method steps are as follows:

[0034] S1. Preparation of GO-Fe 3 o 4 Nanoparticles: a certain quality of polyvinylpyrrolidone (PVP), 5.213g ferrous chloride tetrahydrate (FeCl 2 4H 2 O), ammonia water was uniformly dissolved in 100 mL of distilled water, and after stirring at a low speed for 30 min, 6.611 g of graphene oxide (GO) aqueous dispersion was added, and the hydrothermal reaction was carried out at 100° C. for 5.0 h. After washing with distilled water and ethanol three times and freeze-drying, GO-Fe 3 o 4 Nanoparticles.

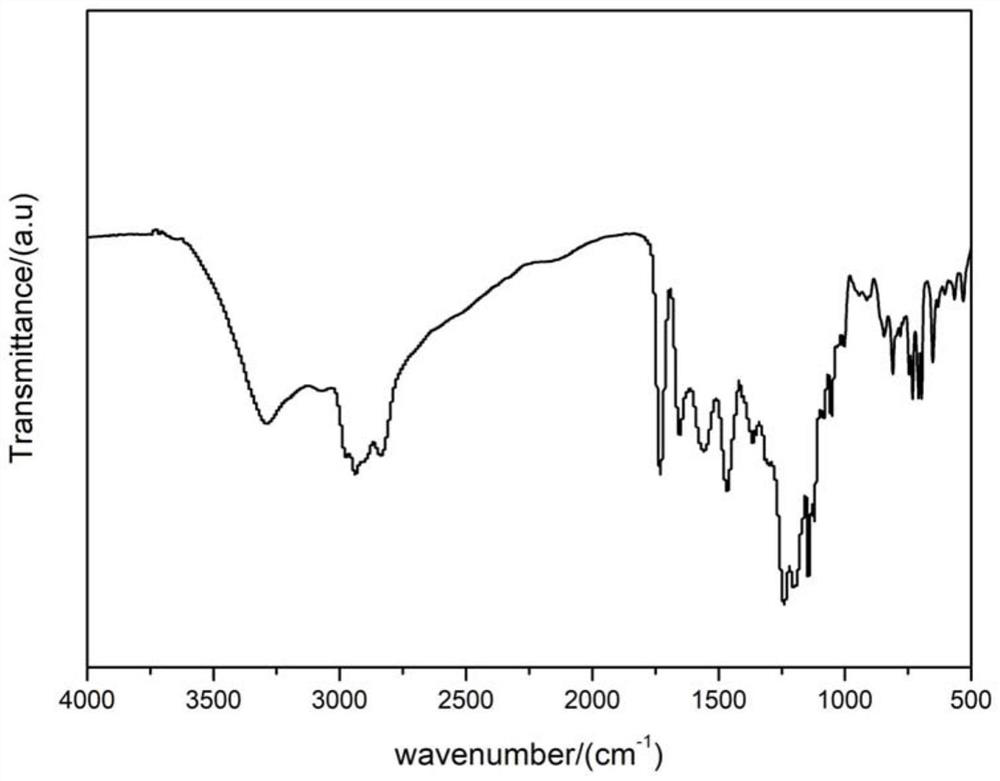

[0035] S2, GO-Fe 3 o 4 Amination of nanoparticles: 2.513g GO-Fe 3 o 4 Nanoparticles were dispersed into 100mL of ethanol-water mixed solution, ultrasonically dispersed for 30min, then 5.012g of γ-aminopropyltriethoxysilane (KH550) was added, and stirred at a medium speed at 50°C for 5.0h. After washing with water and eth...

Embodiment 2

[0040] The implementation method steps in this embodiment are the same as those in Embodiment 1. However, the technical parameters are different. The difference between the two is that in S4, a 240mT magnet is suspended at 3cm from the coating surface during the film formation process.

Embodiment 3

[0042] The implementation method steps in this embodiment are the same as those in Embodiment 1. However, the technical parameters are different. The difference between the two is that in S4, a 240mT magnet is suspended at 4cm from the coating surface during the film formation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com