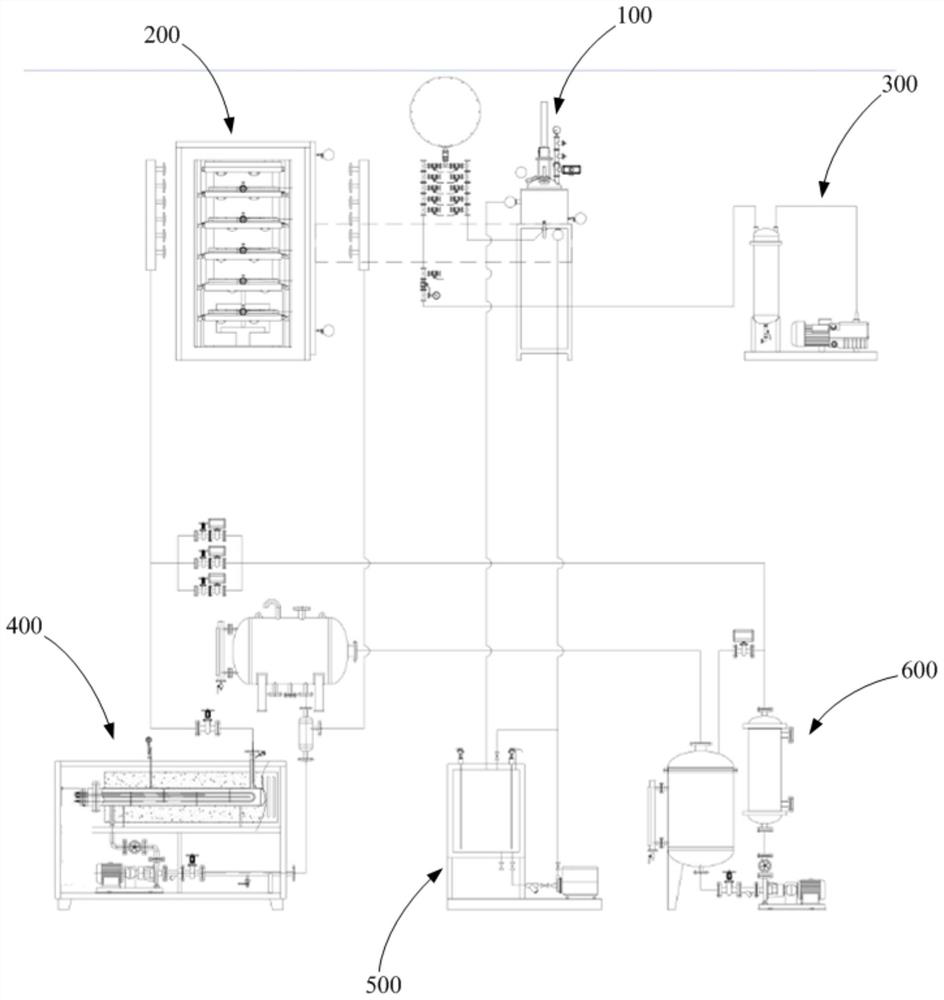

System for preparing absorbable polyester and method thereof

A polyester and polymer technology, which is applied in the field of systems for preparing absorbable polyesters, can solve the problems of poor melt stability of polyglycolic acid, large internal and external differences of solids, and uneven heat conduction of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

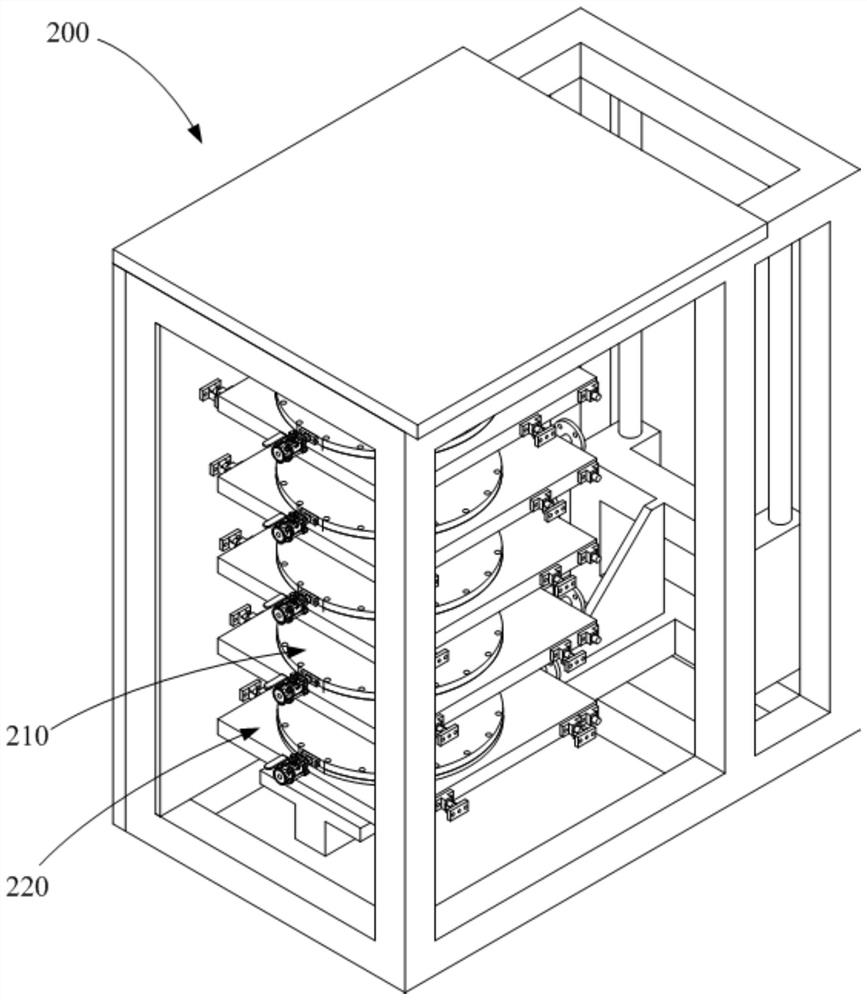

[0044]The method for preparing absorbable polyester of the present invention adopts bulk polymerization, and the advantage of bulk polymerization over melt polymerization is lower reaction temperature: due to the moderate temperature, side reactions occur to a much smaller extent. Side reactions during polymerization are detrimental on the one hand, since they cause chain termination in the growth reaction, thereby limiting the molecular weight in the polymer, and the molecular weight distribution as well as the residual monomer content are also broadened. Therefore, absorbable polyesters with very high molecular weight can only be produced by bulk polymerization and not in the molten state. The high reaction temperature of melt polymerization also has the disadvantage that the resulting polymer may have some discoloration. These impurities produced at high temperatures are often bound to the polymer and therefore cannot be removed from the product in subsequent purification s...

Embodiment 1

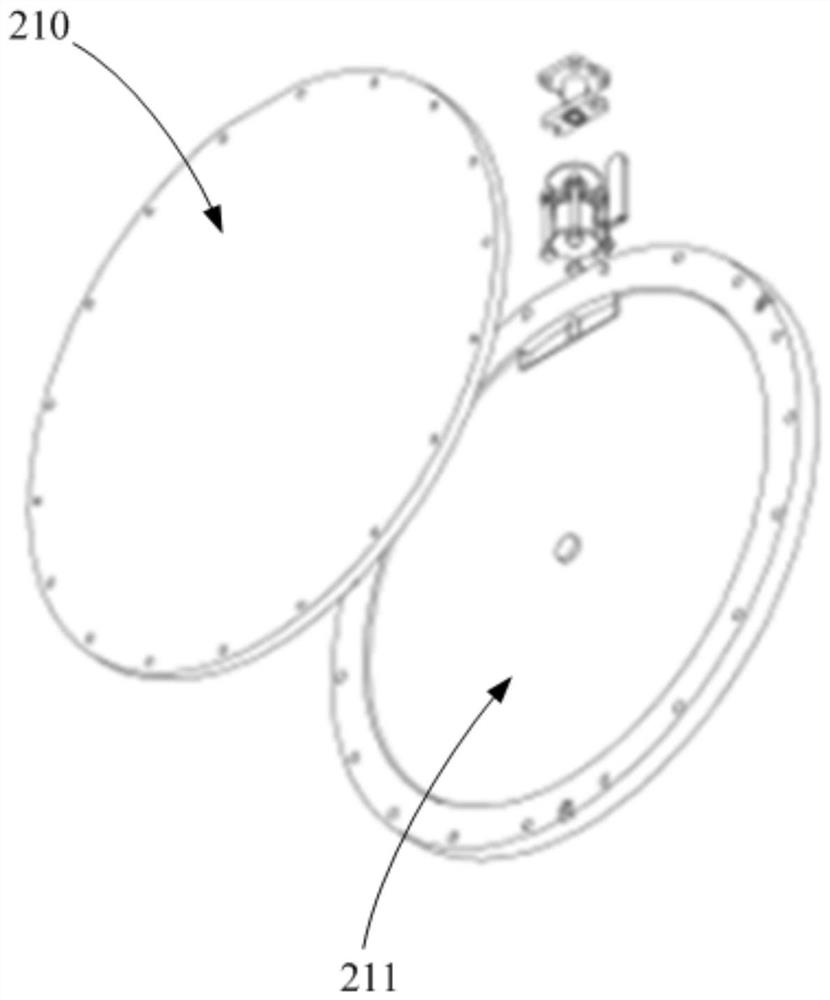

[0089] First, add 2KG of L-lactide (purity above 99.5%), 0.3g of stannous octoate and 3mL of water into the melting tank, then fill it with nitrogen protection and heat and stir. The heating temperature range is 105-110°C. After the solid powder is completely melted, the molten liquid is evenly discharged into the polymerization reactor, filled with nitrogen protection and the valve of the reactor feed port is closed, and the temperature of the polymerization reaction heating plate is set at 170-175°C. L-lactide melt undergoes ring-opening polymerization under the joint action of temperature, catalyst and initiator. When the temperature rises to a constant value, start counting. After 4 hours of heat preservation at this temperature, switch to a low-temperature oil circuit. The temperature of the low-temperature oil circuit is set at 115-120°C. After 8 hours of heat preservation, the reaction is over, and the temperature is naturally lowered, and the temperature is removed from...

Embodiment 2

[0097] Add 5KG of glycolide (GA), 0.25g of stannous chloride (SnCl2) and 5mL of n-dodecyl alcohol into the melting tank, then fill it with nitrogen protection and heat and stir. The heating temperature ranges from 100 to 105°C. After the solid powder is completely melted, the molten liquid is evenly discharged into the polymerization reactor, filled with nitrogen protection and the valve of the reactor feed port is closed, and the temperature of the polymerization reaction heating plate is set at 175-180°C. Glycolide undergoes ring-opening polymerization under the combined action of temperature, catalyst and initiator. When the temperature rises to a constant value, start timing, and switch to the low-temperature oil circuit after holding at this temperature for 2 hours. The temperature of the low-temperature oil circuit is set at 115-120 °C. Take out the yellow sheet-shaped finished polyglycolide (PGA), and then make the PGA into irregular solid particles through physical cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com