Preparation method of hydrophobic antifouling ground coat slurry

An anti-fouling and primer technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of high preparation cost of superhydrophobic coating, only focusing on superhydrophobicity, and complicated process. , to achieve excellent anti-adsorption performance, enhanced interaction force, and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

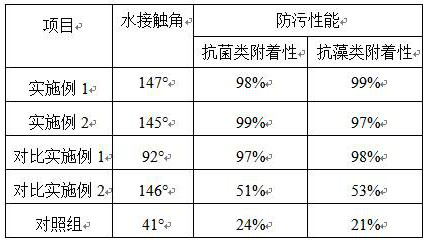

Examples

Embodiment 1

[0027] A method for preparing a hydrophobic anti-fouling bottom glaze slurry, characterized in that it comprises the following steps, the following raw materials are by weight:

[0028] (1) Preparation of hydrophobic sol materials:

[0029] Add absolute ethanol to 10 parts of modified epoxy resin at a ratio of 1:55 to ultrasonically disperse and dissolve, place it under magnetic stirring at 60°C, add 70 parts of ammonia water to react at constant temperature for 2 hours, then add 10 parts of hydrogen-containing silicone oil, 1 part of dilauric acid dilaurate Butyl tin was stirred for hydrophobic modification for 4 hours to obtain a hydrophobic sol material;

[0030] Among them, the preparation of modified epoxy resin: Add absolute ethanol to 5 parts of epoxy resin E-44 at a ratio of 1:10, ultrasonically disperse and dissolve, place it under magnetic stirring at 60°C, add 10 parts of KH550 to react at constant temperature for 2 hours, rotate Evaporated and separated to obtain ...

Embodiment 2

[0039] A method for preparing a hydrophobic anti-fouling bottom glaze slurry, characterized in that it comprises the following steps, the following raw materials are by weight:

[0040](1) Preparation of hydrophobic sol materials:

[0041] Add absolute ethanol to 1:55 parts of modified epoxy resin to ultrasonically disperse and dissolve, place it under magnetic stirring at 65°C, add 120 parts of ammonia water to react at constant temperature for 1 hour, then add 15 parts of hydrogen-containing silicone oil, 2 parts of dilauric acid dilaurate Butyl tin was stirred for hydrophobic modification for 3 hours to obtain a hydrophobic sol material;

[0042] Among them, the preparation of modified epoxy resin: Add absolute ethanol to 10 parts of epoxy resin E-44 at a ratio of 1:10, ultrasonically disperse and dissolve, place it under magnetic stirring at 65°C, add 20 parts of KH550 to stir at constant temperature for 1 hour, and rotate Evaporated and separated to obtain modified epoxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com