Method for preparing silica aerogel using industrial solid waste fly ash and silica aerogel prepared by the method

A silicon dioxide and industrial solid waste technology, applied in chemical instruments and methods, solid waste management, aluminum hydroxide preparation, etc., can solve problems such as industrial solid waste fly ash environmental pollution, and achieve high-value utilization 、Solve the effect of high preparation cost and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

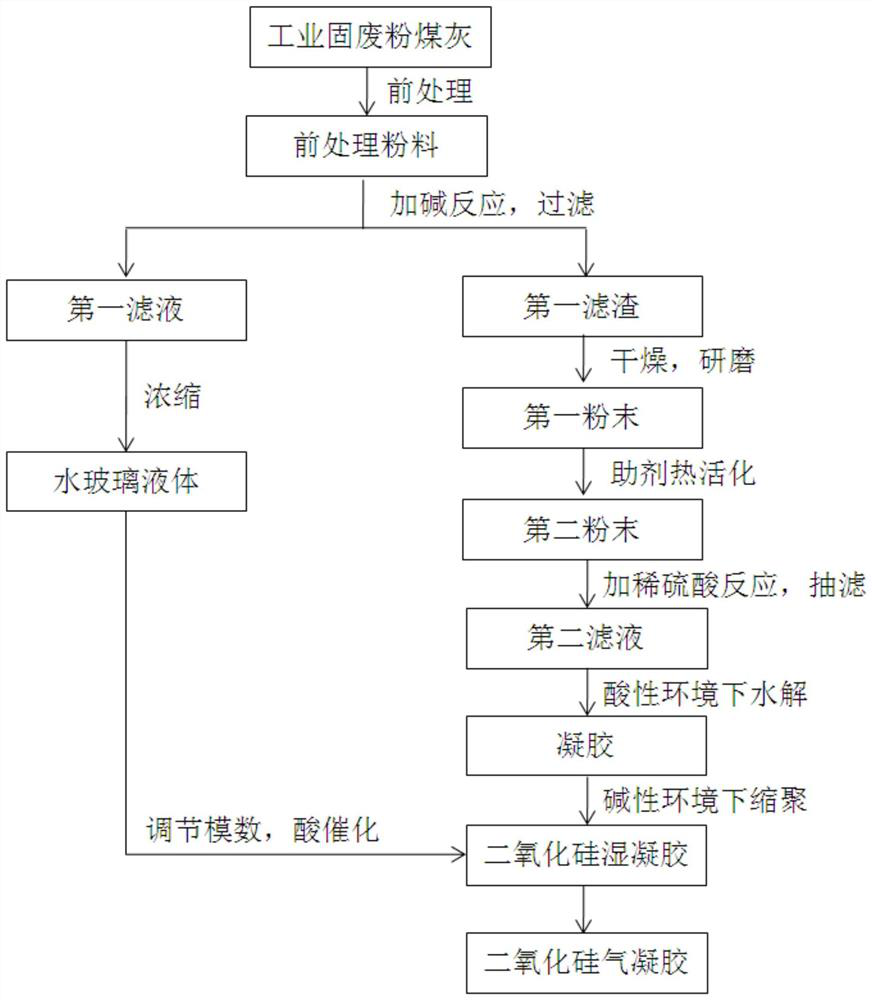

Method used

Image

Examples

Embodiment 1

[0075] The fly ash is vibrated and sieved through a 100-mesh standard sieve, and then a magnetic separator is used to magnetically separate and separate the magnetic substances in the fly ash. The composition of fly ash after magnetic separation is as follows: in terms of mass percentage, silica 54.76%, alumina 24.56%, calcium oxide 4.85%, ferric oxide 4.79%, titanium dioxide 1.85%; the rest is loss on ignition The amount and components that have no effect on the process and product are not listed here.

[0076] Add water and stir the above-mentioned powder material after magnetic separation to dissolve it into a slurry with a mass concentration of 20%. After stirring for 10 minutes under the condition of 300 r / min, let it stand for stratification, and separate and extract the bleach in the fly ash. Beads and precipitation ash components; the floating beads are collected and used for other purposes; the precipitation ash is dried at 100 ° C for 2 hours, and the dry powder is g...

Embodiment 2

[0084] In the pretreatment of fly ash, the concentration of the slurry prepared during washing was 25%. After stirring for 8 minutes at 300 r / min, it was left to stand for stratification, and the floating beads and ash components of fly ash were separated and extracted. Dry at 105°C for 2.5h, and grind the dry powder for later use.

[0085] In the pre-desilication treatment, a sodium hydroxide solution with a mass concentration of 25% needs to be prepared, and the liquid modulus of the water glass obtained by the treatment is 0.68; the filter cake is dried at a temperature of 105 ° C for 2.5 hours, and the dried powder is ground for later use. The modulus of water glass is increased to above 3.0, and dilute sulfuric acid with a concentration of 2 mol / L is added for acid catalysis to obtain a silica wet gel.

[0086] The thermal activation of the auxiliary agent is to weigh a certain amount of desilication slag and sodium carbonate according to the mass ratio of 1:0.9, mix the ...

Embodiment 3

[0091] In the pretreatment of fly ash, the concentration of the slurry prepared during washing is 30%. After stirring for 10 minutes at 300 r / min, it is left to stand for stratification, and the floating beads and ash components of fly ash are separated and extracted. Dry at 110°C for 3 hours, and grind the dry powder for later use.

[0092] In the pre-desilication treatment, a sodium hydroxide solution with a mass concentration of 30% needs to be prepared, and the liquid modulus of the water glass obtained by the treatment is 0.75; the filter cake is dried at a temperature of 110 ° C for 3 hours, and the dried powder is ground for later use. The modulus of water glass is increased to above 3.0, and dilute sulfuric acid with a concentration of 6 mol / L is added for acid catalysis to obtain a silica wet gel.

[0093] The thermal activation of the auxiliary agent is to weigh a certain amount of desiliconization slag and sodium carbonate according to the mass ratio of 1:1, mix the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com